Method for microwave hydrolysis of pollen

A technology of pollen and microwave, which is applied in the fields of pharmaceutical formulations, medical raw materials derived from gymnosperms, cosmetics, etc., to achieve high soluble sugar content and ensure pure naturalness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

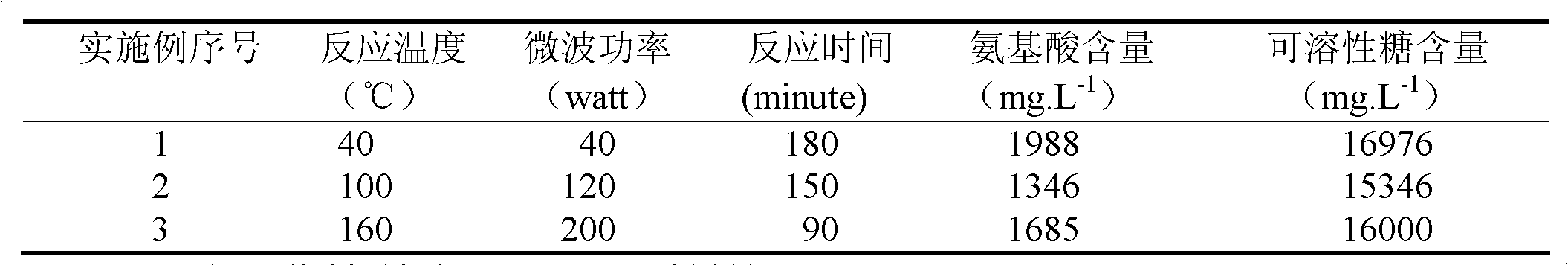

Embodiment 1

[0022] Put 2.000g of commercially available masson pine unbroken pollen (Hangzhou Wansan Health Biological Technology Development Co., Ltd.) and 20g of pure water (double distilled water) into a microwave digestion apparatus (CEM American Pei'an Company) at 40°C, microwave After reacting with a power of 40W for 15 minutes, turn off the microwave digester. After 10 minutes, turn on the reactor to set a reaction time of 180 minutes. After the reaction is over, the reaction solution is filtered after cooling, the filter cake is vacuum-dried and placed in a low-temperature dry place for later use; the filtrate is automatically sampled with amino acids The content of amino acids and soluble sugars in the filtrate was analyzed by an analyzer (L8900 Hitachi, Japan) and an ultraviolet spectrophotometer (UV-2501PC, Shimadaki, Japan). The results are shown in Table 1. The degree of pollen hydrolysis was 335.5 mg / g. After sampling, the filtrate is subjected to microwave sterilization (the ...

Embodiment 2

[0027] The reaction conditions were set to a temperature of 100° C., a microwave power of 120 W, and a reaction time of 150 minutes. The experimental method was the same as in Example 1. The experimental results are shown in Table 1. The degree of pollen hydrolysis was 350.6 mg / g.

Embodiment 3

[0029] The reaction conditions were set to a temperature of 160° C., a microwave power of 200 W, and a reaction time of 90 minutes. The experimental method was the same as in Example 1. The experimental results are shown in Table 1. The degree of pollen hydrolysis was 451.4 mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com