Power socket connector

A technology for power sockets and connectors, which is applied to contact parts, bases/shells, etc., and can solve problems such as potential safety hazards, failure of elastic recovery, and poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

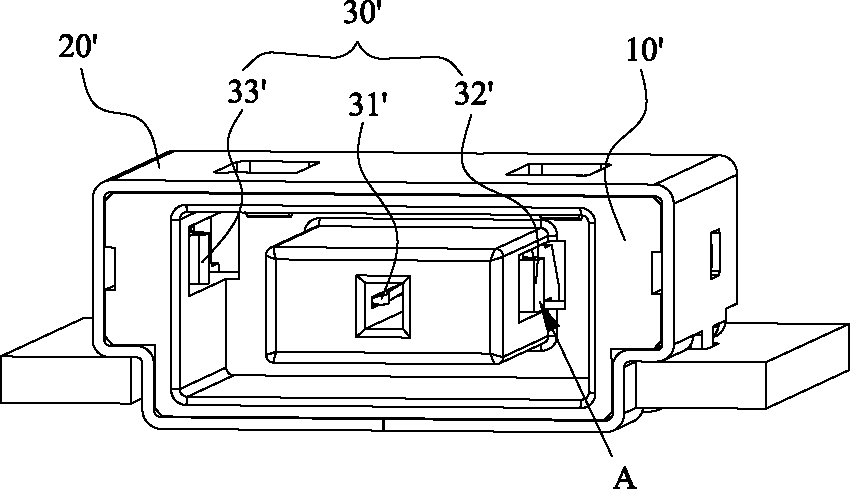

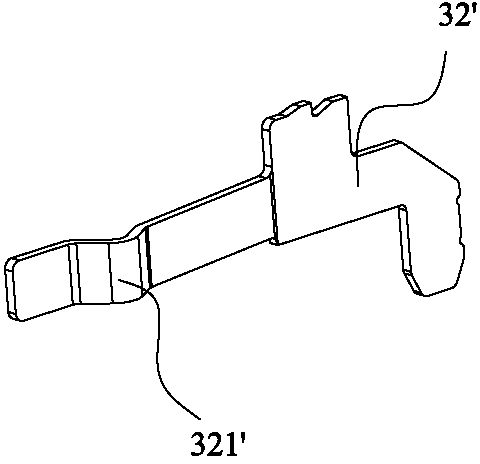

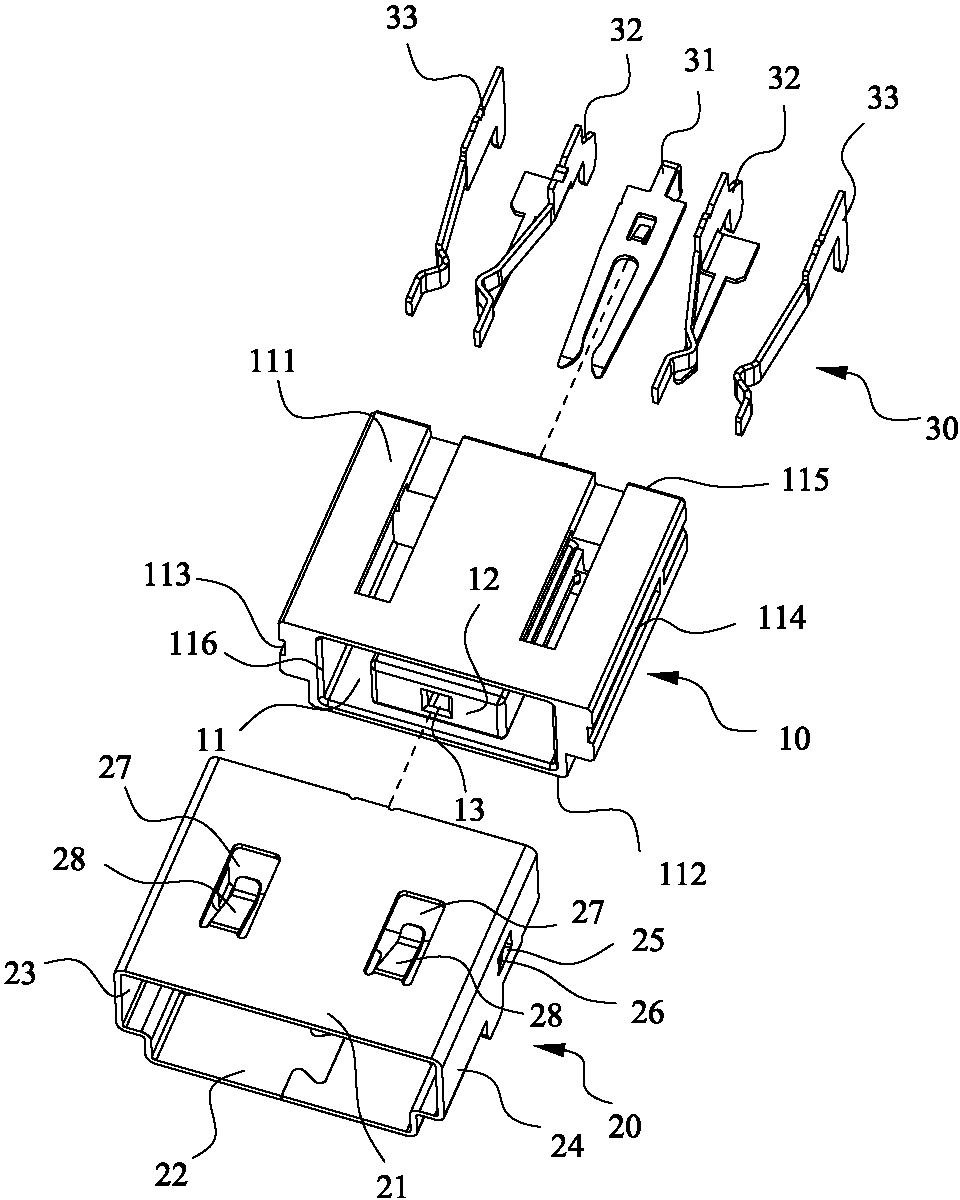

[0051] First, please refer to Figure 3 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention, which includes an insulating body 10 , a shielding shell 20 covering the insulating body 10 and a terminal group 30 installed in the insulating body 10 .

[0052]Wherein, the insulating body 10 is made of plastic material, and has an accommodating space 11 for inserting a matching power plug (not shown), the accommodating space 11 is composed of a top wall 111 , a bottom wall 112 , and a left side wall 113 , a right side wall 114 and a rear end surface 115 , and the front end of the accommodating space 11 is an opening 116 . In addition, a tongue plate 12 extends from the rear end surface 115 of the insulating body 10 , and a central insertion slot 13 penetrating through the rear end surface 115 of the insulating body 10 is provided on the front end surface of the tongue plate 12 . There are first insertion slots 14 located on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com