Pipe-end induction-based magnetic particle flaw detector

A technology of induction magnetism and flaw detection machine, applied in the direction of material magnetic variable, etc., can solve problems such as complex structure, large machine shape, uneven magnetic field, etc., and achieve the effect of high sensitivity, small machine shape, and no blind zone in the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Describe the present invention in detail below in conjunction with accompanying drawing:

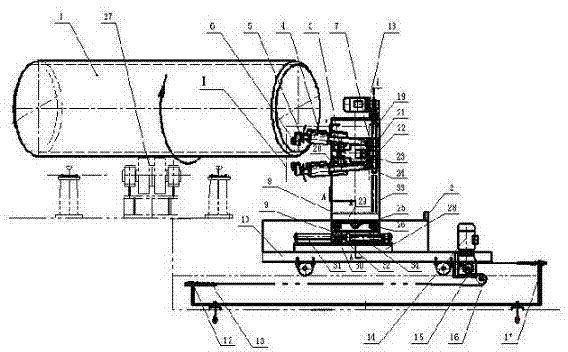

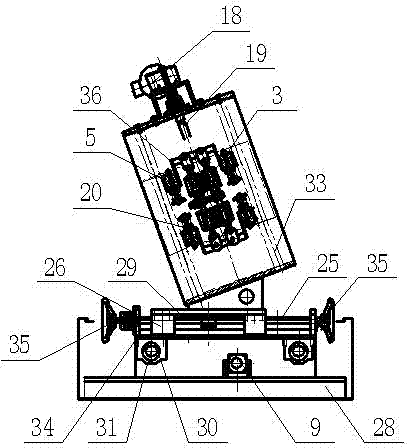

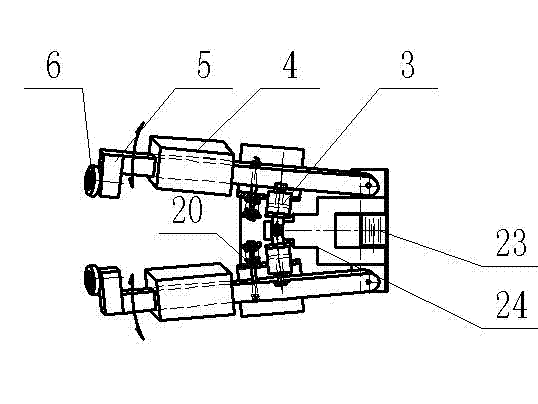

[0021] Such as Figure 1-3 As shown, the pipe end induction magnetic particle flaw detection machine includes the electrical control system, spraying system, circumferential magnetization power supply, longitudinal magnetization power supply, lighting device, auxiliary device for entering and exiting the large oil pipe workpiece 1 to be detected, and the driving workpiece support used in the prior art. The roller 27 drives the rotating device of the detected large-scale oil pipe workpiece 1; it also includes a mobile reducer 14, a traction chain tension frame 12, a traction chain 13, a driving sprocket 15, and a driven sprocket for the fast movement of the drive frame 10. 16. Chain tensioning bolts 17; the magnetic suspension liquid collecting tank 2 is arranged on the top of the frame 10; the magnetic suspension liquid collecting tank 2 is equipped with a lower frame 28, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com