Method for testing double-direction torque of eddy current dynamometer

An eddy current dynamometer and torque testing technology, applied in power metering, measuring device, torque metering and other directions, can solve the problems of zero point drift of tensile force, inability to test bidirectional torque, etc., achieve high cost performance, improve torque measurement accuracy and Simple and practical effect of test efficiency and measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further introduced below in combination with specific embodiments.

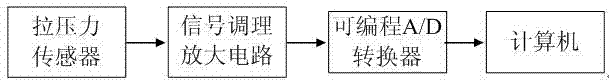

[0024] Such as figure 1 Shown is the principle diagram of the two-way torque test circuit of the eddy current dynamometer of the present invention. As can be seen from the figure, the circuit includes a signal conditioning amplifier circuit connected to the signal output terminal of the tension pressure sensor, and the output terminal of the signal conditioning amplifier circuit is connected to a A programmable A / D converter, the signal output of the programmable A / D converter is connected with the signal input of the computer.

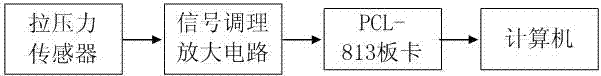

[0025] Such as figure 2 As shown, the programmable A / D converter in this embodiment adopts the Advantech PCL-813 board, and the PCL-813 board is inserted into the ISA slot of the computer, and the signal output of the PCL-813 board communicates with the computer through the ISA bus signal input connections. The board is installed in the ISA s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com