Lifting frame device and circular cooler with same

A hanger and sealing device technology, applied in the field of iron and steel smelting, can solve problems such as cumbersome operation and poor safety, and achieve the effects of improving operation safety, facilitating operation, and reducing operating height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

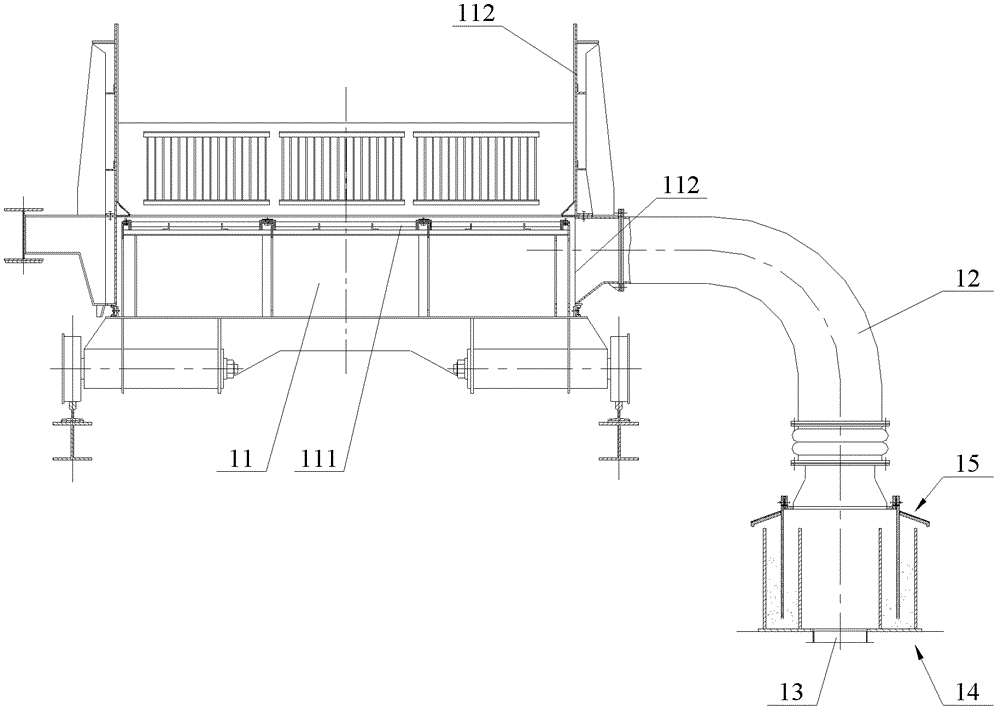

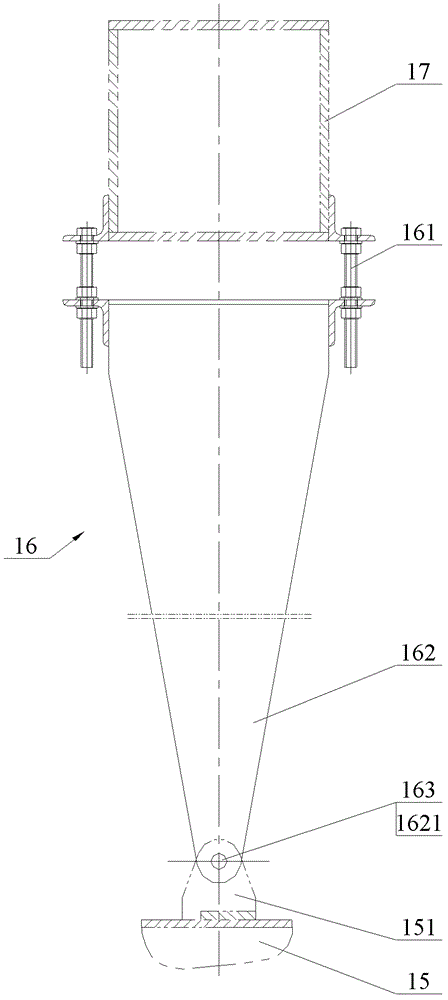

[0040] The core of the present invention is to provide a hanger device for hoisting the door-shaped sealing device on the support beam of the trolley, which can effectively use the screw thread to adjust the overall length to meet the assembly requirements of the door-shaped sealing device. The advantages of operation; at the same time, it provides an effective guarantee for improving operation safety.

[0041] Without loss of generality, this embodiment will be described in detail below in conjunction with the accompanying drawings.

[0042] The orientation words involved in this article, such as upper and lower, are defined based on the use status of the annular cooler. It should be understood that the use of the above orientation words, such as upper and lower, does not limit the scope of protection claimed in this application.

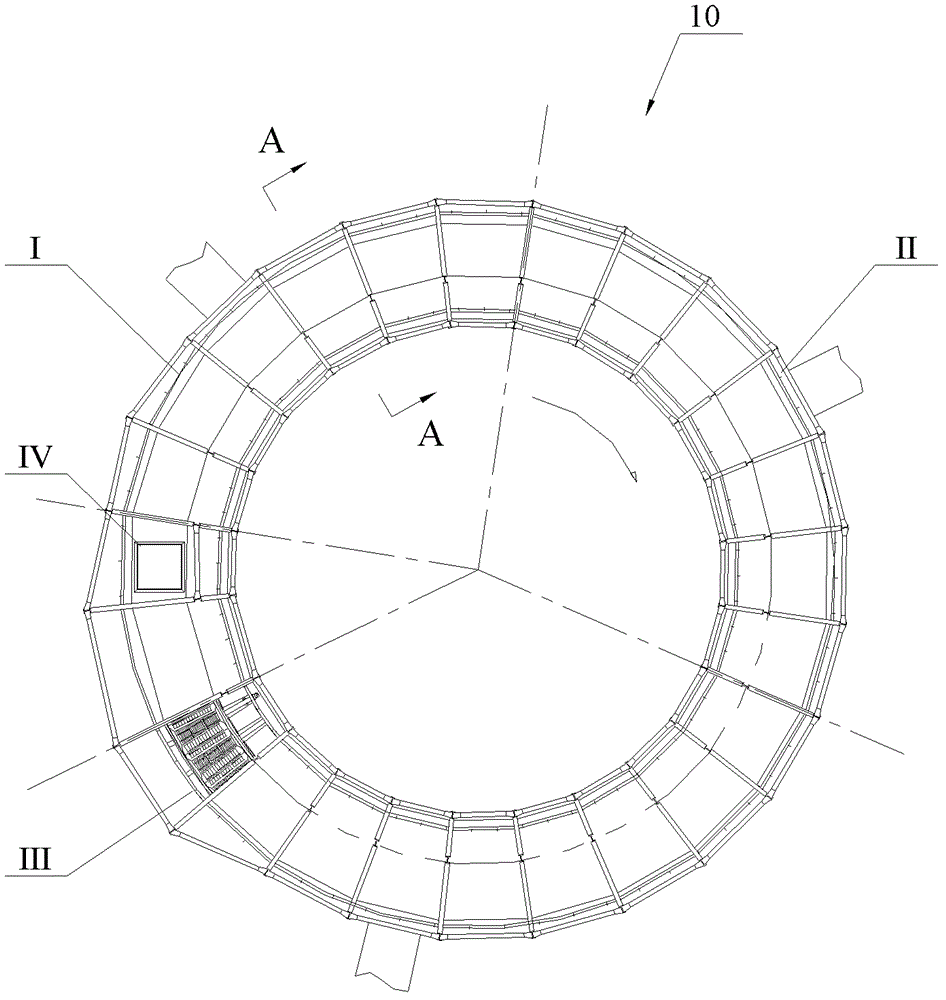

[0043] The annular cooler described in this embodiment is roughly divided into high-temperature zone I, medium-temperature zone II, low-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com