Household floor gas furnace

A floor-to-ceiling furnace and gas technology, applied in household heating, household heating, household appliances, etc., can solve the problems of small heating area, poor safety, low thermal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

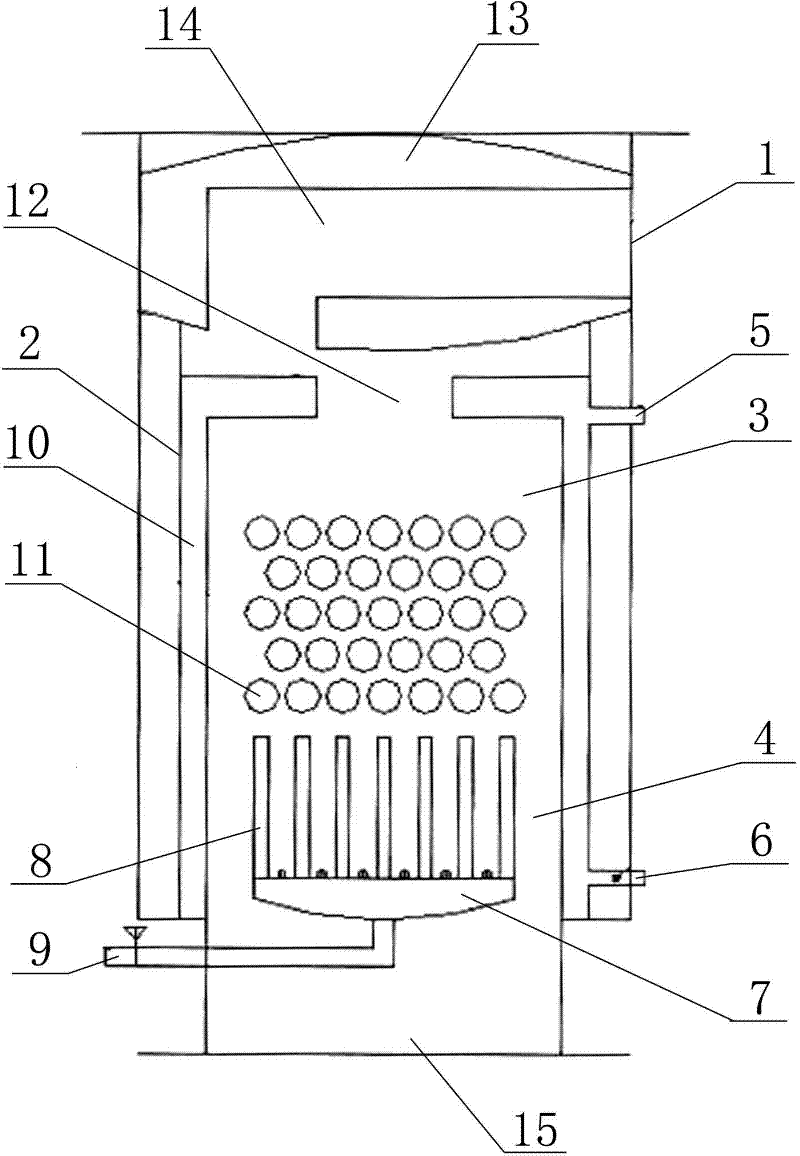

[0011] A household gas-fired floor-standing furnace includes a furnace shell 1, a furnace body 2 disposed in the furnace shell 1, a furnace 3 disposed in the furnace body 2, and a combustion chamber 4 disposed below the furnace 3; A water outlet 5 and a water return port 6; a burner 7 is installed in the combustion chamber 4; a combustion grate 8 is installed on the top of the burner 7, and a gas inlet 9 is provided at the bottom of the burner 7; There is a water jacket 10; a layered tube heat exchanger composed of a heat exchange tube array is installed in the furnace 3, and the heat exchange tube array includes several heat exchange tubes 11 arranged horizontally and fixed in the furnace 3 and parallel to each other; The pipes 11 are all in communication with the water jacket 10; the top of the furnace 3 has an exhaust port 12; the upper end of the furnace body 2 is fixed with a waste heat absorption water tank 13, and a waste heat recovery pipe 14 is installed in the waste h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com