Method for extracting 1-deoxynojirimycin and resveratrol from mulberry leaf

A technology of resveratrol and mulberry leaves, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of easy loss of 1-deoxynojirimycin and resveratrol, high production conditions, Problems such as long flocculation and sedimentation time are achieved to alleviate the large demand, ensure follow-up resources, and make planting easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

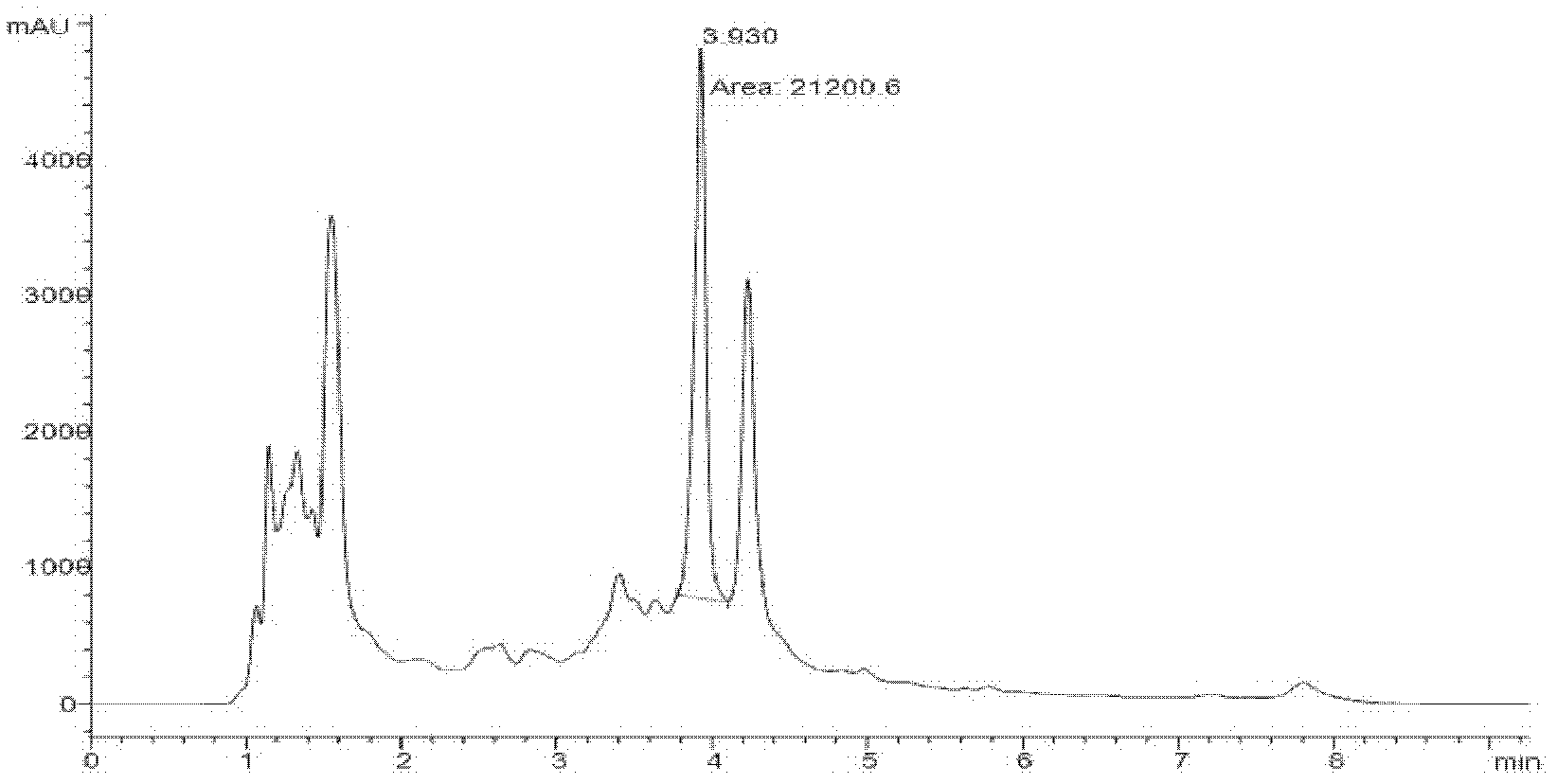

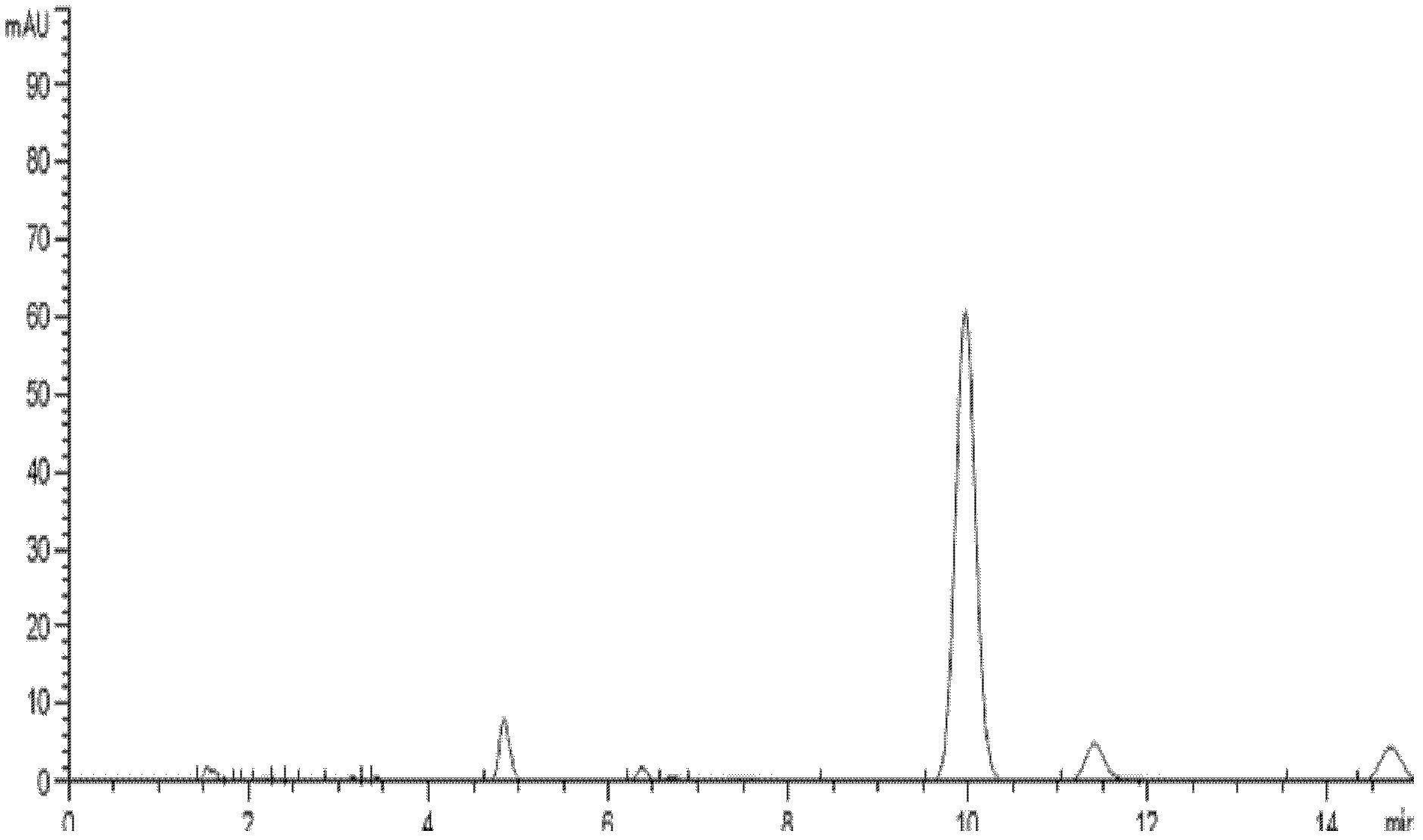

Embodiment 1

[0036] Crush and dry 100kg of mulberry leaves, add 700L of water, heat and reflux at 86°C for 2 hours, filter the extract twice through three layers of gauze, filter through a ceramic membrane, concentrate under reduced pressure to 100L, add 50kg of granular activated carbon for decolorization for 30min, and the solution after decolorization Use KLFC-150 macroporous adsorption resin for separation, first use pure water to elute impurities, then use 30% ethanol to elute, collect ethanol eluate, concentrate under reduced pressure to 50L, slowly lower the temperature to room temperature for 24h to obtain 205g DNJ samples.

[0037] The residue after water extraction of mulberry leaves was extracted with 500L of 70% ethanol, heated and refluxed at 80°C for 2h, filtered twice with three layers of gauze, filtered with a ceramic membrane, concentrated under reduced pressure to 60L (no ethanol smell), and then the concentrated solution was divided with 150L ethyl acetate. Extract three...

Embodiment 2

[0040] Crush and dry 200kg of mulberry leaves, add 1600L of water, heat and reflux at 86°C for 2 hours, and filter the extract twice through three layers of gauze and ceramic membrane. Use KLFC-150 macroporous adsorption resin for separation, first use pure water to elute impurities, then use 30% ethanol to elute, collect ethanol eluate, concentrate under reduced pressure to 90L, slowly lower the temperature to room temperature for 24 hours to crystallize, and obtain 421g DNJ samples.

[0041] The residue after water extraction of mulberry leaves was extracted with 1150L of 70% ethanol, heated and refluxed at 80°C for 2h, filtered twice with three layers of gauze, filtered with a ceramic membrane, concentrated under reduced pressure to 110L (no ethanol smell), and then the concentrated solution was divided with 170L ethyl acetate. Extract three times, combine the ethyl acetate layer and concentrate to 95L, add 8kg granular activated carbon to decolorize for 30min, after decolo...

Embodiment 3

[0043] Crush and dry 400kg of mulberry leaves, add 3400L of water, heat and reflux at 86°C for extraction for 2 hours, filter the extract twice through three layers of gauze and ceramic membrane, concentrate under reduced pressure to 350L, add 80kg of granular activated carbon for decolorization for 30min, and the solution after decolorization Use KLFC-150 macroporous adsorption resin for separation, first use pure water to elute impurities, then use 30% ethanol to elute, collect ethanol eluate, concentrate under reduced pressure to 160L, slowly lower the temperature to room temperature for 24 hours to obtain 830g DNJ samples.

[0044] The residue after water extraction of mulberry leaves was extracted with 2500L of 70% ethanol, heated and refluxed at 80°C for 2h, filtered twice with three layers of gauze, filtered with a ceramic membrane, concentrated under reduced pressure to 60L (no ethanol smell), and then the concentrated solution was divided with 150L ethyl acetate. Extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com