Plunger type injection molding device

A technology of plunger type and transmission device is applied in the field of plunger type injection molding device, which can solve the problems of low screw life and uneven temperature of plasticized raw materials, and achieve the effects of reducing equipment manufacturing costs, not easy to bend, and small torsion force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

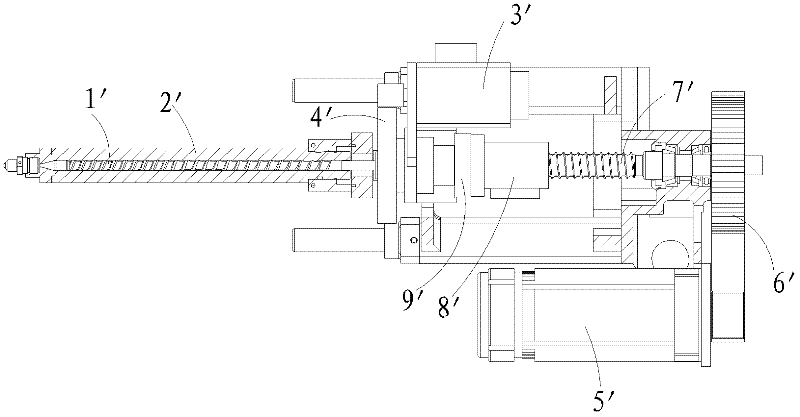

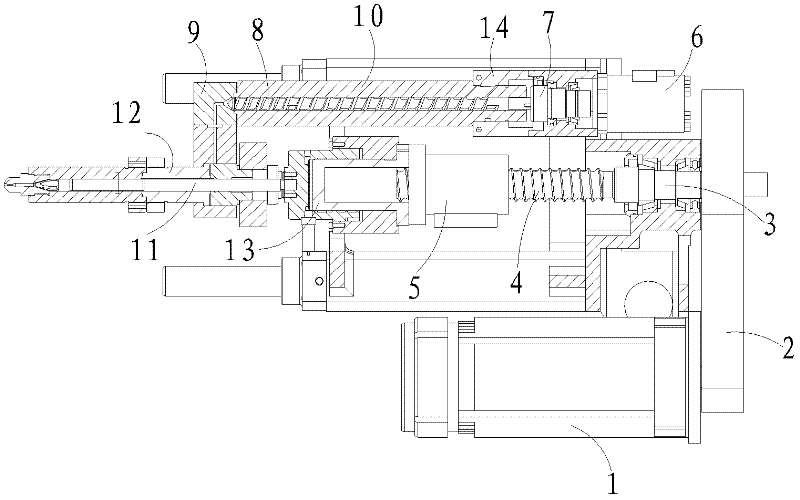

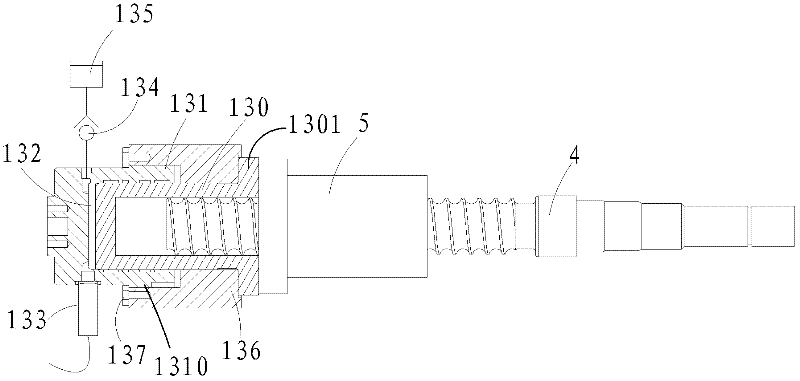

[0018] see Figure 2 to Figure 4 As shown, the embodiments of the present invention will be described in detail.

[0019] like figure 2 , taking the left direction in the figure as the front end, and the right direction as the tail (rear) end. The present invention is a plunger type injection molding device, which includes a servo motor 1, a transmission device 2, a transmission member 3, a ball screw 4, a ball nut 5, the servo motor 1 is connected to the transmission through the transmission device 2 Part 3, the transmission part 3 is connected to the ball screw 4, the ball screw 4 is connected to the ball nut 5, and it also includes a hydraulic motor 6, a transmission shaft 7, a plasticizing screw 8, a diversion Plate 9, a sleeve 10 set on the plasticizing screw, a plunger rod 11, a discharge barrel 12 set on the plunger rod 11, a pressure detection structure 13, the hydraulic motor 6 is connected to the Transmission shaft 7, the other end of the transmission shaft 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com