Foam plane-making machine capable of feeding air at two ends

A sheet and foam technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problems of reducing product quality, energy waste, low steam utilization rate, etc., to improve work efficiency, reduce consumption, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0038] Example.

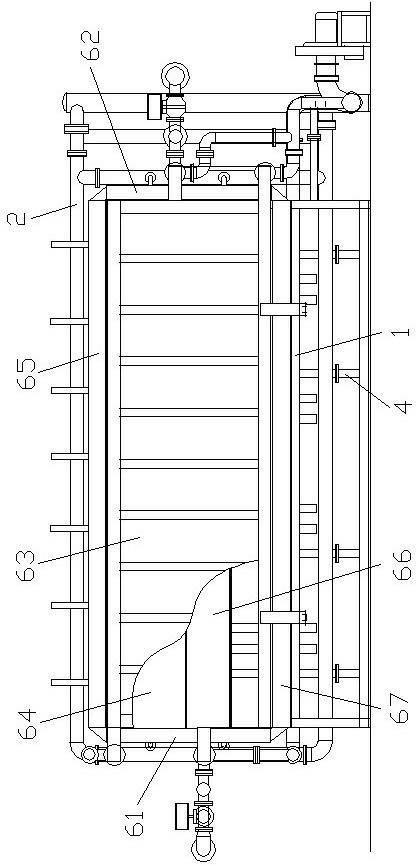

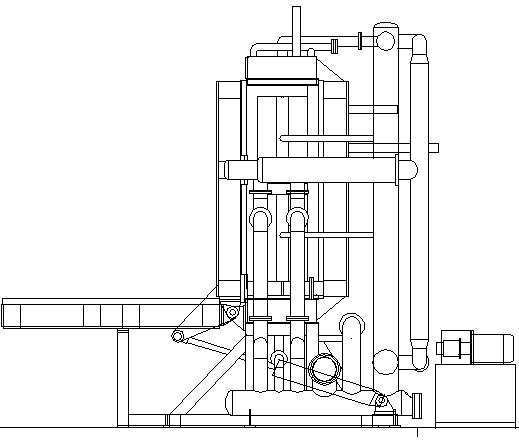

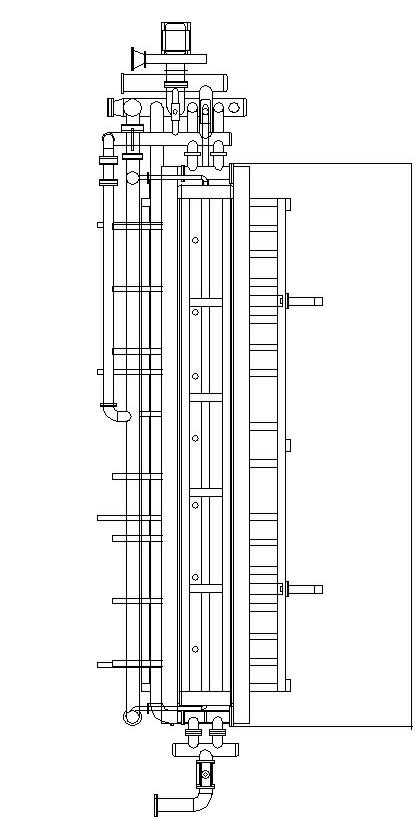

[0039] see Figure 1 to Figure 17 , the two-head air intake foam board machine in this embodiment includes a frame 1, a pipeline device 2, four sets of lifting devices 4, a left template 61, a right template 62, a front template 63, a rear template 64, a top template 65, an air Frame bottom formwork 66 and base plate 67, wherein, the number of sets of lifting device 4 among the present invention is at least one set of lifting device 4, the number of sets of this lifting device 4 can be set according to actual needs, and under normal circumstances, the quantity of this lifting device 4 can be Between 2-8 sets.

[0040] Left formwork 61 among the present embodiment, right formwork 62, front formwor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com