Assembly system of integrated gearbox

A technology of assembly system and gear box, applied in assembly machines, lifting devices, workpiece clamping devices, etc., can solve the problems of high labor intensity, inability to guarantee assembly accuracy and quality, and unfavorable operation, so as to improve assembly quality and efficiency. , Eliminate the difficulty of subsequent assembly and the effect of repeatedly moving the ring gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

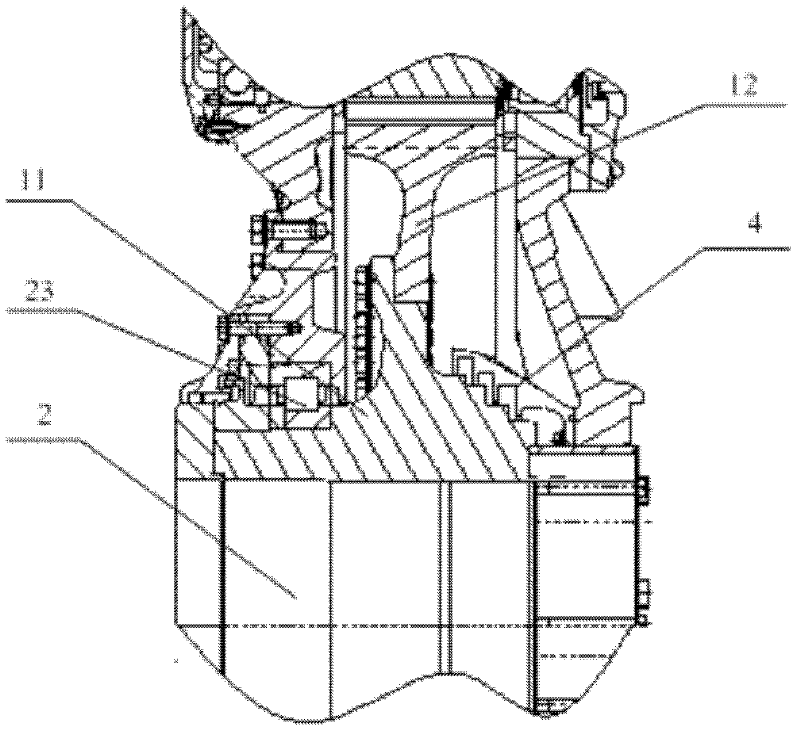

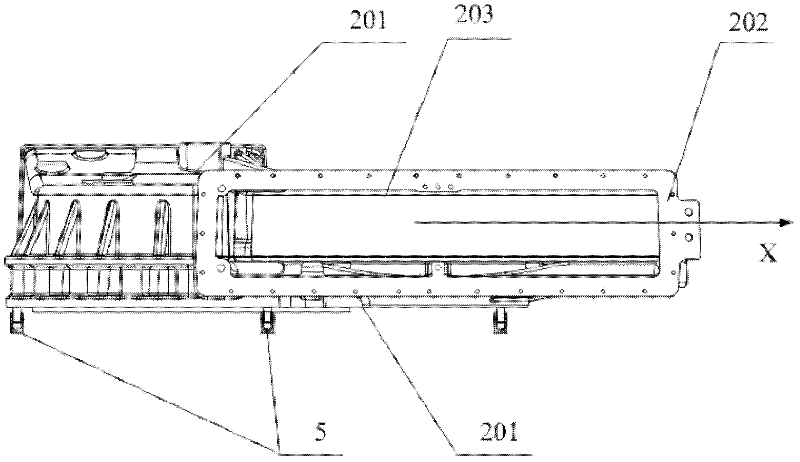

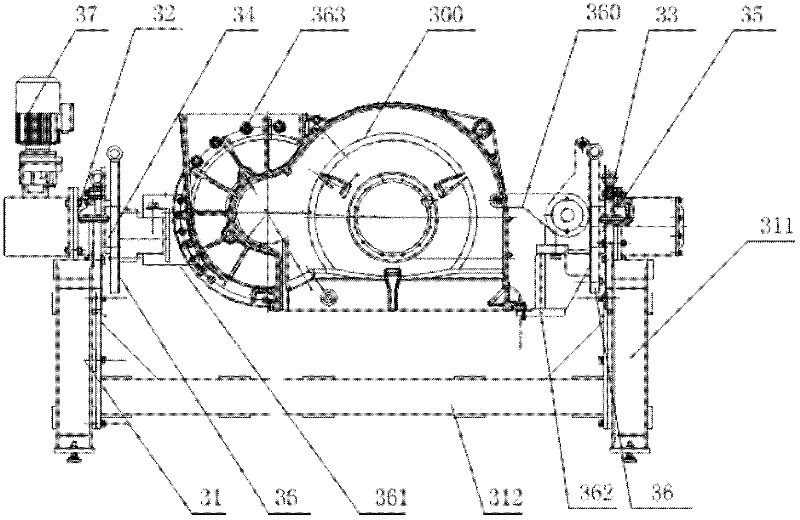

[0032] image 3 It is a structural schematic diagram of the case turning device in an embodiment of the integrated gearbox assembly system of the present invention. Figure 4 It is a front view of the hoisting device in an embodiment of the integrated gearbox assembly system of the present invention. Please refer to image 3 and Figure 4 , The integrated gear box assembly system provided in this embodiment includes a box turning device and a lifting device. Wherein, the box turning device includes a bracket 31, on the bracket 31, a first bearing seat 32 and a second bearing seat 33 are oppositely arranged along the horizontal direction, the first bearing seat 32 is provided with a drive shaft 34, and the second bearing seat 33 is provided with A driven shaft 35 is provided, and the ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com