Roller processing machine

A technology for processing machine tools and rolls, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of high technical requirements, difficulty in ensuring processing accuracy, and low work efficiency, and achieve accurate indexing and easy processing accuracy Guaranteed, efficient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

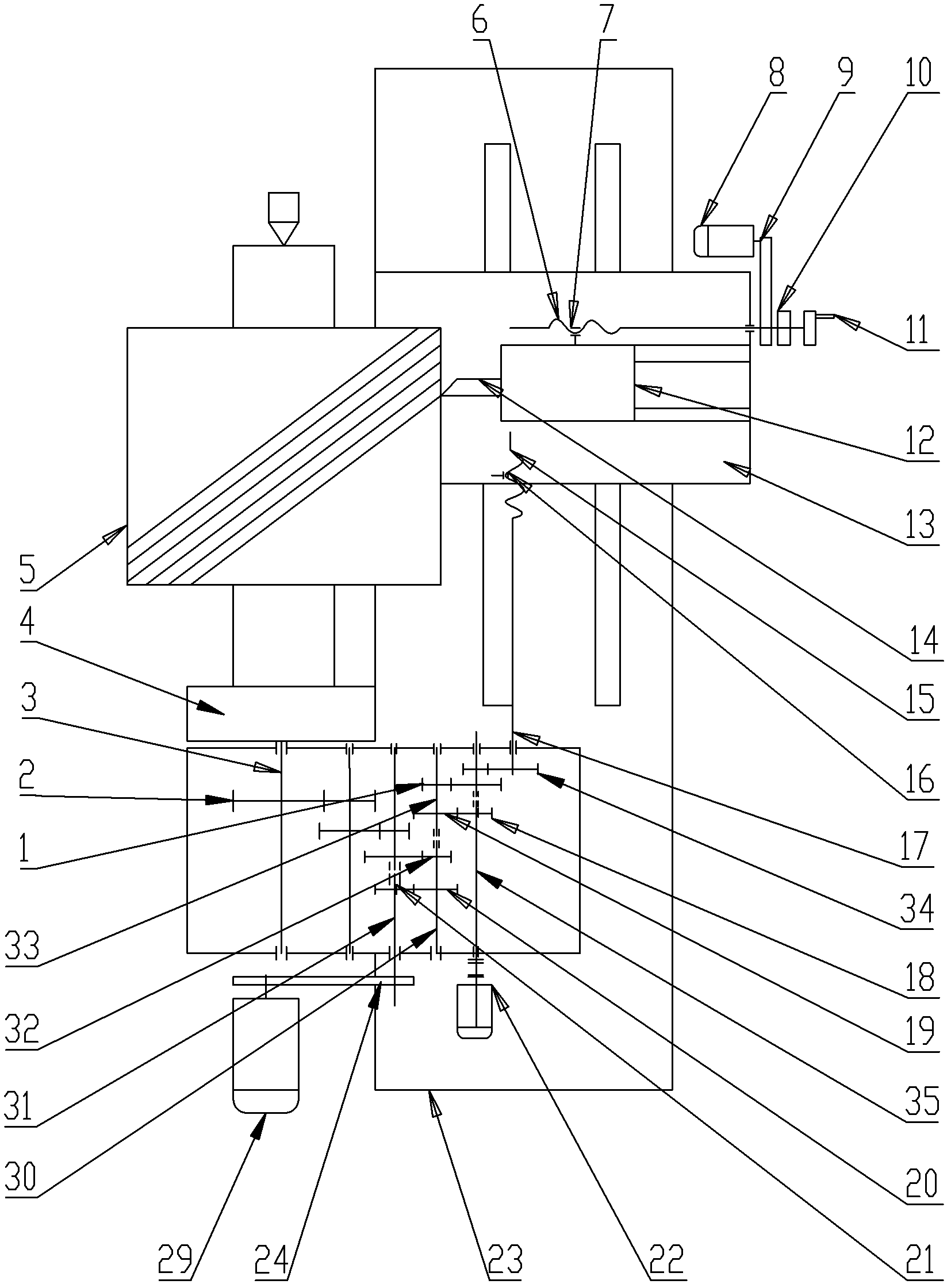

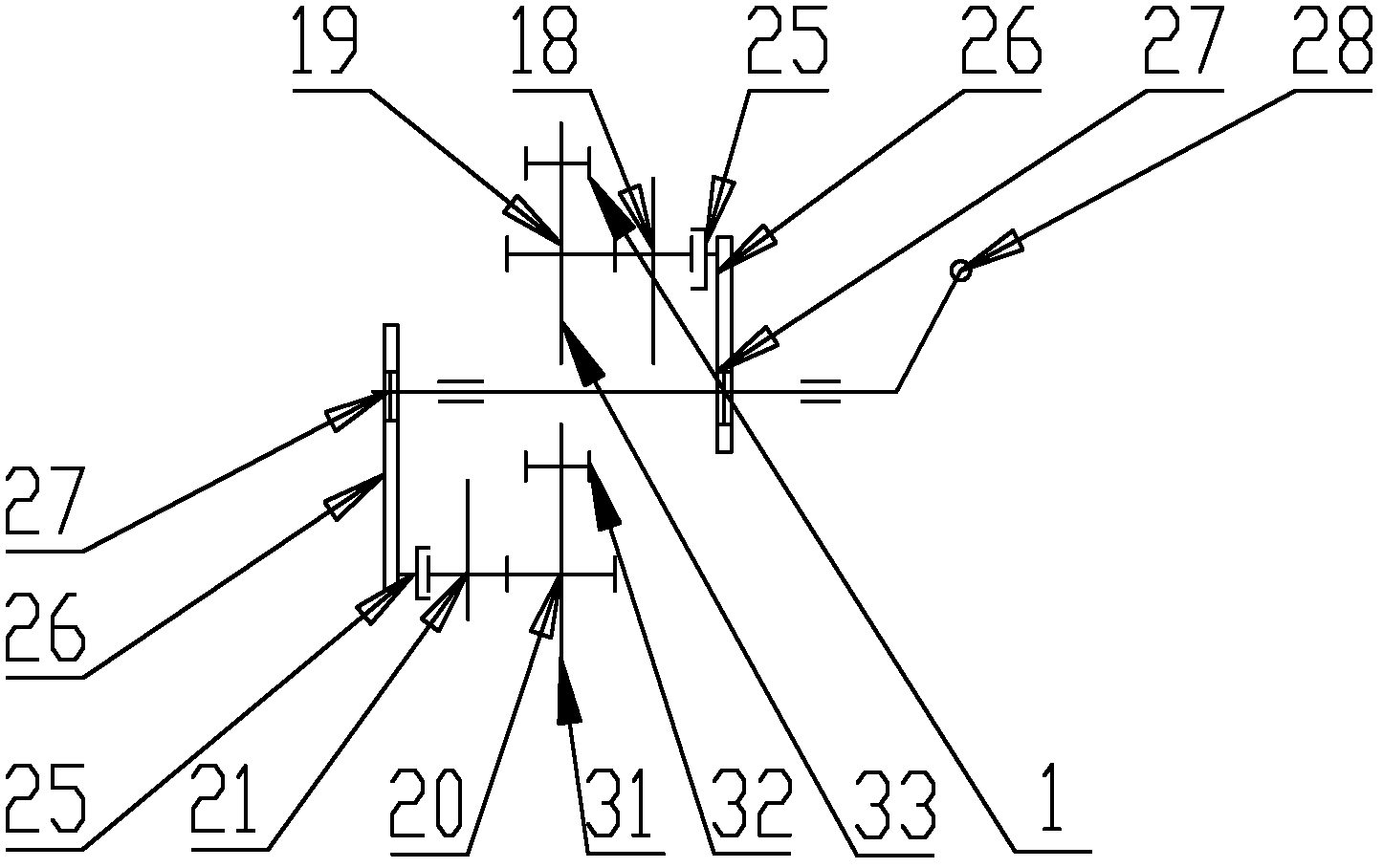

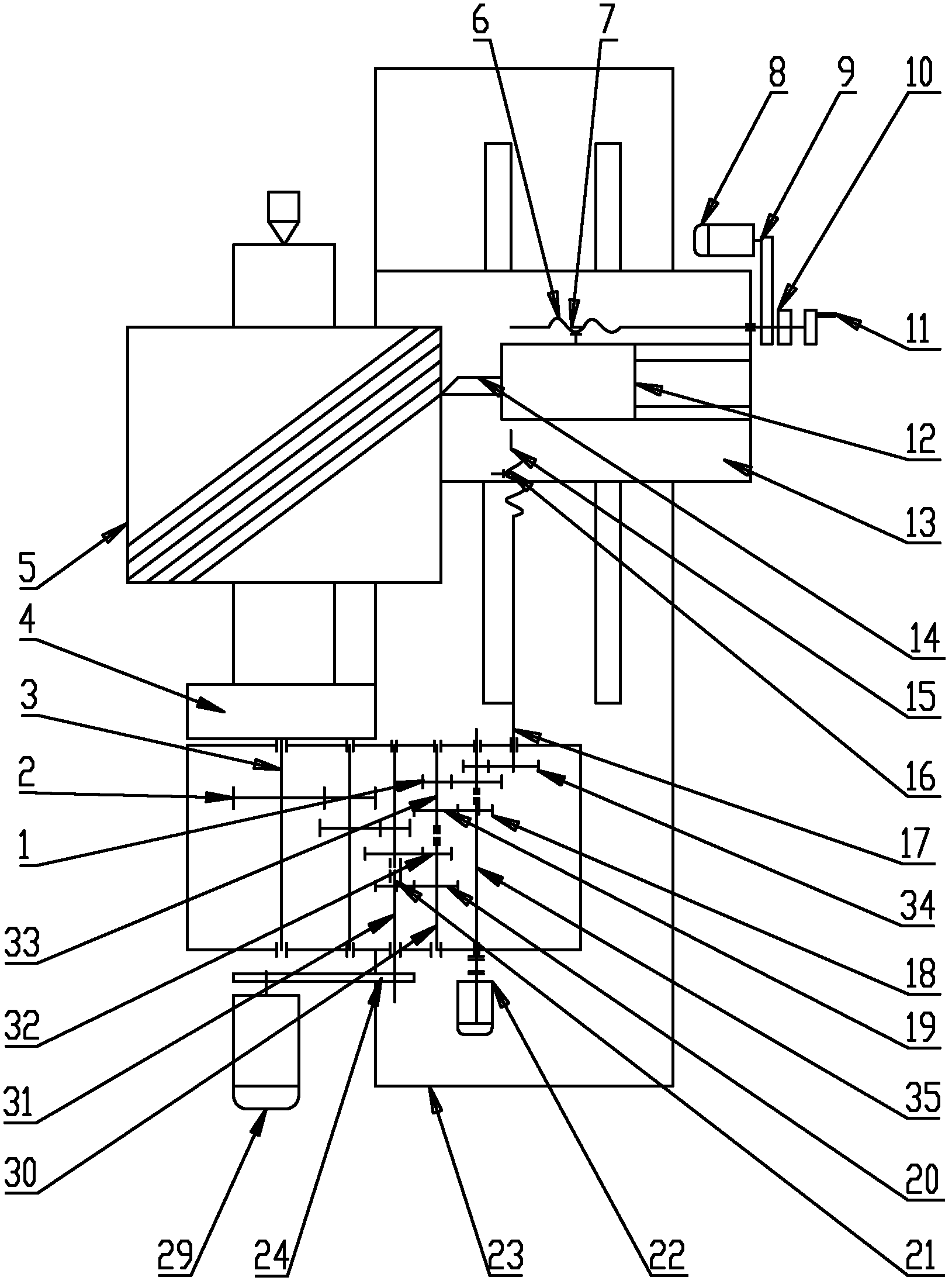

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0016] See Figure 1 ~ Figure 2 , a roll processing machine tool, including a turning tool radial feed mechanism and a gear box, the first input shaft 31, the second input shaft 35, the first output shaft 3 and the second output shaft parallel to each other are installed in the gear box Shaft 17 and coaxially arranged first transition shaft 30 and second transition shaft 33; said first transition shaft 30 is equipped with input gear A20 and transmission gear A32, and said transmission gear A32 drives the first transition shaft through the first gear transmission mechanism A gear 2, the first gear 2 is installed on the first output shaft 3, the workpiece chuck 4 is connected on the first output shaft 3; the input gear B19 and the second transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com