Clutch transmission device of self-propelled mower

A clutch transmission, lawn mower technology, applied in harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of large clutch connection friction loss, large clutch noise, incomplete separation, etc., and achieve low clutch noise and friction. Small loss, novel and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

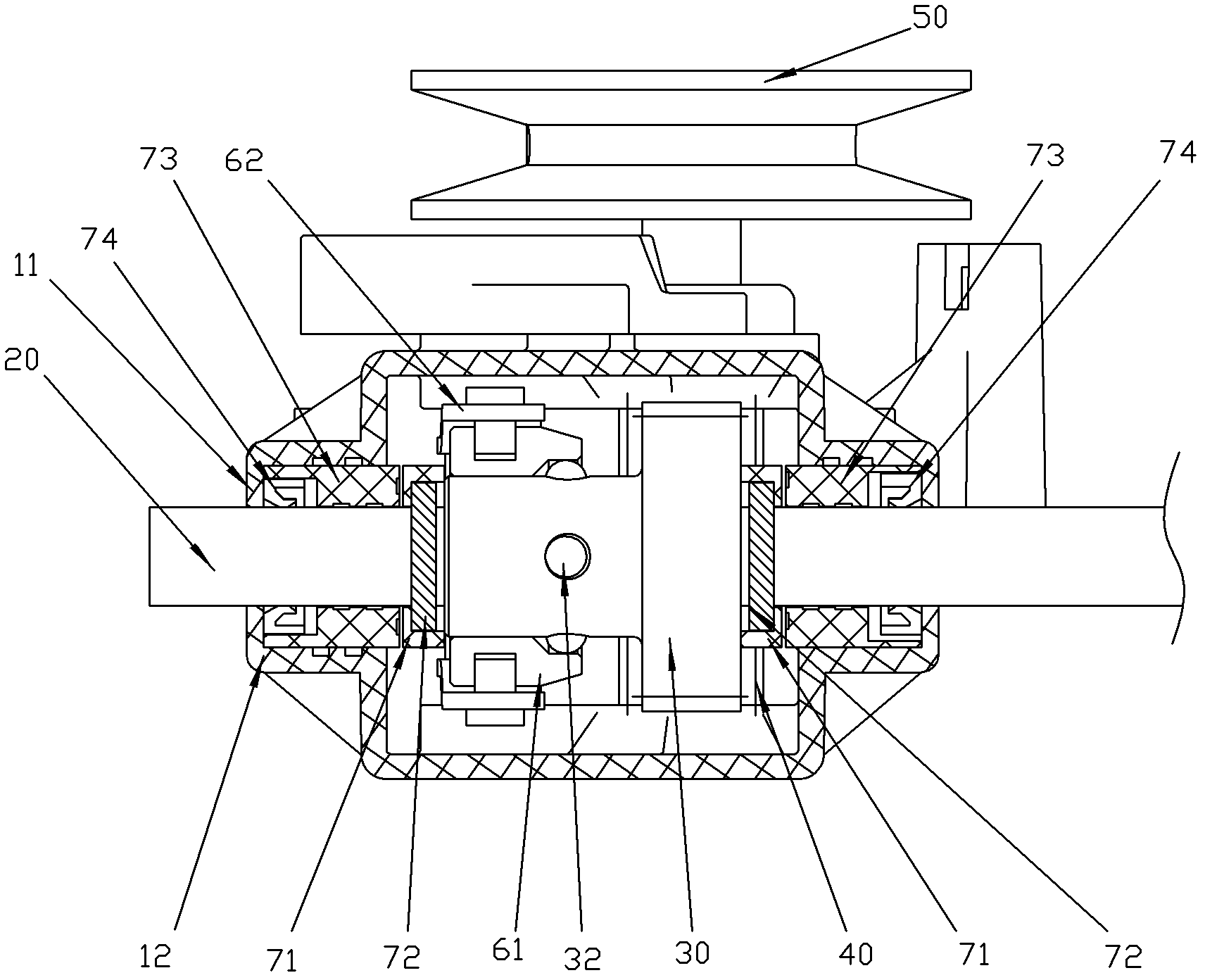

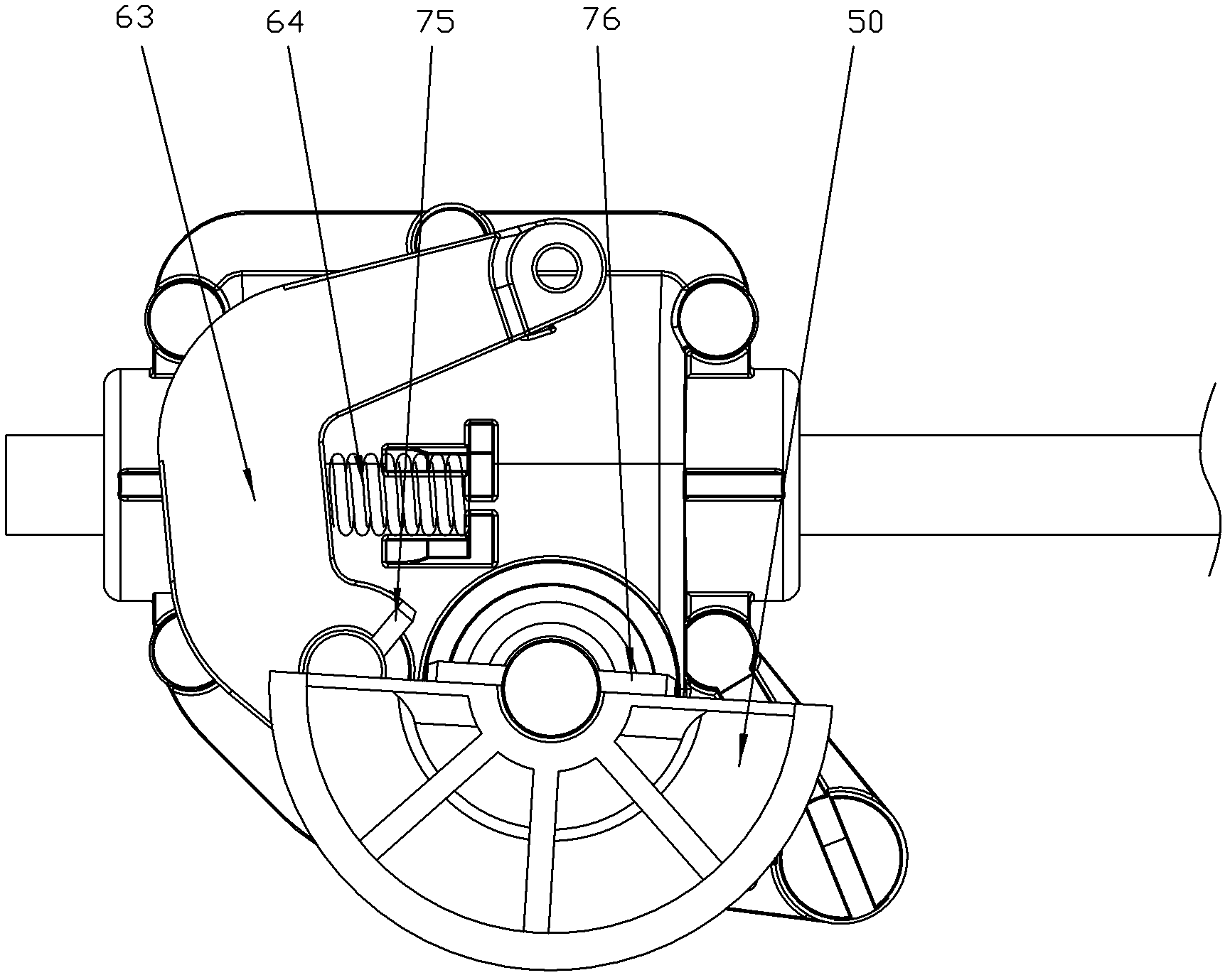

[0028] refer to figure 1 , figure 2 and image 3 , a clutch transmission device of a self-propelled lawnmower of the present invention includes a housing assembly, a shaft 20, a worm gear assembly 30, a worm 40, a sliding sleeve 61, a swing rod 62, and a rocker arm 63, a return spring 64 and a clutch pull wire.

[0029] The shell assembly is composed of an upper shell 11 and a lower shell 12, and the upper shell 11 and the lower shell 12 are mutually covered to form an accommodating space.

[0030] The shaft rod 20 extends through the above-mentioned housing assembly, and its two ends extend outside the above-mentioned housing assembly. The shaft rod 20 is provided with four ball sockets 21 in its part located in the above-mentioned accommodating space; the shaft rod 20 Both ends are equipped with lubricating components and placed on the fixed plates on both sides of the lawn mower, and a rod end gear is provided at each end, which meshes with the gear in the rear wheel of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com