Shaft seal for a turbomachine

A shaft seal and seal technology, applied in the field of shaft seals, can solve the problems of high cost and high nitrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

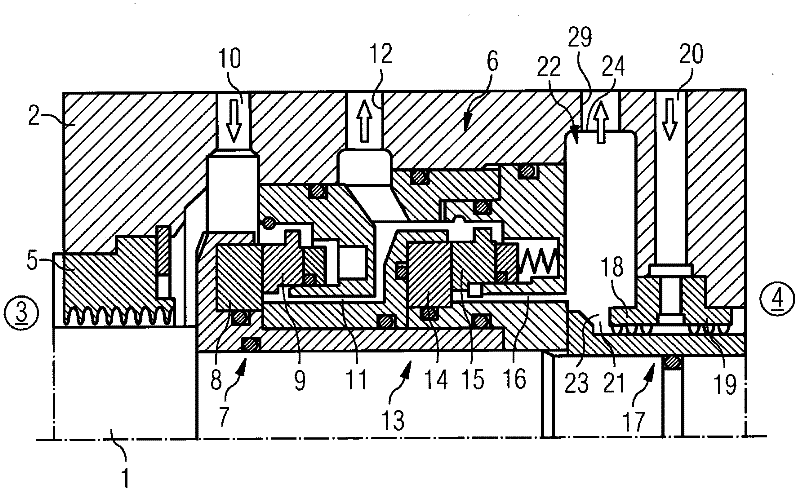

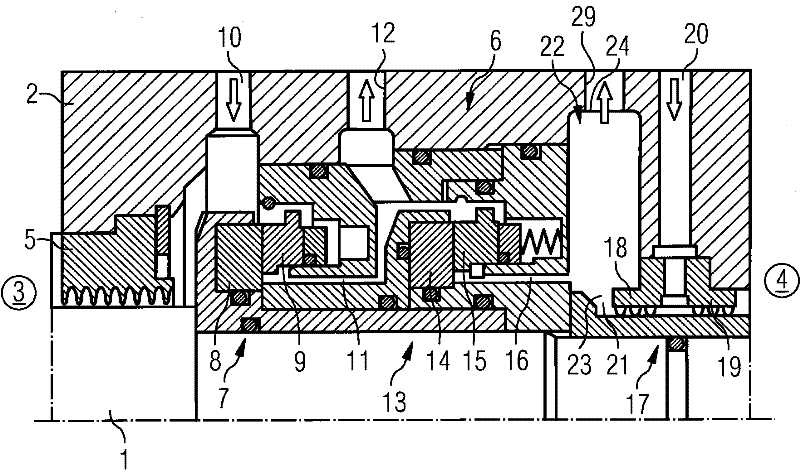

[0014] as from figure 1 and figure 2 As can be seen in the figure, the turbocompressor has a turbocompressor shaft 1 and a turbocompressor housing 2 , wherein the illustrated longitudinal end of the turbocompressor shaft 1 passes through the turbocompressor housing 2 .

[0015] The interior of the turbocompressor is formed by the process side 3 , whereas outside the turbocompressor there is an atmosphere 4 . On the process side, a higher than atmospheric pressure exists in the turbocompressor during operation, so that the turbocompressor shaft 1 can be sealed against the turbocompressor housing 2 from the process side 3 towards the atmosphere 4 . The sealing is achieved by means of a labyrinth seal 5 and a gas-lubricated slide ring seal 6, wherein the labyrinth seal 5 is arranged on the process side and the slide ring seal 6 is installed between the labyrinth seal 5 and the Atmosphere between 4. The gas-lubricated sliding ring seal 6 has a main seal 7 arranged directly dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com