Fireproof power cable with high volume used in rail transit

A technology for rail transit and power cables, applied in the field of power cables, can solve the problems of poor fire resistance, easy to fall off, and it is difficult to ensure the safe use of power cables, so as to achieve good fire resistance and improve transmission capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

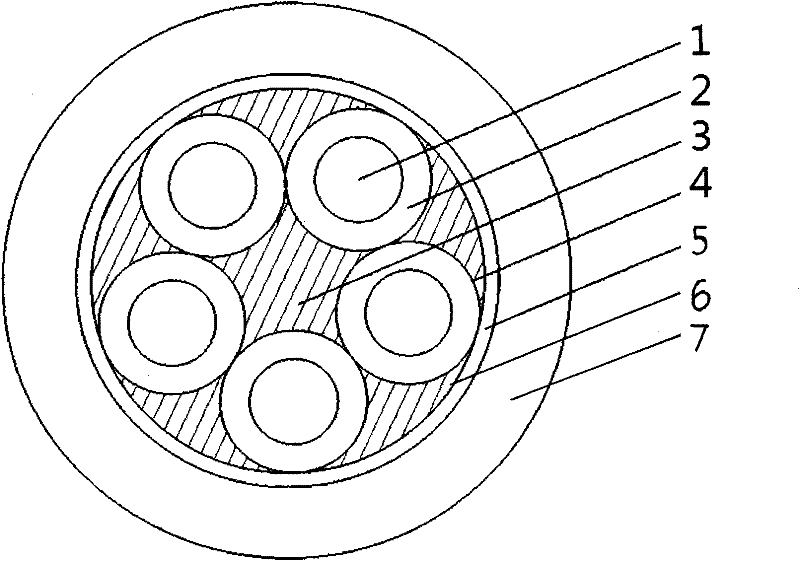

[0010] refer to figure 1 , the conductor 1 is coated with a ceramic silicon rubber insulating layer 2 to make a wire 4 . Several conductors 4 and flame-retardant glass fiber ropes 3 are twisted together to form a cable core 6, and the outside of the cable core 6 is coated with a flame-retardant glass fiber tape layer 5 and an outer sheath 7 made of halogen-free and low-smoke sheath material. , namely make the present invention of a kind of structure.

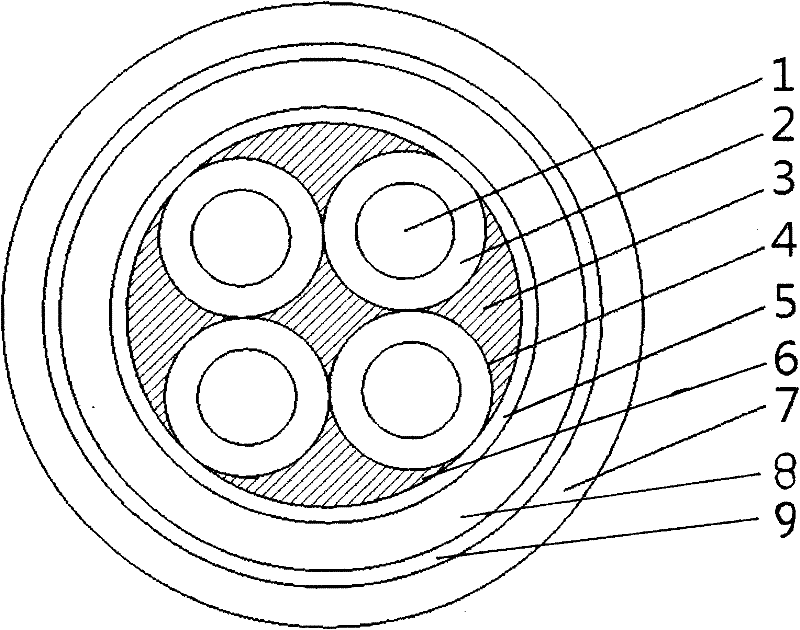

[0011] refer to figure 2 , the conductor 1 is coated with a ceramic silicon rubber insulating layer 2 to make a wire 4 . Several wires 4 are twisted together with flame-retardant glass fiber rope 3 to form a cable core 6, and the outside of the cable core 6 is covered with a flame-retardant glass fiber tape layer 5, a silicone rubber inner lining layer 8, a steel tape armor layer 9 and The outer sheath 7 made of halogen-free low-smoke sheath material is another structure of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com