Pressure plate parallelism detection device of clutch cover assembly

A clutch cover and detection device technology, applied in the direction of angle/taper measurement, etc., can solve the problems of inability to ensure the accurate size of products detected, high labor intensity of employees, slow detection speed, etc., so as to shorten the detection time of parallelism and improve the Productivity and ease of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

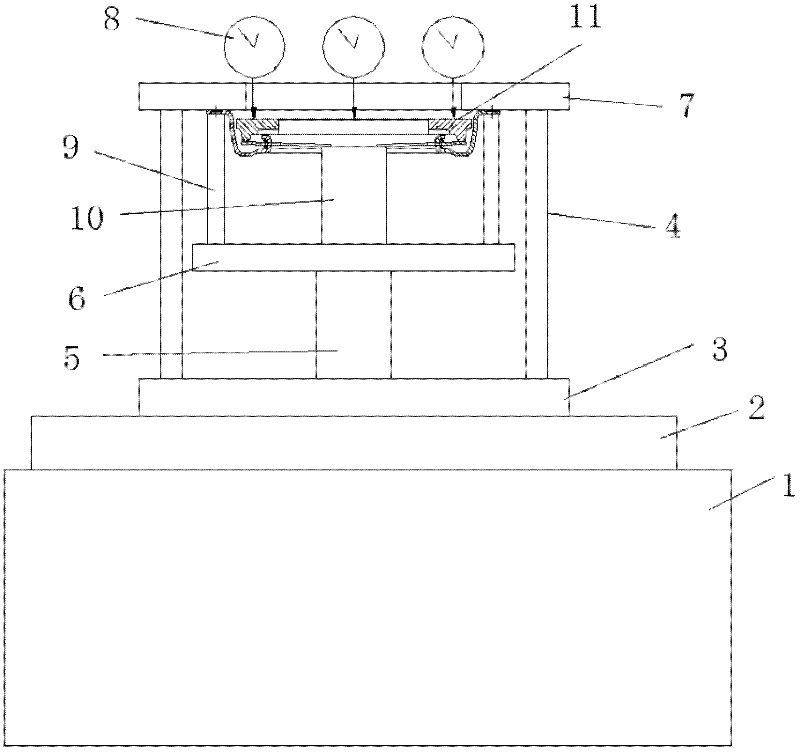

[0011] Such as figure 1 A pressure plate parallelism detection device for a clutch cover assembly is shown, including a hydraulic press 1, a base 2, and a base plate 3 arranged on the base 2. The base plate 3 is provided with a plurality of columns 4, and the plurality of columns 4 are supported with On the upper tray 7, the upper tray 7 is provided with a plurality of dial indicators 8, the bottom plate 3 is provided with a piston 5 controlled by the hydraulic machine 1, the top of the piston 5 is provided with a lower tray 6, and the upper end surface of the lower tray 6 A plurality of positioning pins 9 are provided, and a marking block 10 is provided in the middle of the upper end surface of the lower tray 6. The marking block 10 and the plurality of positioning pins 9 jointly support the clutch cover assembly, and the end of the rod body of the dial indicator 8 passes through the upper tray. 7 down. Column 4 is three. The dial gauge 8 is three.

[0012] When working, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com