Device for simultaneously ensuring uniform load of transmission with double intermediate shafts and left and right concentricity of synchronizer

A technology of double countershafts and transmissions, applied in transmissions, gear transmissions, belts/chains/gears, etc., which can solve the problems of gearbox synchronizer loss, frequent replacement and maintenance, and user inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

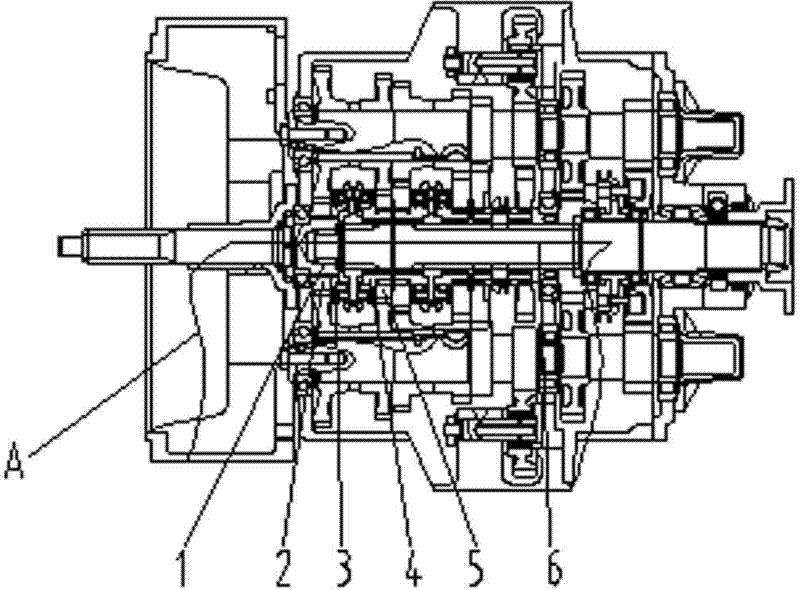

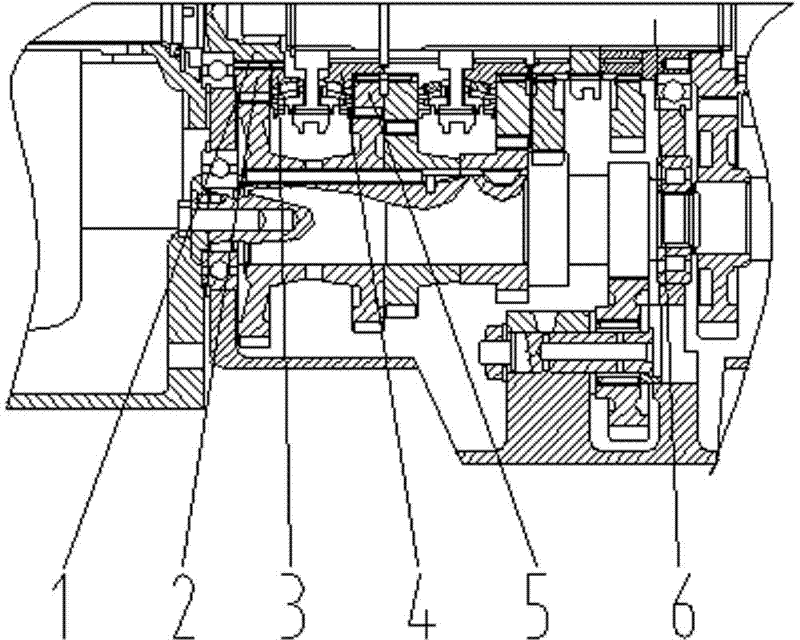

[0012] see figure 1 , a double countershaft transmission that ensures both load balance and synchronizer left and right concentricity, including input shaft 1, constant meshing gear 2, engaging teeth 3 of constant meshing gears, coupling teeth 4 of output shaft gears for each gear, and output gears for each gear The shaft gear 5 and the output shaft 6, the output shaft gear 5 of each gear floats on the engaging teeth 4 of the output shaft gears of each gear through the spline clearance, and the engaging teeth 4 of the output shaft gears of each gear are centered on the output shaft 6 through needle bearings On the one hand, the coaxial feature between the cone ring of the synchronizer and the two conical surfaces of the left and right engaging teeth is guaranteed. The constant meshing gear 2 floats on the input shaft 1 through the spline clearance, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com