Multifunctional inspection equipment of nuclear reactor pressure vessel nozzle

A technology for pressure vessels and inspection equipment, applied in the field of video inspection equipment and ultrasound, which can solve the problems of ineffective scanning of weld seams, limited inspection range, large volume, etc., to achieve multi-functional inspection, ensure accuracy and reliability, Comprehensive effect of ultrasound scan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

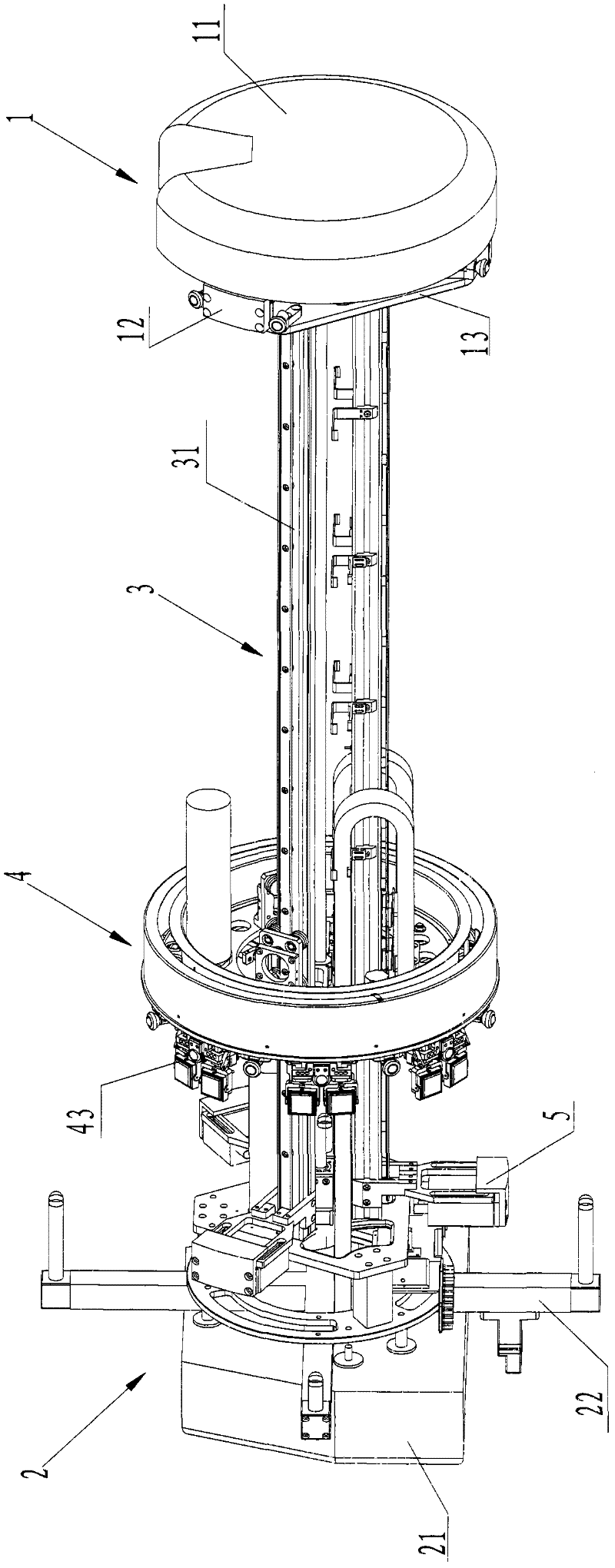

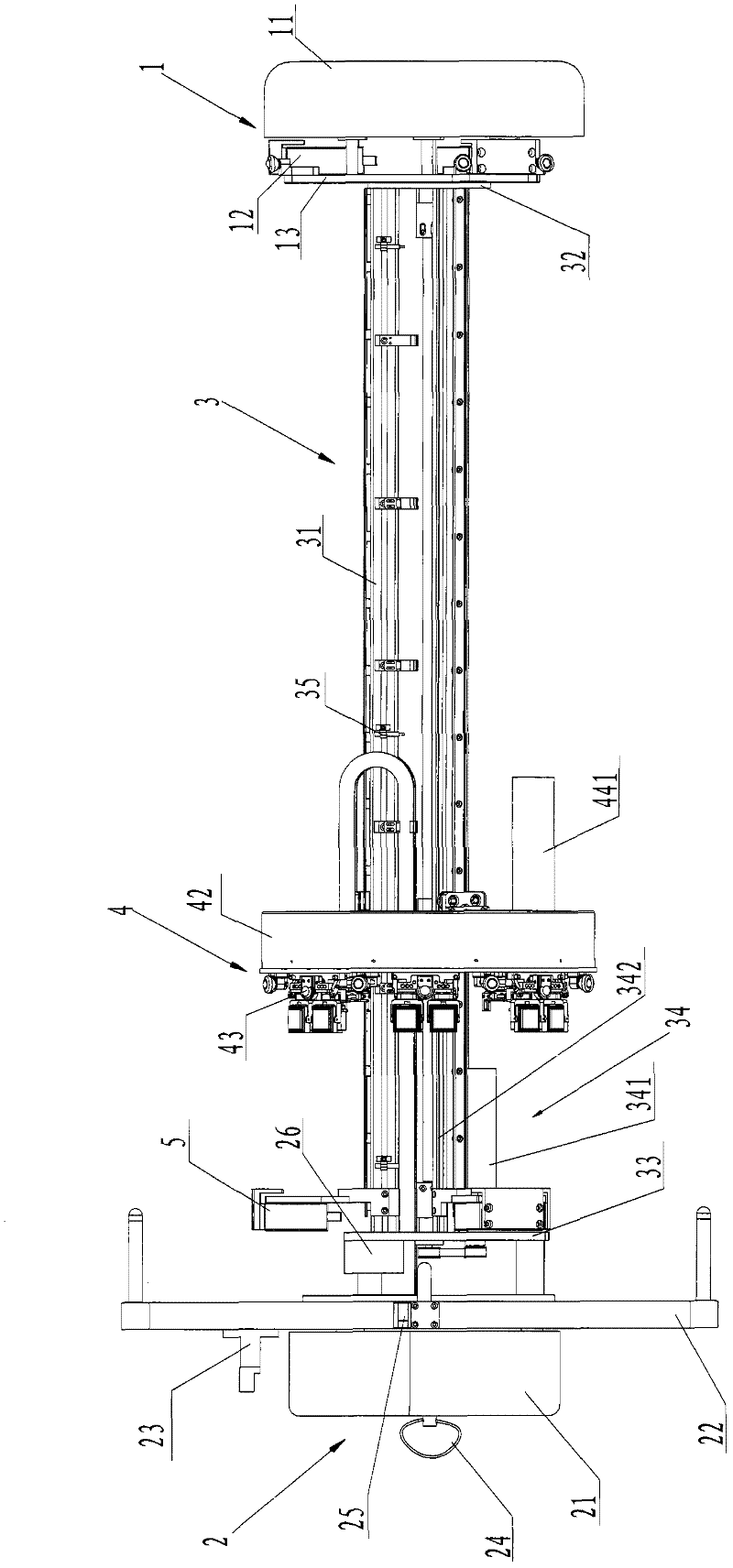

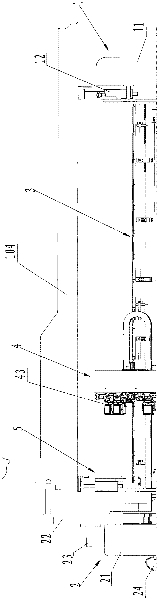

[0036] Below in conjunction with accompanying drawing, illustrate in detail the specific content of the preferred implementation of the ultrasonic inspection equipment of the present invention:

[0037] Since the inspection equipment of the present invention extends into the nozzle of the pressure vessel for detection, firstly define the view direction of the equipment in order to explain its structural features more clearly. We will call the end of the equipment first entering the nozzle For the front end, such as figure 1 , figure 2 On the right side shown, the other end where the equipment is finally positioned on the inner wall of the pressure vessel cylinder is called the rear end, such as figure 1 , figure 2 shown on the left.

[0038] Figure 1 to Figure 3It shows the inspection equipment preferably implemented according to the present invention, which is mainly composed of a front support module 1, a rear support module 2, a guide rail assembly 3 detachably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com