Ink, ink cartridge and ink jet recording method

An inkjet and pigment technology, applied in the direction of copying/marking methods, inks, fibrous fillers, etc., can solve the problem of image image density reduction, etc., and achieve the effects of high image density, excellent evaporation stability, and excellent image density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

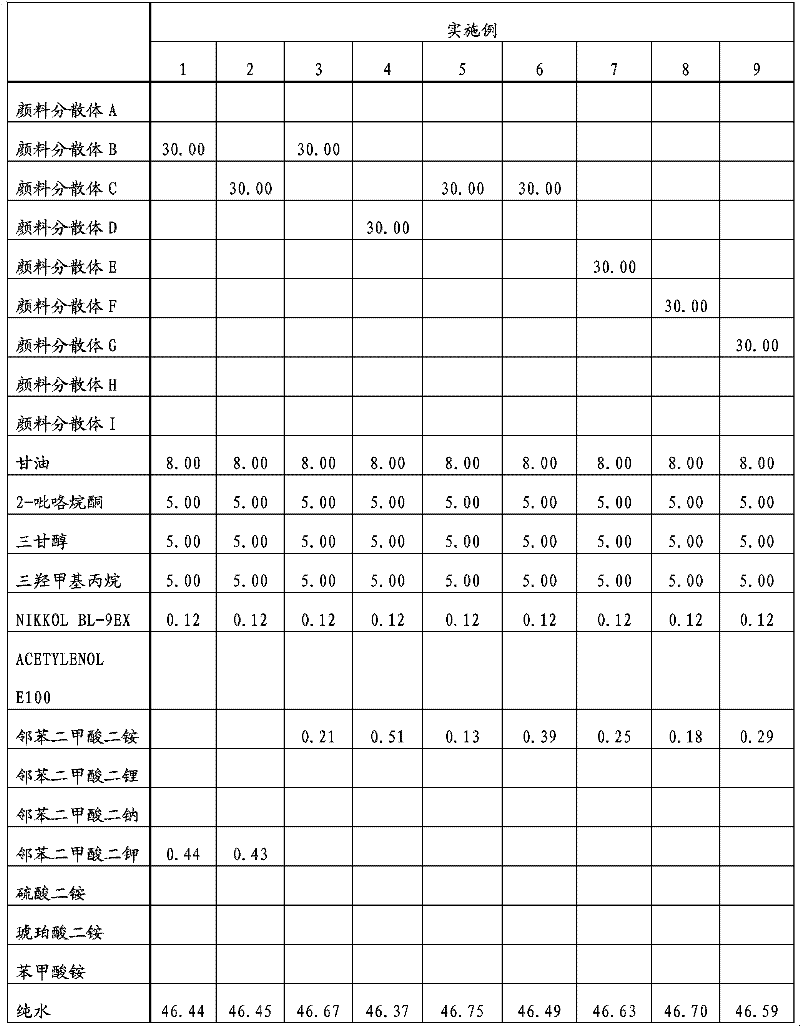

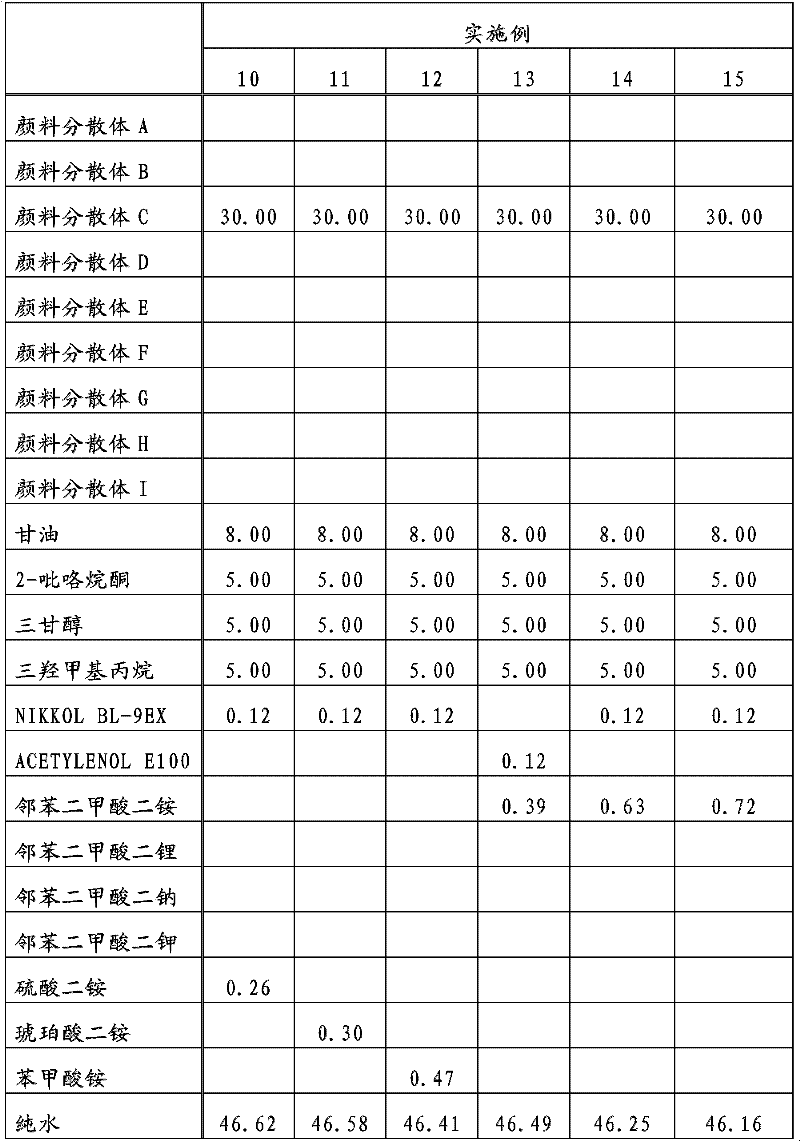

[0065] Hereinafter, the present invention will be described in more detail by the following examples and comparative examples. However, the present invention is not limited by the following examples as long as the gist of the present invention is not exceeded. Incidentally, all representations of "parts" or "parts" and "%" used below are based on mass unless specifically stated.

[0066] Preparation of Pigment Dispersion:

[0067] The amount of functional groups introduced in the pigment:

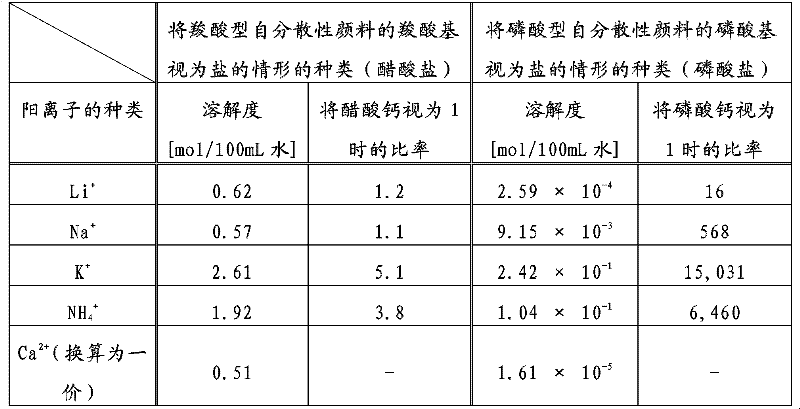

[0068] First, a method for measuring the amount of functional groups introduced into the pigment will be described. Liquid A was prepared by diluting the pigment dispersion liquid with pure water so that the content of the pigment to be measured was about 0.03%. Under the conditions of 5°C, 80,000rpm and 15 hours, the pigment dispersion liquid was ultracentrifuged to collect the supernatant liquid from which the bisphosphonic acid type self-dispersible pigment was removed, and the liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com