Method for preparing high-purity magnesium chloride hexahydrate from waste brine

A technology of magnesium chloride hexahydrate and brine, which is applied in the direction of magnesium chloride and magnesium halide, can solve the problems of high energy consumption, difficulty in guaranteeing sulfur content, etc., and achieve the effect of reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

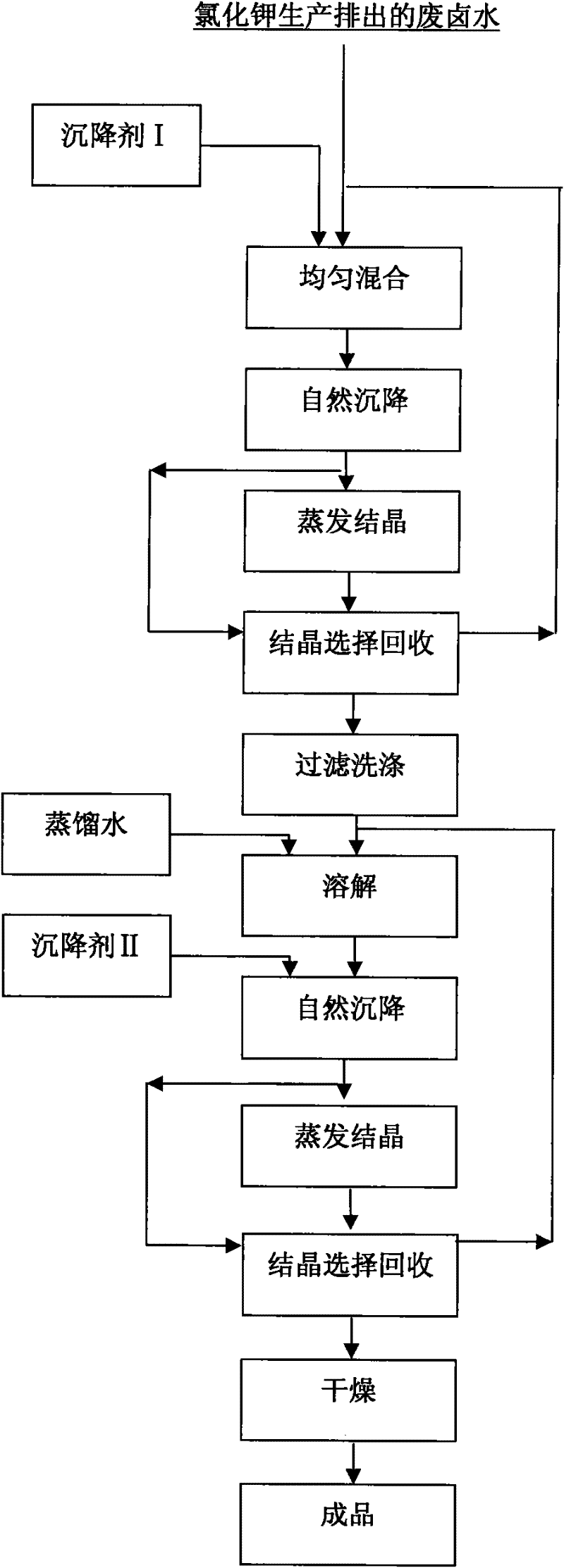

Method used

Image

Examples

example 2

[0047] Example two finished product component analysis results are as follows:

[0048] MgCl 2 46.60 KCl 0.002

[0049] SO 4 2- 4ppm B 3ppm

[0050] Fe 2ppm Ca 32ppm

[0051] Mn not detected Sr not detected

[0052] Br 2ppm Cr not detected

[0053] The results of industrial experiments show that the treatment method proposed by the invention is actually feasible, and the quality index of the finished product can meet the quality requirements of the raw materials required for the anhydrous magnesium chloride of the electrolytic metal magnesium or the flame retardant magnesium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com