Novel jack structure

A jack and a new type of technology, applied in the field of hydraulic jacks, can solve the problems of trouble, limit the scope of use of the jack, and the jack cannot be used upside down or flat, and achieve the effect of expanding the scope of use and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

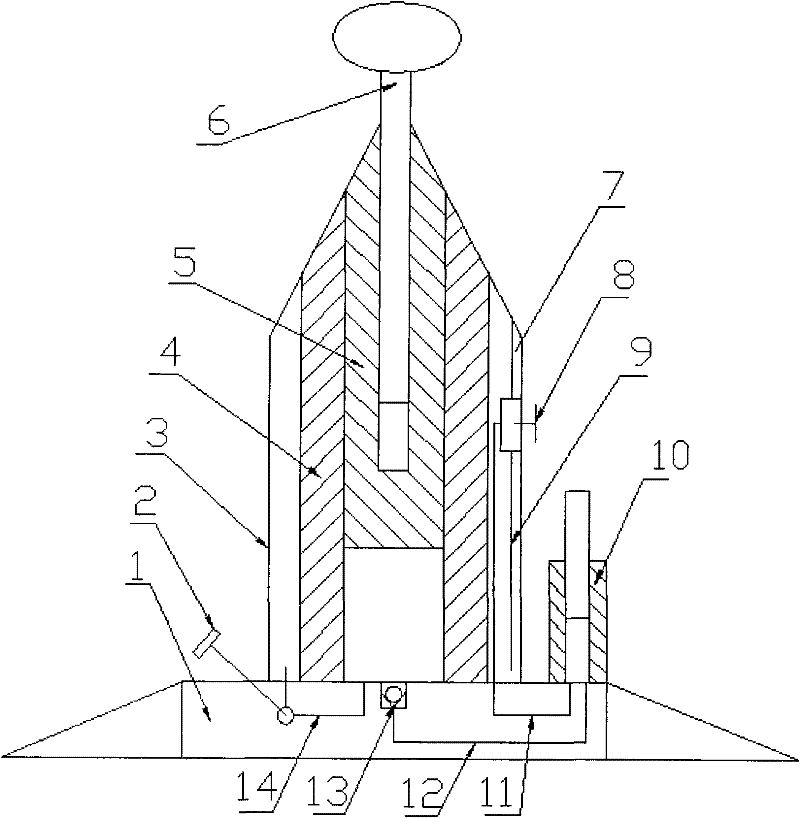

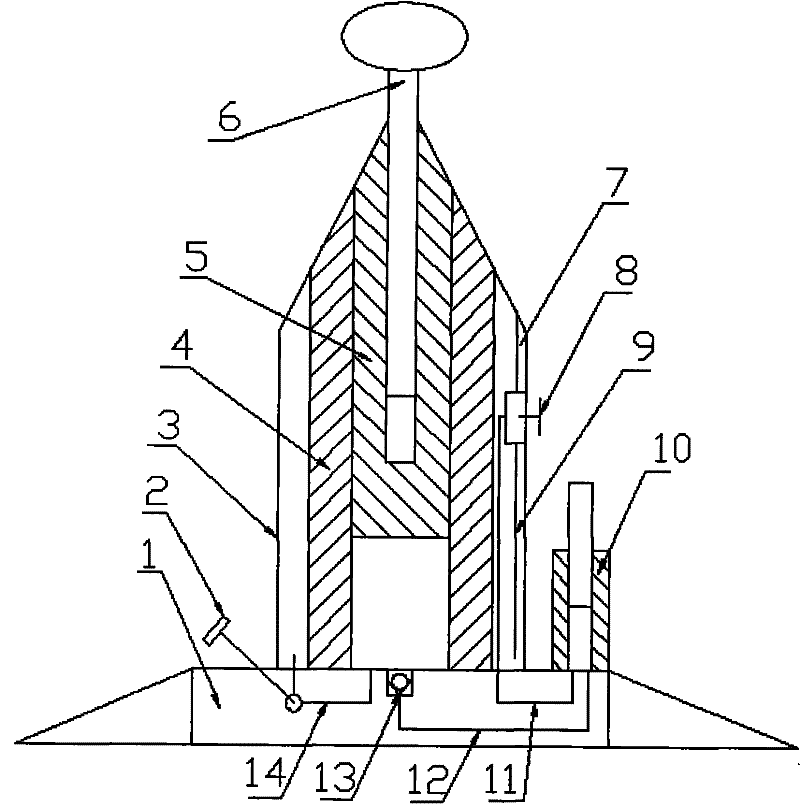

[0009] The structure of the jack has a main oil suction pipe (11), the main oil suction pipe (11), high pressure passage (12), oil discharge passage (14) are pre-set on the base (1), and the check valve (13) is set on the high pressure At the outlet end of the channel (12), the piston cylinder (4) is installed and fixed on the base (1), and a three-way valve (8) is arranged in the middle of the fuel tank (3), and the conversion handle of the three-way valve (8) is in the On the outside of the oil tank (3), connect the oil suction pipe A (7) and the oil suction pipe B (9) to the three-way valve (8) respectively, and connect the two ends of the main oil suction pipe (11) to the manual hydraulic pump (10) and One of the passages of the three-way valve (8) is connected, a piston (5) is installed in the piston cylinder (4), an adjusting screw (6) is installed on the piston (5), and the oil drain valve (2) is installed on the base The position in the middle of the oil drain passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com