Polysulfone membrane with supporting materials and preparation method thereof

A support material and polysulfone membrane technology, applied in the field of composite materials, can solve the problems of high manufacturing cost, high price, and unfavorable large-scale application of ultrafiltration membranes, and achieve high physical tensile strength and increased service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

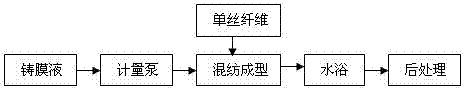

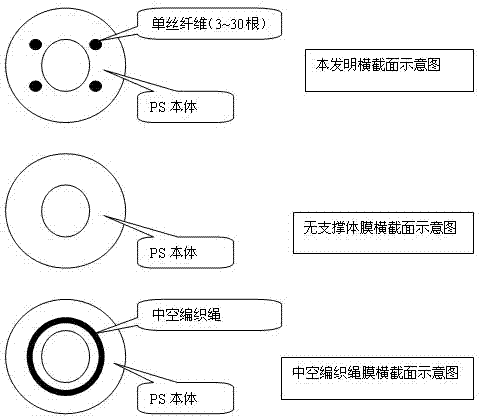

[0017] The steps of the preparation method of the polysulfone membrane with supporting material are as follows:

[0018] 1) Add polyethersulfone with a concentration of 16-18 wt / v%, additives with a concentration of 5-15 wt / v%, and solvents with a concentration of 50-80 wt / v% into the melting pot in sequence, and turn on the The stirring shaft is sealed with the pressure bar, and the casting solution is obtained after fully stirring at 60-100°C for 8-24 hours;

[0019] 2) Squeeze the casting solution into the tubular hollow fiber spinning spinneret. At the spinning speed of 15-40m / min, the casting solution is extruded by air pressure, filtered through the filter and metering pump into the spinneret for casting. The membrane liquid enters the hole, and the monofilament fiber entering the spinneret from the monofilament fiber entrance hole and the deionized water with the core liquid entering the hole enter the coagulation bath after composite molding of the spinneret, and then ...

Embodiment 1

[0022] 1) Add polyethersulfone with a concentration of 16 wt / v %, Tween 20 with a concentration of 5 wt / v %, and N,N-dimethylacetamide with a concentration of 50 wt / v % into the melting pot in turn, and turn on The stirring shaft of the melting pot is sealed and pressed, and the casting solution is obtained after fully stirring for 8 hours at 60°C;

[0023] 2) Squeeze the casting solution into the tubular hollow fiber spinning spinneret. At a spinning speed of 15m / min, the casting solution is extruded by air pressure, filtered through the filter and metering pump into the spinneret casting solution Entering the hole, the monofilament fiber entering the spinneret from the monofilament fiber entering hole and the deionized water entering the hole with the core liquid enter the coagulation bath after composite molding of the spinneret, and phase separation solidifies to form a film, and the coagulation bath The gel medium is water at a constant temperature, and the water temperat...

Embodiment 2

[0026] 1) Add polyethersulfone with a concentration of 18 wt / v %, polyethylene glycol with a concentration of 15 wt / v %, and N-methylpyrrolidone with a concentration of 80 wt / v % into the dissolving kettle in sequence, and turn on the dissolving kettle The agitator shaft is sealed with a pressure column, and the casting solution is obtained after fully stirring for 24 hours at 100°C;

[0027] 2) Squeeze the casting solution into the tubular hollow fiber spinning spinneret. At the spinning speed of 40m / min, the casting solution is extruded by air pressure, filtered through the filter and metering pump into the spinneret casting solution Entering the hole, the monofilament fiber entering the spinneret from the monofilament fiber entering hole and the deionized water entering the hole with the core liquid enter the coagulation bath after composite molding of the spinneret, and phase separation solidifies to form a film, and the coagulation bath The gel medium is water at a consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com