Compressing device of dust collecting barrel and control method thereof

A technology of a compression device and a control method, which is applied to the installation of electrical equipment, suction filters, etc., can solve the problems of increasing the daily use cost of vacuum cleaner users, large power consumption of vacuum cleaner products, and affecting dust cleaning of dust collection bins, so as to promote widespread popularization. and market application prospects, significant production practical significance, and the effect of enhancing product use experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

[0036] The working principle of the vacuum cleaner of the present invention is the same as that of the prior art. You can refer to the prior art, so it will not be described again:

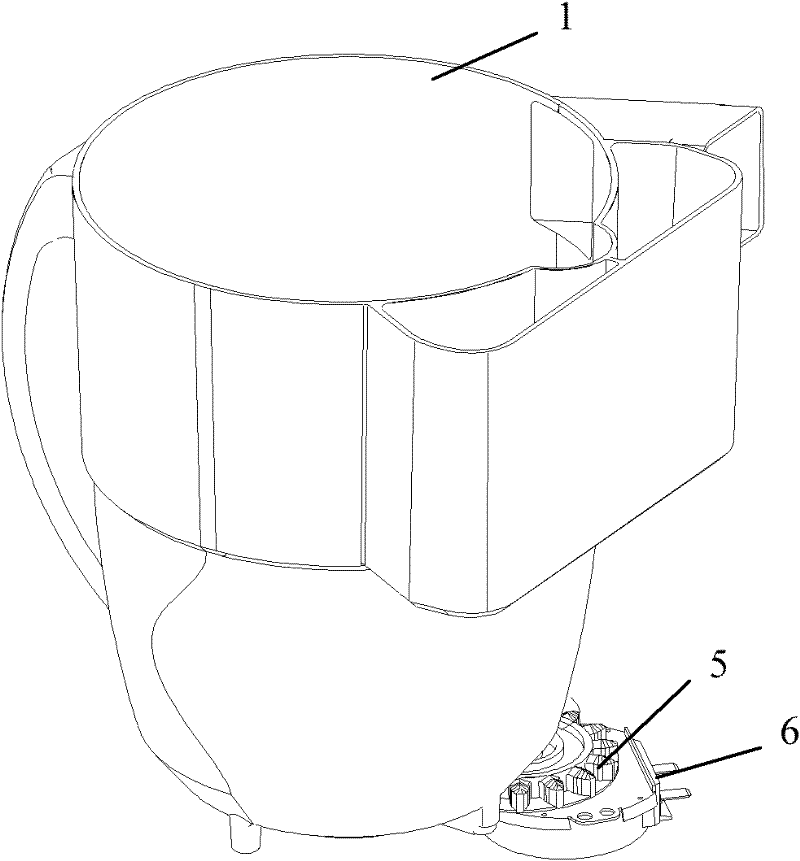

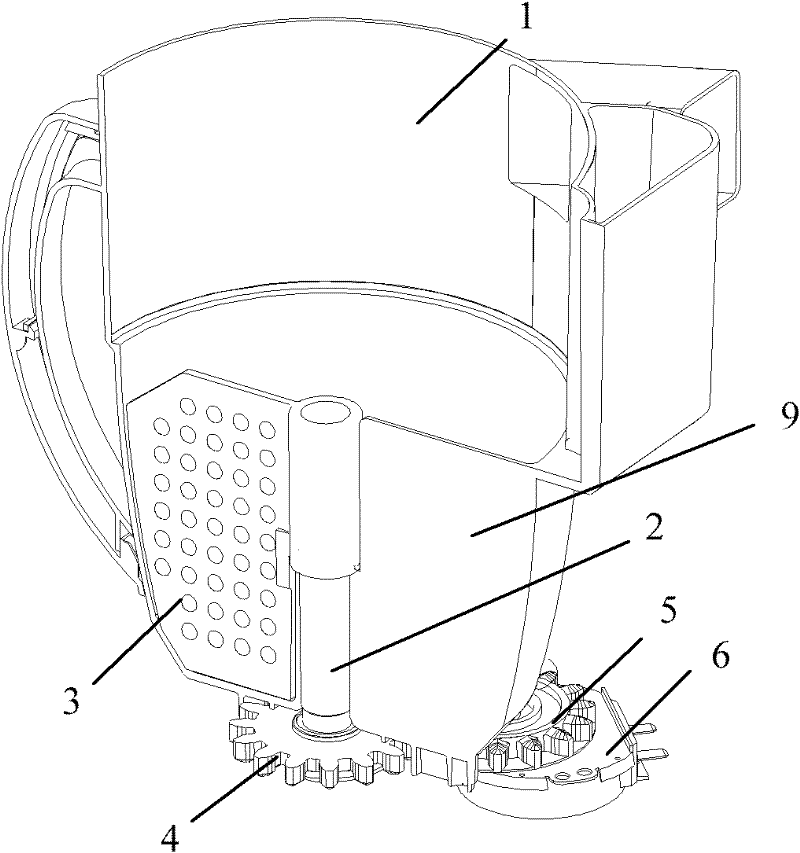

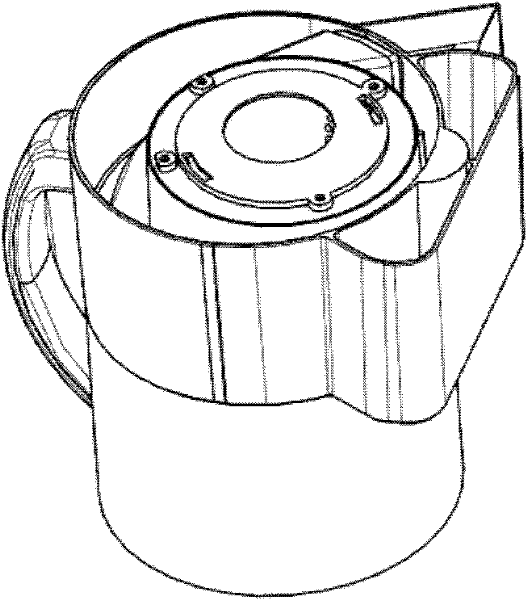

[0037] Figure 3-Figure 11 Shown is the best embodiment of the present invention. As shown in the figure, the dust collecting bucket of this embodiment includes a separation chamber 10 that separates the dust contained in the airflow, and collects and stores the dust separated from the separation chamber 10 The dust collection chamber 30 is a partition plate 20 that separates the separation chamber 10 and the dust collection chamber 30, and the partition plate 20 is provided with a dust hole 21 that can be selectively opened or closed.

[0038] Figure 6-Figure 9 The partition plate structure of the present invention is shown. The partition plate 20 of this embodiment inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com