Cooking control method of electric rice cooker

A control method, the technology of electric rice cooker, which is applied in the direction of temperature control by electric method, auxiliary controller with auxiliary heating device, cooking utensils, etc., which can solve the problem of overflow of steam port, poor cooking effect of rice, and longer cooking time, etc. problem, to achieve the effect of controlling the heating time and good cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

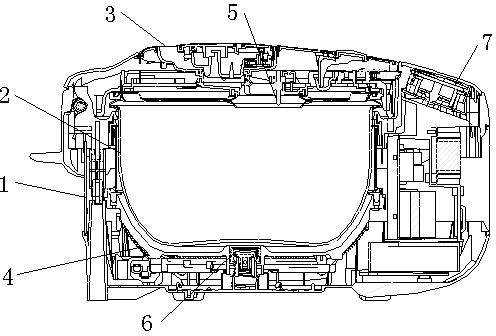

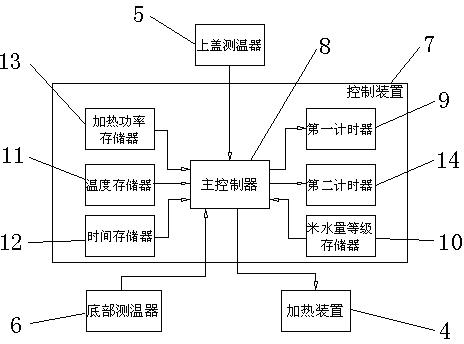

[0036] Such as figure 1 , figure 2 As shown, the electric rice cooker of the present embodiment includes a pot body 1, an inner container 2, an upper cover 3, a heating device 4 for heating the inner container, an upper cover temperature detector 5 arranged on the upper cover 3 for detecting the temperature of the upper cover, setting The bottom temperature detector 6 at the bottom of the pot body and the control device 7 arranged on the pot body for controlling the cooking work, the control device 7 includes a main controller 8 and a first timer 9 connected to the main controller respectively, Second timer 14, meter water level memory 10, temperature memory 11, time memory 12 and heating power memory 13. The output ends of the upper cover temperature detector 5 and the bottom temperature detector 6 are respectively connected with the input end of the main controller 8 , and the output end of the main controller 8 is electrically connected with the heating device 4 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com