Method for preparing instant tea through quantificationally matching

A quantitative blending and instant tea technology, which is applied in tea extraction and other directions, can solve the problems of non-standardized production of instant tea and poor batch consistency, and achieve the effect of improving product quality and batch consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

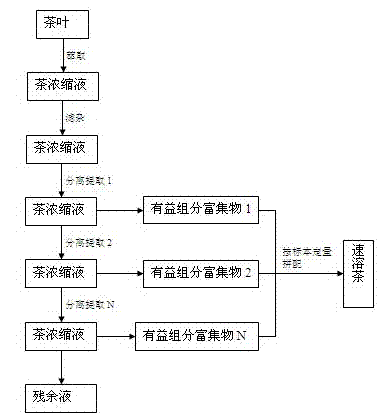

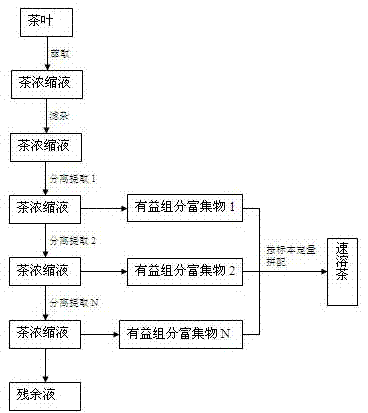

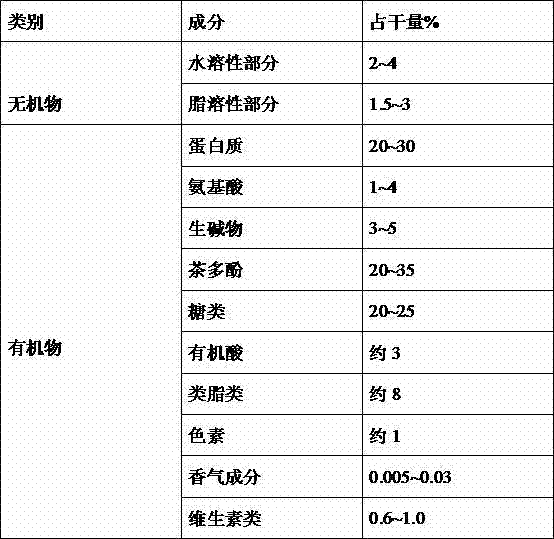

Method used

Image

Examples

Embodiment 1

[0050] The preparation of embodiment 1 Luzhou-flavor type Tieguanyin instant tea

[0051] Luzhou-flavor Tieguanyin is a kind of oolong tea, mainly produced in Anxi. Tea should be made according to the unique traditional processing technology, with the quality characteristics of Tieguanyin. Luzhou-flavor Tieguanyin sensory indicators are divided into five grades.

[0052] 1. Select Luzhou-flavor Tieguanyin super-grade tea 1KG as a sample, use supercritical carbon dioxide, at a temperature of 30°C and a pressure of 30MPa, add an appropriate amount of ethanol as an entrainer, and extract fully to obtain the extract.

[0053] 2. Add water, and perform ultrafiltration with a 100,000 molecular weight ultrafiltration membrane to remove macromolecular impurities to obtain a tea concentrate.

[0054] 3. Use a nanofiltration membrane with a molecular weight of 1000 for separation, and extract the beneficial component enrichment 1, whose main component is tea polysaccharide, and also...

Embodiment 2

[0063] The preparation of embodiment 2 fragrance type Tieguanyin instant tea

[0064] Fen-flavor Tieguanyin is a kind of oolong tea, mainly produced in Anxi. Tea should be made according to the unique traditional processing technology, with the quality characteristics of Tieguanyin. The sensory indicators of Fen-fragrance Tieguanyin are divided into four grades.

[0065] 1. Select 1KG of Fen-flavor Tieguanyin super-grade tea as a sample, extract with water, and obtain a tea concentrate after sufficient extraction.

[0066] 2. Filter the tea concentrate through a microfiltration membrane with a pore size of 0.1 μm to remove particle impurities;

[0067] 3. Use an ultrafiltration membrane with a molecular weight of 100,000 to carry out ultrafiltration to remove macromolecular impurities and obtain a tea concentrate.

[0068] 4. Use a nanofiltration membrane with a molecular weight of 1000 for separation, and extract the beneficial component enrichment 1, whose main componen...

Embodiment 3

[0076] The preparation of embodiment 3 Longjing instant green tea

[0077] Longjing tea is a kind of green tea, produced in Xihu District, Hangzhou City.

[0078] 1. Select 1KG of first-grade Longjing tea as a sample, use supercritical carbon dioxide, add an appropriate amount of ethanol as an entrainer at a temperature of 30°C and a pressure of 30MPa, and extract fully to obtain the extract.

[0079] 2. Add water, carry out ultrafiltration with a 50,000 molecular weight ultrafiltration membrane, remove macromolecular impurities, and obtain a tea concentrate.

[0080] 4. Use a nanofiltration membrane with a molecular weight of 1000 for separation, and extract the beneficial component enrichment 1, whose main component is tea polysaccharide, and also includes tea polyphenols, various minerals, aromatic substances and other beneficial components.

[0081] 5. A nanofiltration membrane with a molecular weight of 500 is selected for separation, and the beneficial component enric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com