Automatic fly larva pupating separation device

An automatic separation and pupation technology, which is applied in animal husbandry and other fields, can solve the problems of reducing the emergence rate of fly pupae, drowning, and reducing work efficiency, so as to avoid drowning, improve efficiency, and prevent flight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

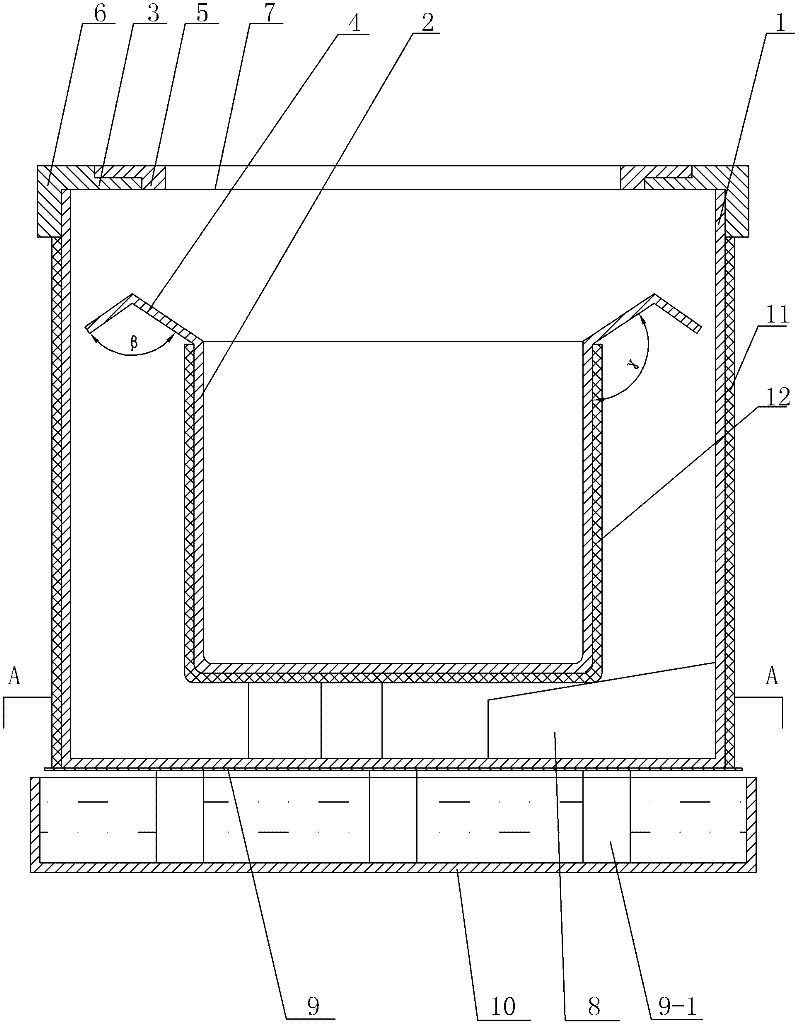

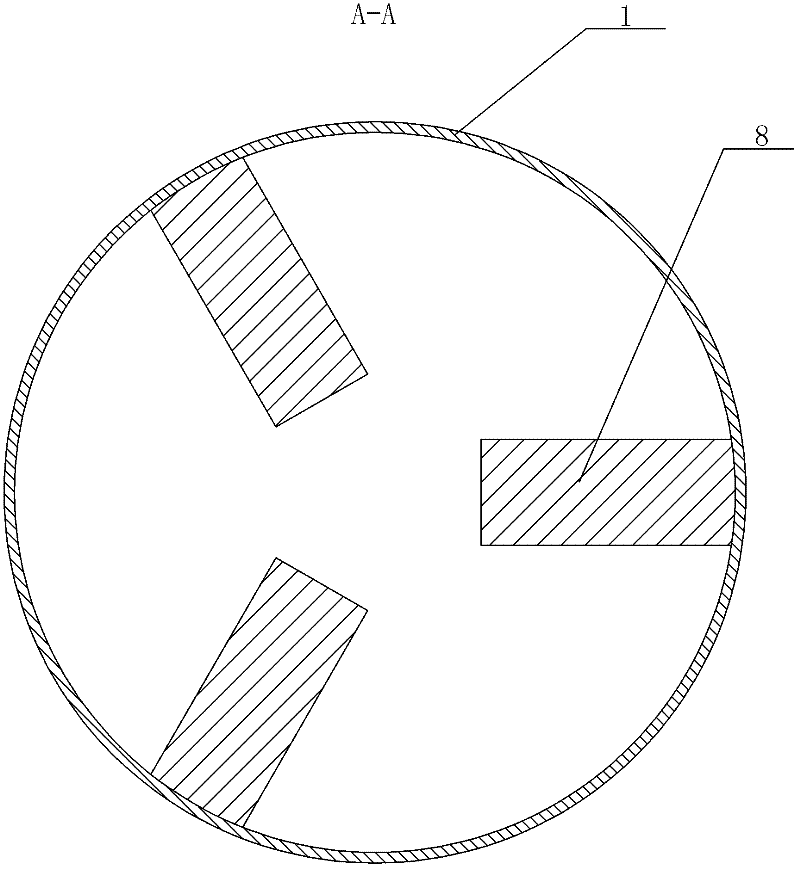

[0007] Specific implementation mode one: combine Figure 1 to Figure 5 To illustrate this embodiment, a fly maggot pupation automatic separation device described in this embodiment includes an outer cylinder 1, an inner cylinder 2 and a cylinder head assembly 3, and the opening edge of the inner cylinder 2 is provided with an inverted V-shaped Edge 4, the inner cylinder 2 is placed in the outer cylinder 1, and the cylinder head assembly 3 is buckled at the opening of the outer cylinder 1.

specific Embodiment approach 2

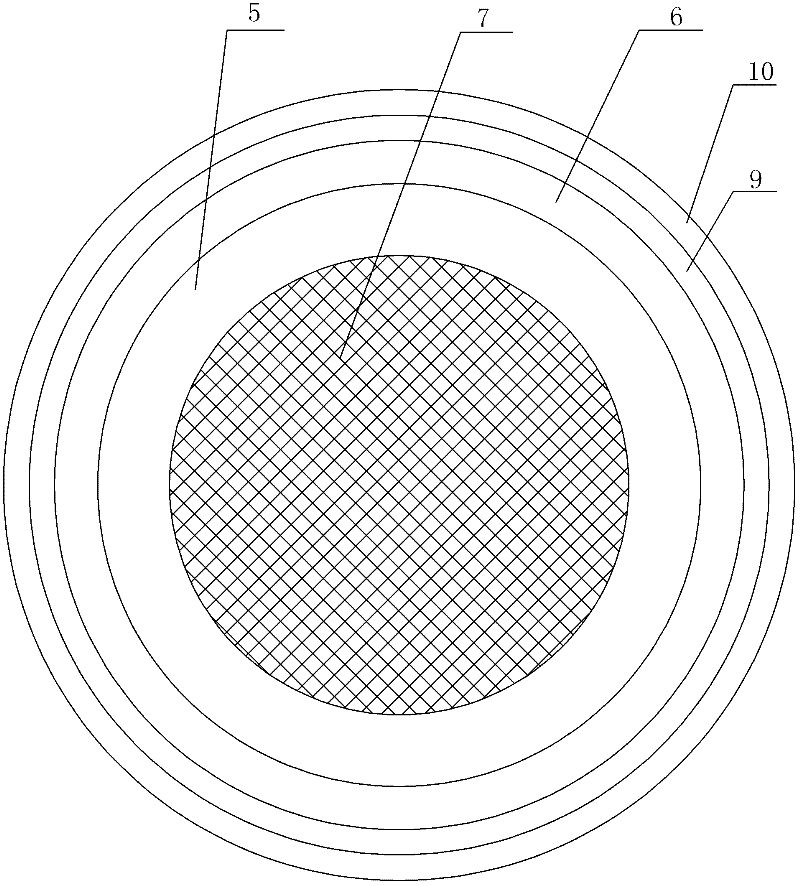

[0008] Specific implementation mode two: combination figure 1 , Figure 4 with Figure 5 Describe this embodiment, the cylinder head assembly 3 of a kind of fly maggot pupation automatic separation device described in this embodiment includes an upper cover 5, a lower cover 6 and a nylon net 7, and the middle part of the lower cover 6 has a first through hole 6-1, the hole wall of the first through hole 6-1 is provided with an annular flange 6-2, and the upper cover 5 and the nylon mesh 7 are sequentially installed on the annular flange 6-2 from top to bottom, A second through hole 5-1 is opened in the middle of the upper cover 5, and the centerline of the second through hole 5-1 coincides with the centerline of the first through hole 6-1. This embodiment prevents fly larvae from fleeing during the growth process, and the nylon mesh 7 ensures the smooth flow of air in the outer cylinder 1 and the inner cylinder 2. Other components and connections are the same as those in th...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 Describe this embodiment, the included angle β of the opening of the inverted V-shaped edge 4 of the automatic separation device for fly maggot pupation described in this embodiment is 105°, and the side where the inverted V-shaped edge 4 is connected to the opening edge of the inner cylinder 2 The angle γ with the outer wall of the inner cylinder 2 is 120°. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com