Energy-saving totally enclosed boiler

A fully enclosed, energy-saving technology, applied in the field of boilers, can solve the problems of incomplete combustion of fuel, air pollution, poor sealing effect, etc., and achieve the effect of reducing heat loss, improving energy saving effect and reducing heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further illustrate the purpose of the present invention, the following specific embodiments are specifically cited, but the scope of rights required by the present invention is not limited thereto:

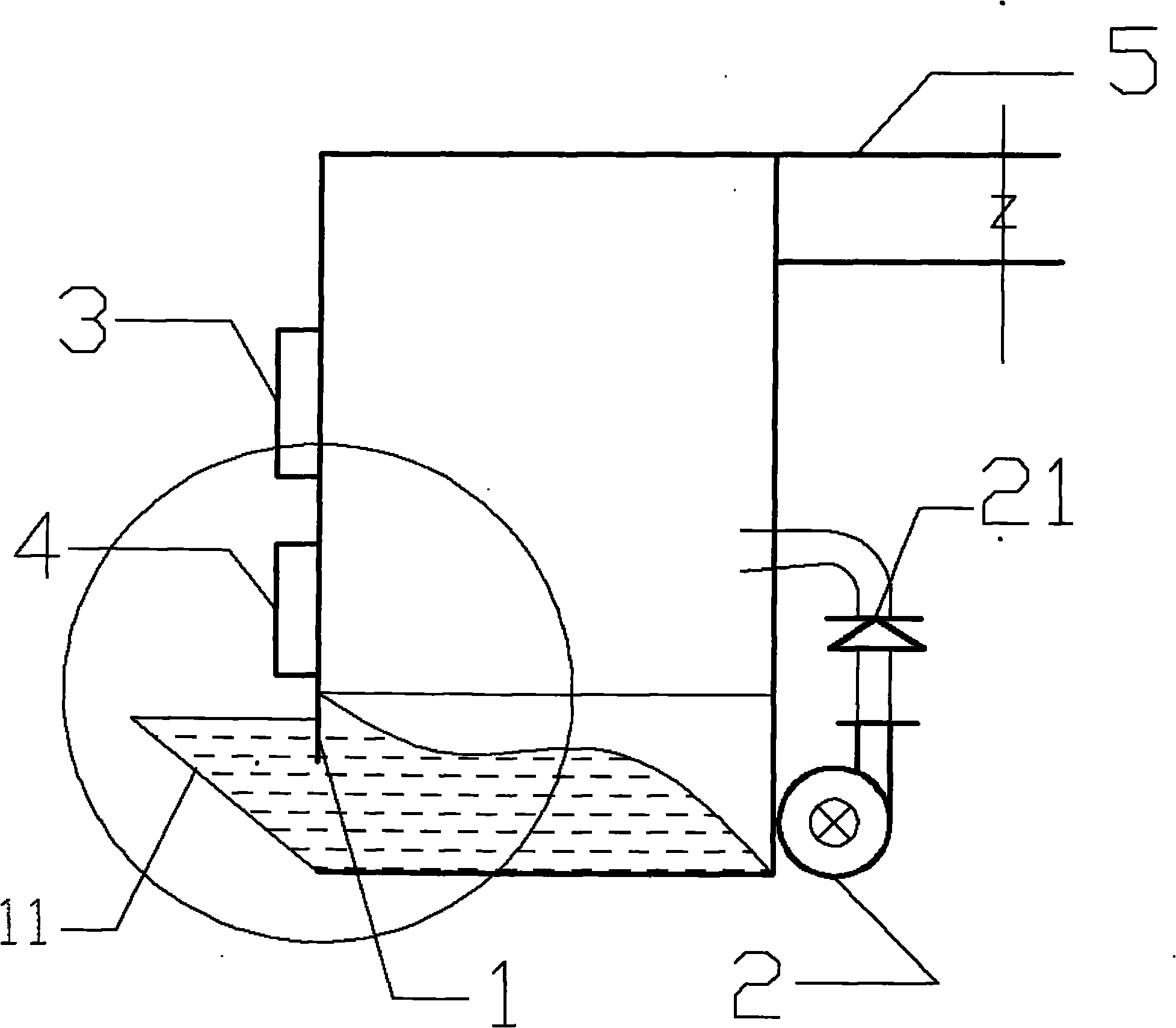

[0017] An energy-saving fully enclosed boiler comprises an upper furnace door 3, a lower furnace door 4 and a blower 2 for forced air supply, and a water seal ring 1 is provided at the lower part of the boiler. in:

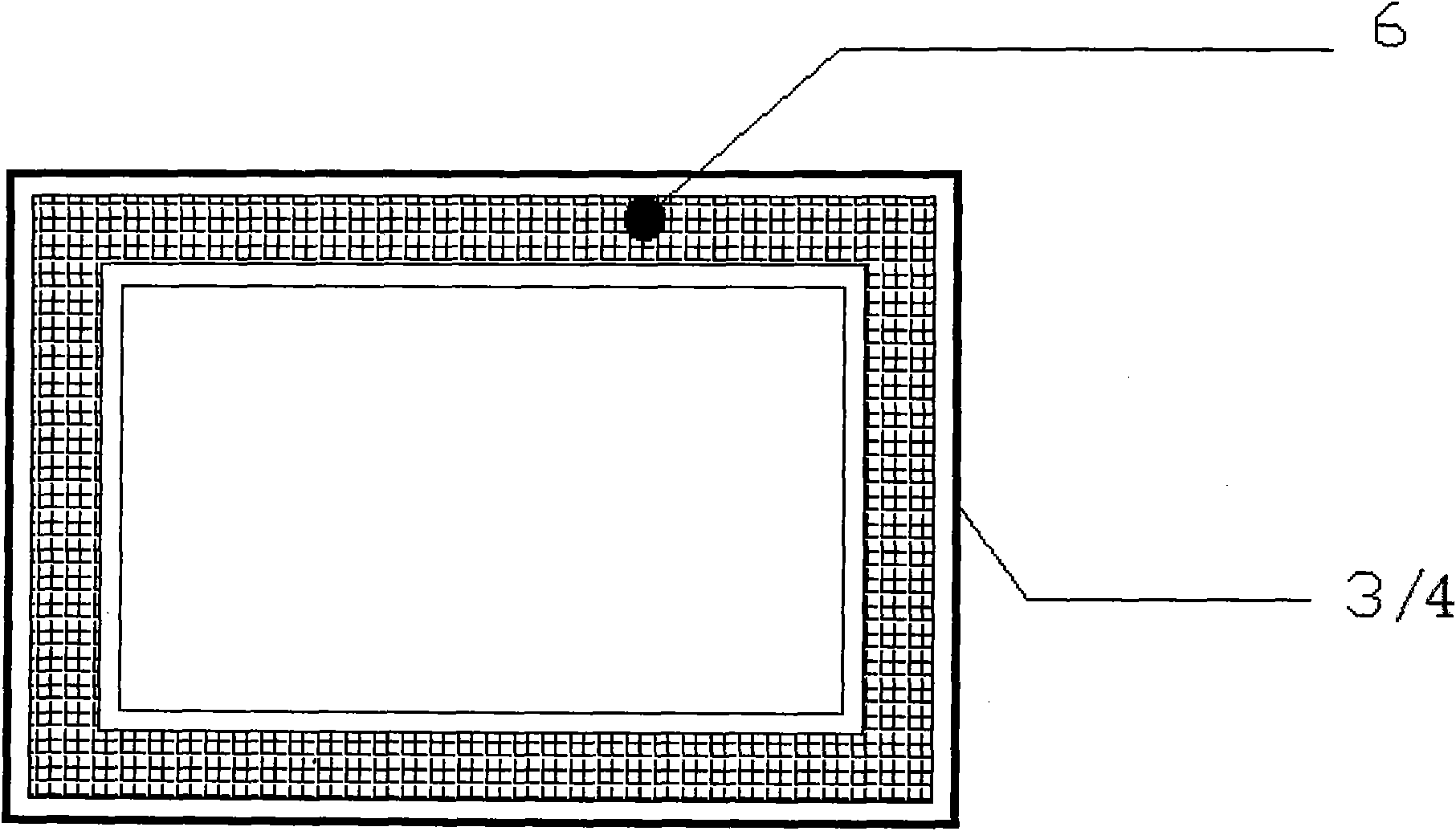

[0018] Both the upper furnace door 3 and the lower furnace door 4 can be filled with fuel, and the upper furnace door 3 and the lower furnace door 4 are closed furnace doors with sealing rings 6;

[0019] There is a non-return damper 21 between the blower 2 and the boiler to prevent the boiler from flowing back into the blower 2 and achieve a better sealing effect.

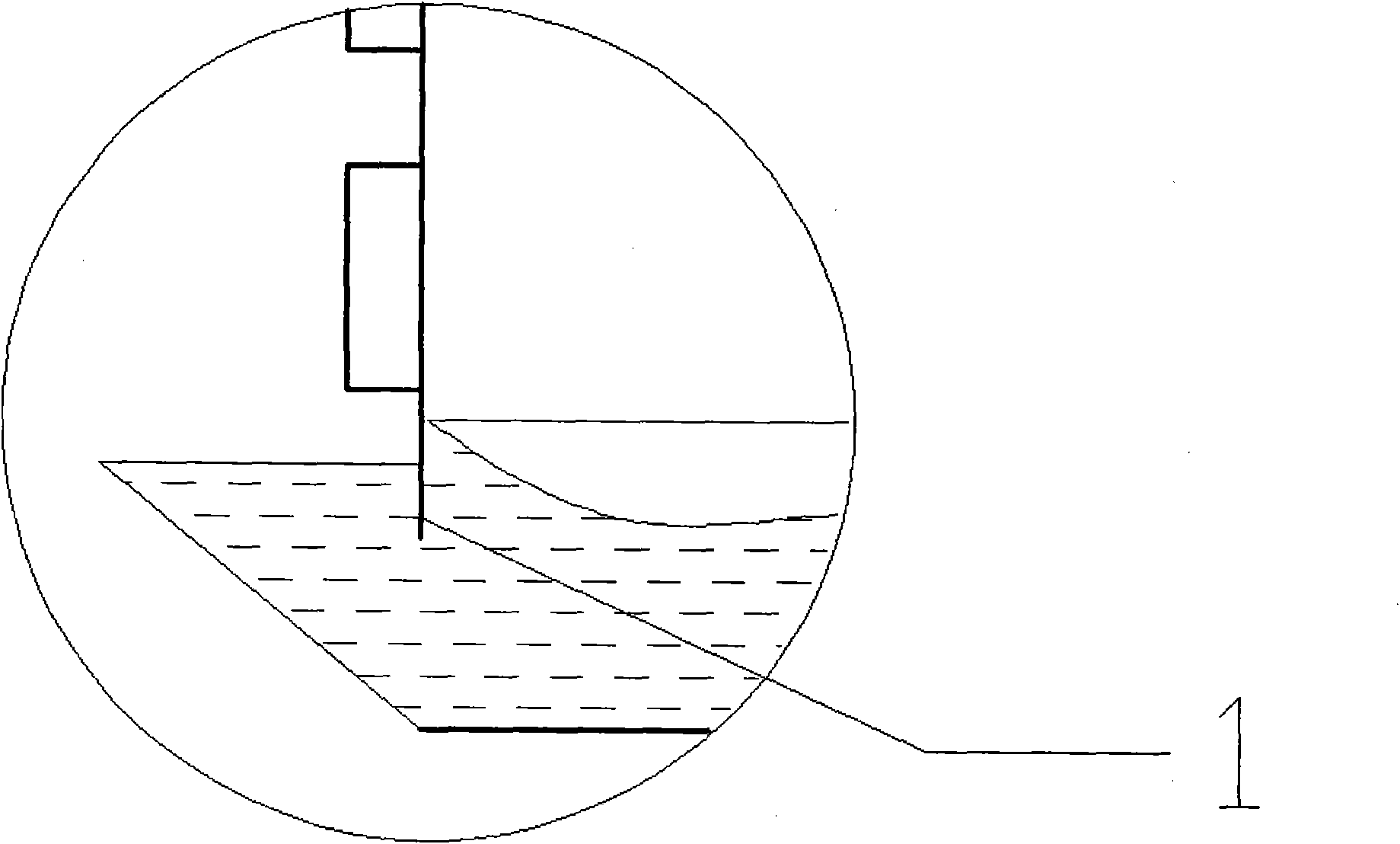

[0020] There is an opening 11 outside the water seal ring 1, so that the inside of the boiler communicates with the outside world.

[0021] When the boiler is running, there are two m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com