Novel liquid cooling motorcycle cooler

A technology for motorcycles and coolers, which is applied in liquid cooling, engine cooling, machine/engine, etc. It can solve the problems of engine heat being taken away in time, the gap becomes smaller, and the cooling effect of air cooling is not particularly ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

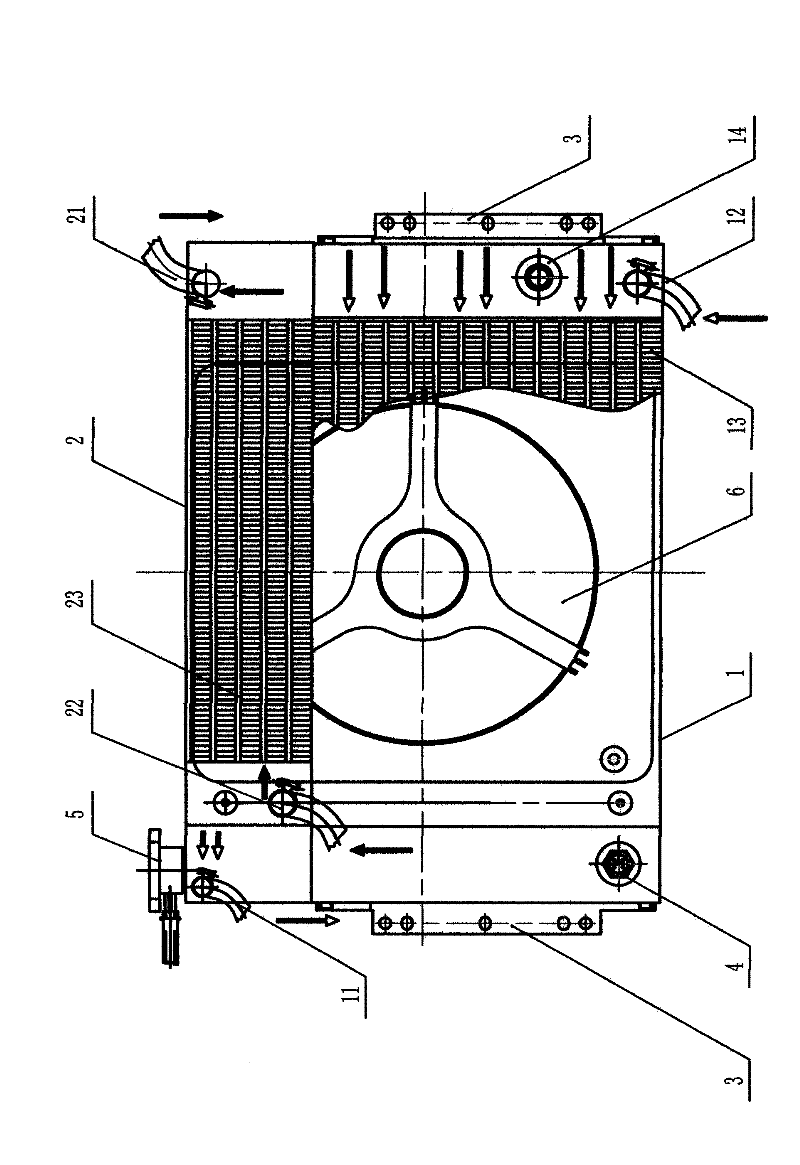

Embodiment 1

[0027] Embodiment one, such as figure 1 A new type of liquid-cooled motorcycle cooler shown includes a liquid cooler 1 and an oil cooler 2, and a coolant tank 5 is arranged at the upper end of the liquid cooler 1, wherein the liquid cooler 1 includes an external liquid Cooling radiator 13, coolant inlet 11 connected to the upper end of the engine water jacket (not shown in the figure), coolant outlet 12 connected to the lower end of the engine water jacket and coolant pump 14, water jacket, coolant outlet 12 , coolant pump 14, liquid-cooled radiator 13, and coolant inlet 11 are connected in turn to form a circulation; the oil cooler 2 includes an external oil radiator 23, and the engine oil pump inside the engine crankcase (not shown in the figure) ) port connected to the oil outlet 22 and the oil inlet 21 connected to the bottom of the crankcase body of the engine, the oil arranged in the crankcase body passes through the oil pump, passes through the oil outlet 22 to the oil ...

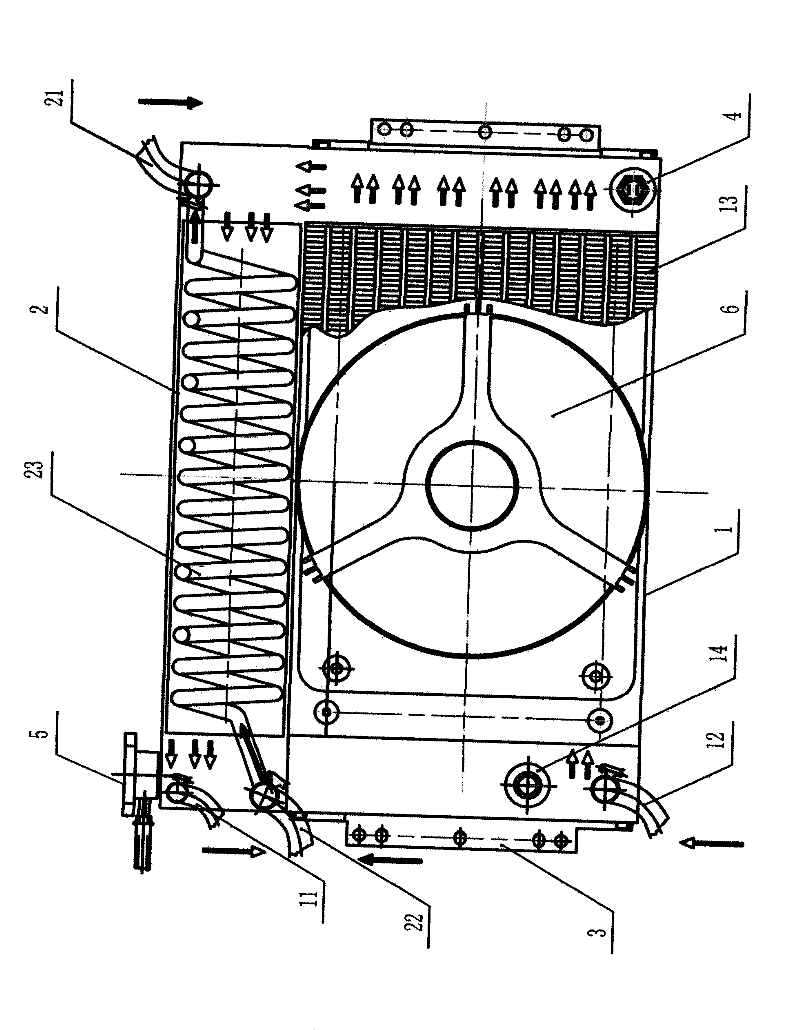

Embodiment 2

[0029] Embodiment two, such as figure 2 , Figure 8 , Figure 9A new type of liquid-cooled motorcycle cooler shown includes a liquid cooler 1 and an oil cooler 2, and a coolant tank 5 is arranged at the upper end of the liquid cooler 1, wherein the liquid cooler 1 includes an external liquid Cooling radiator 13, coolant inlet 11 connected to the upper end of the engine water jacket (not shown in the figure), coolant outlet 12 connected to the lower end of the engine water jacket and coolant pump 14, water jacket, coolant outlet 12 , coolant pump 14, liquid-cooled radiator 13, and coolant inlet 11 are connected in turn to form a circulation; the oil cooler 2 includes an external oil radiator 23, and the engine oil pump inside the engine crankcase (not shown in the figure) ) port connected to the oil outlet 22 and the oil inlet 21 connected to the bottom of the crankcase body of the engine, the oil arranged in the crankcase body passes through the oil pump, passes through the...

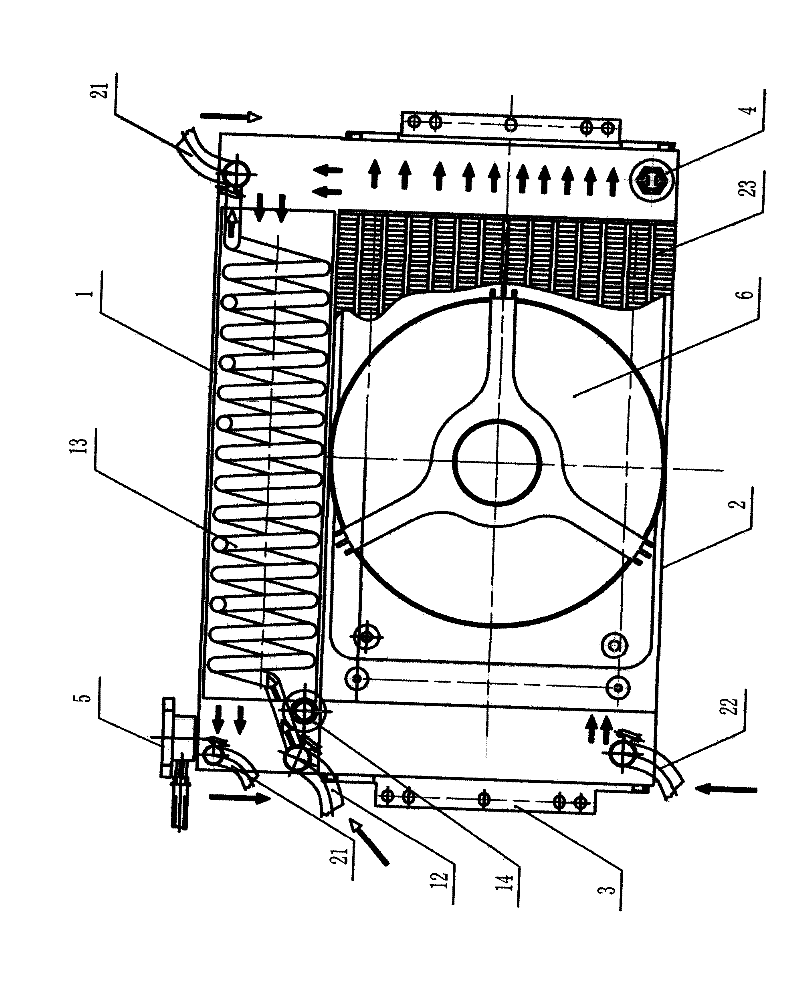

Embodiment 3

[0031] Embodiment three, such as image 3 A new type of liquid-cooled motorcycle cooler shown includes a liquid cooler 1 and an oil cooler 2, and a coolant tank 5 is arranged at the upper end of the liquid cooler 1, wherein the liquid cooler 1 includes an external liquid Cooling radiator 13, coolant inlet 11 connected to the upper end of the engine water jacket (not shown in the figure), coolant outlet 12 connected to the lower end of the engine water jacket and coolant pump 14, water jacket, coolant outlet 12 , coolant pump 14, liquid-cooled radiator 13, and coolant inlet 11 are connected in turn to form a circulation; the oil cooler 2 includes an external oil radiator 23, and the engine oil pump inside the engine crankcase (not shown in the figure) ) port connected to the oil outlet 22 and the oil inlet 21 connected to the bottom of the crankcase body of the engine, the oil arranged in the crankcase body passes through the oil pump, passes through the oil outlet 22 to the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com