Steel for electric power tower and production method thereof

A power tower and molten steel technology, applied in the field of steel rolling, can solve problems such as low strength, difficult galvanizing, and low welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

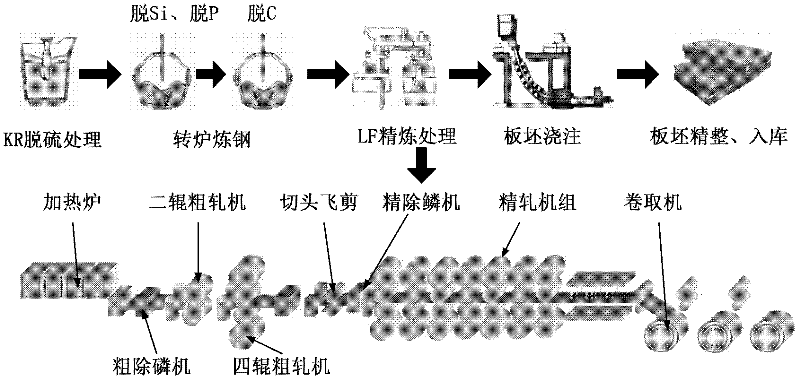

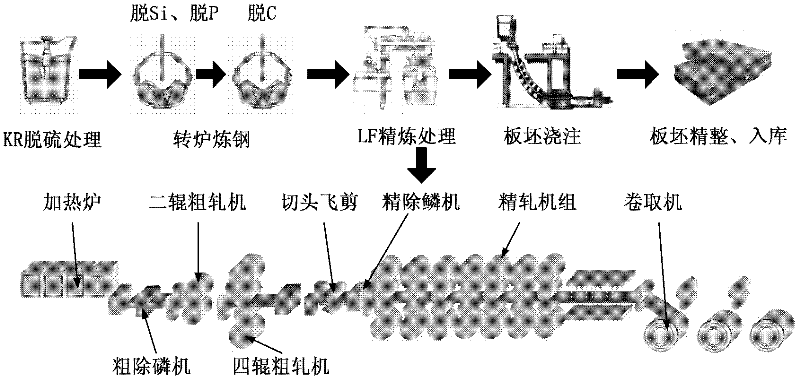

[0032] The molten iron is subjected to KR desulfurization treatment, full three desulfurization converter smelting, and LF furnace refining treatment before continuous casting; the slab smelting composition is: C: 0.07wt%, Si: 0.02wt%, Mn: 1.10wt%, P : 0.010wt%, S: 0.003wt%, V: 0.04wt%, Ti: 0.035wt%, Alt: 0.035wt%, the balance is Fe and other unavoidable impurity elements.

[0033] The slab is heated to 1180°C, the heating time is 3.5 hours, the final rolling temperature is 820°C, and the coiling temperature is 620°C; after rough rolling, finishing rolling, and laminar cooling, coiling is carried out. Finally, GR.65 steel for power towers was obtained, with a yield strength of 560MPa, a tensile strength of 630MPa and an elongation of 31%, a thickness of 15.8mm, and a width of 1800mm.

Embodiment 2

[0035] The molten iron is subjected to KR desulfurization treatment, full three desulfurization converter smelting, and LF furnace refining treatment before continuous casting; the slab smelting composition is: C: 0.06wt%, Si: 0.03wt%, Mn: 1.20wt%, P : 0.008wt%, S: 0.003wt%, V: 0.036wt%, Ti: 0.032wt%, Alt: 0.040wt%, the balance is Fe and other unavoidable impurity elements.

[0036] The slab is heated to 1200°C, the heating time is 3.3 hours, the final rolling temperature is 840°C, and the coiling temperature is 650°C; after rough rolling, finish rolling, and laminar cooling, coiling is carried out. Finally, GR.65 steel for power towers was obtained, with a yield strength of 570MPa, a tensile strength of 680MPa, an elongation of 35%, a thickness of 3.2mm, and a width of 1200mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com