Halogen-free flame-retardant nylon 66 composite material and preparation method thereof

A composite material and flame-retardant technology, applied in the field of polymers, can solve problems such as restrictions and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In addition, the present invention also provides a preparation method of a halogen-free flame-retardant nylon 66 composite material, comprising the following steps:

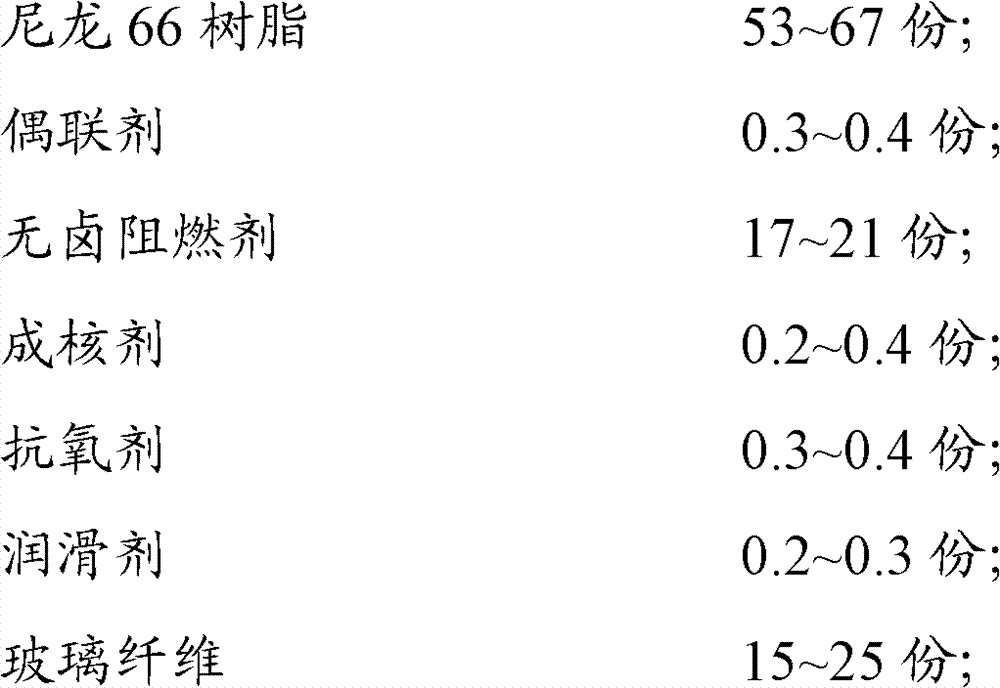

[0032] Weigh each component by weight as follows:

[0033]

[0034]

[0035] Among them, the halogen-free flame retardant is a mixture of halogen-free organic phosphine flame retardants and intumescent phosphorus-nitrogen flame retardants;

[0036] After mixing the above-mentioned raw materials except glass fiber evenly, extrude to granulate, and add glass fiber during extrusion, wherein the temperature during extrusion is controlled at 200-250°C.

[0037] The above-mentioned halogen-free flame-retardant nylon 66 composite material is made of nylon 66 resin, halogen-free flame retardant, glass fiber, nucleating agent and other additives through high-temperature extrusion and granulation. The material has a good flame-retardant effect and can reach UL-94. V-0 level, in line with flame retardant requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com