Reaction device for deep treatment of drinking water and method for deep treatment of drinking water by water factory

A technology for advanced treatment and drinking water, applied in chemical instruments and methods, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as the powerlessness of ammonia nitrogen and limited ability to remove micro-pollutants, and achieve a large amount of engineering , good process adaptability, and the effect of covering a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

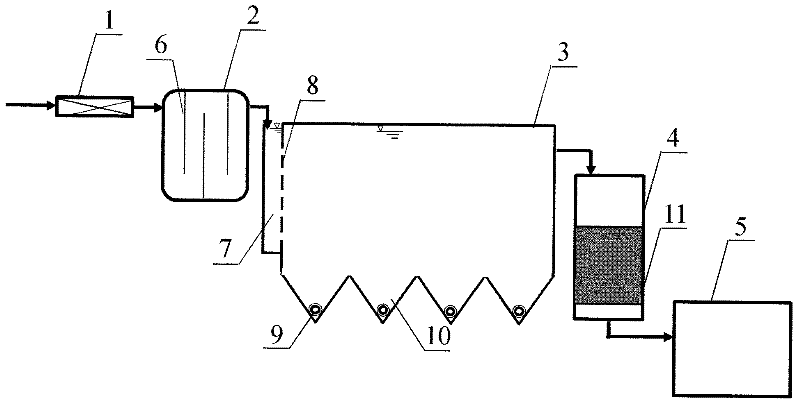

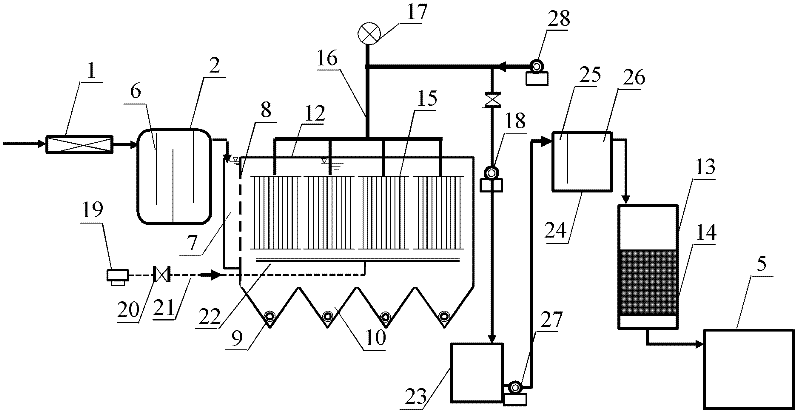

[0072] Please refer to the figure, the reactor for advanced treatment of drinking water includes static mixer 1, coagulation reaction tank 2, clear water tank 5, perforated plate 8, sludge tank 10, ultrafiltration membrane tank 12, granular activated carbon filter tank 13, granular activated carbon Filter bed 14, ultrafiltration membrane module 15, outlet pipe 16, vacuum gauge 17, suction pump 18, air compressor 19, aeration pipeline 21, aeration device 22, intermediate pool 23, main ozone oxidation tank 24 and lifting pump 27, etc.;

[0073] A perforated plate 8 is installed in the ultrafiltration membrane pool 12, and the top of the space formed between one side of the perforated plate 8 and the pool wall of the ultrafiltration membrane pool 12 is set to an opening; The other side of the perforated plate 8 is equipped with 4 groups of ultrafiltration membrane modules 15 to form a membrane filtration area, and the ultrafiltration membrane modules are submerged membrane module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com