Self-propelled compensating return stroke sweeper for conveying belt

A technology for conveyor belts and cleaners, which is applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc. It can solve the problems of cleaning rubber without automatic compensation, limit state cannot be predicted in time, and the flexibility adjustment of the surface of the conveyor belt is not flexible enough. , to achieve the effects of enhanced reliability, small footprint, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

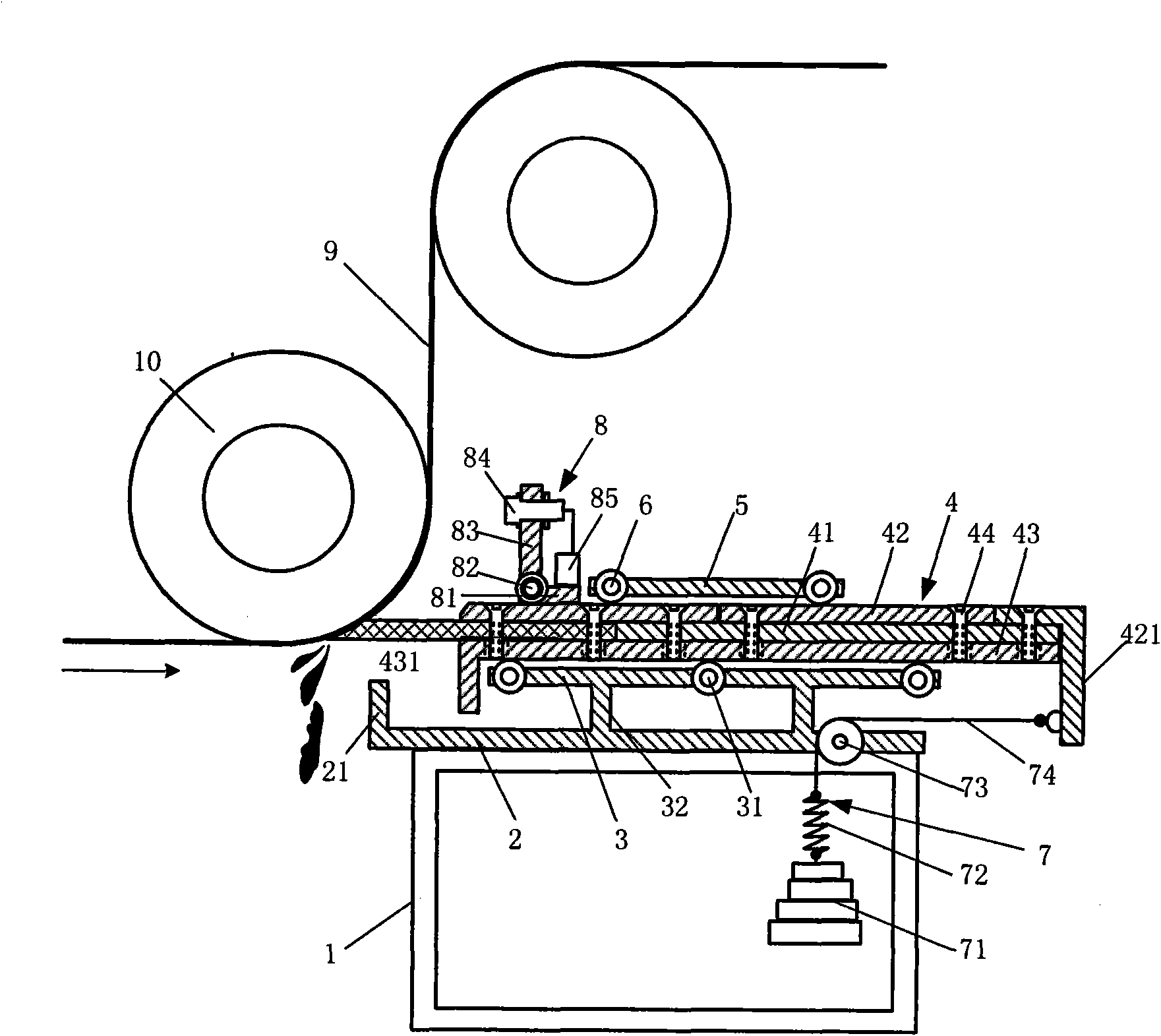

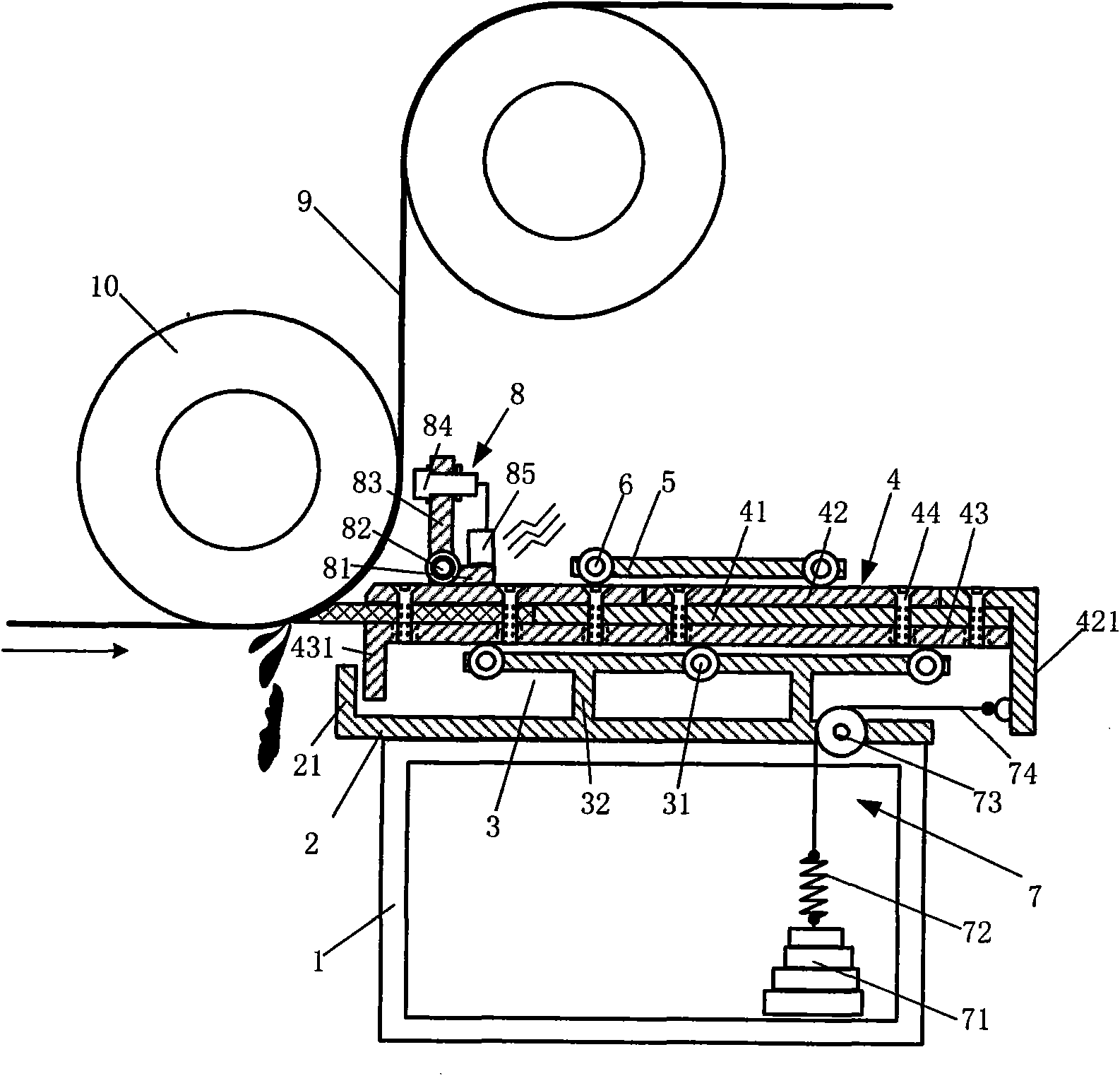

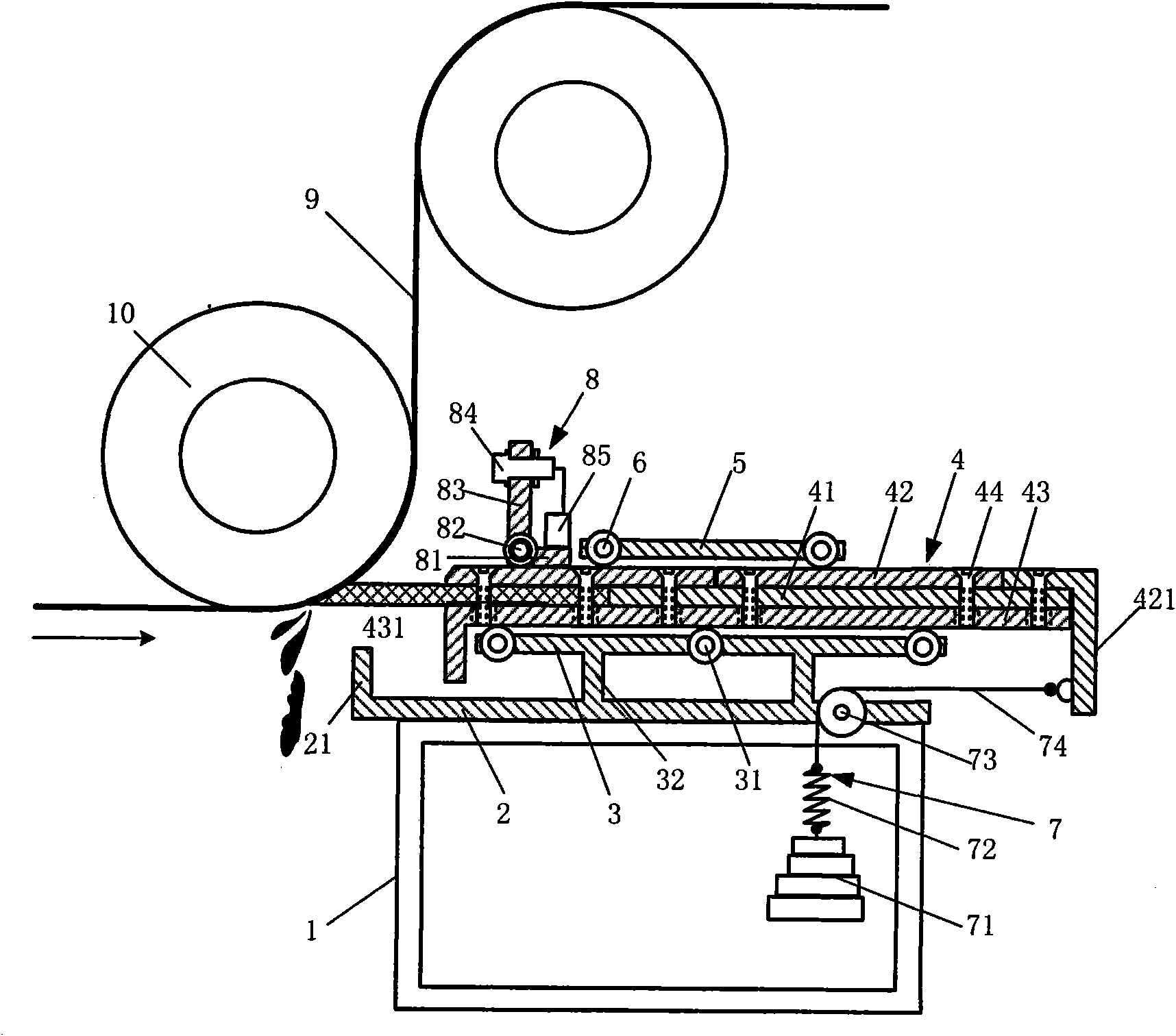

[0021] see figure 1 , figure 2 , the self-propelled and compensated reverse conveyor belt cleaner of the present invention includes a base 1; a base plate 2 is arranged on the base 1, and one end of the conveyor belt protrudes from the base 1 and bends upward to form a stop where the cleaner reaches the limit position. Position stopper 21; the lower idler seat 3 is fixed on the bottom plate 2 through a bracket 31, and several idler rollers 32 are arranged along the length direction of the lower idler seat;

[0022] The cleaner frame 4 is set on the idler roller 32 of the lower idler seat, including the cleaning rubber 41, the upper and lower splints 42, 43 and bolts 44 clamping the cleaning rubber 41; the end of the lower splint 43 close to the conveyor belt extends out of the lower idler seat 3 and bent downward to form a synchronous shift block 431 of the cleaner, corresponding to the stop block 21 of the bottom plate 2; the upper splint 42 is bent downward to form a fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com