Method for preparing medium density fiberboard by using microwave to pre-heat

A medium density and fiberboard technology, which is applied in the field of medium density fiberboard preheated by microwave, can solve the problem of prolonged production process time of medium density fiberboard, the quality of medium density fiberboard not meeting the requirements, and rapid molding and curing of fiber blanks, etc. problems, to achieve the effect of shortening the overall preparation time, improving quality, and reducing the heating time of hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

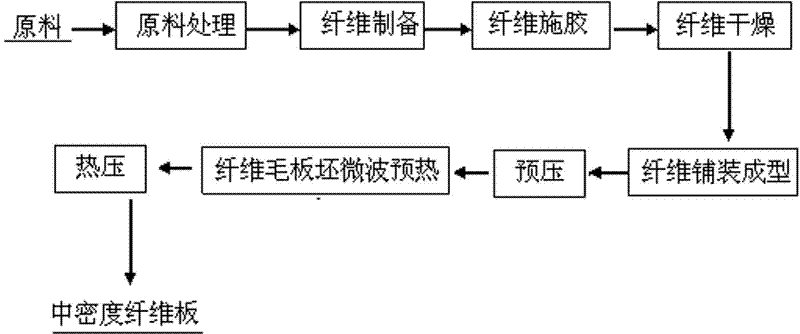

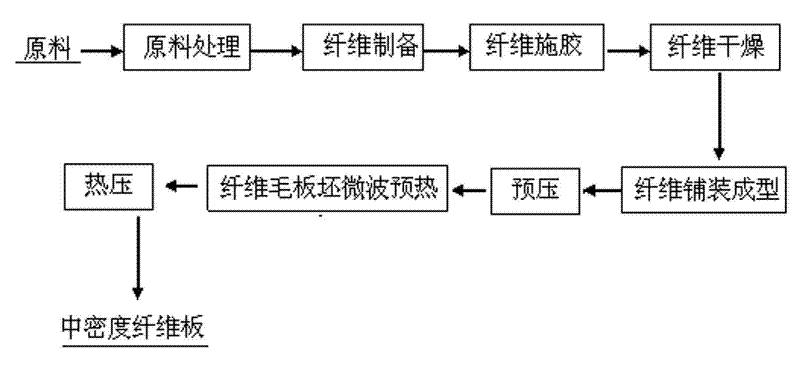

Image

Examples

Embodiment 1

[0012] Embodiment 1: A method for preparing medium density fiberboard utilizing microwave preheating, including raw material treatment, fiber preparation, fiber sizing, fiber drying, fiber laying and molding, pre-pressing, and hot-pressing processes, and also includes pre-pressing processes and A microwave preheating process for the fiber rough slab is added between the hot pressing process. In the fiber rough slab microwave preheating process, a set of continuous tunnel microwave heating device is provided. The continuous tunnel microwave heating device includes a tunnel heating box for fiber rough slab transportation and a The microwave emission mechanism, the tunnel-type heating box is 4 meters long and 2.8 meters wide, and the two ends of the tunnel-type heating box are used to input and output fiber rough slabs. There are feeding and discharging covers to prevent microwave leakage; The microwave transmitting mechanism includes 70 magnetrons, and the power of a single magn...

Embodiment 2

[0013] Embodiment 2: A method for preparing medium density fiberboard utilizing microwave preheating, including raw material treatment, fiber preparation, fiber sizing, fiber drying, fiber laying and molding, pre-pressing, hot-pressing processes, and also includes pre-pressing process and A microwave preheating process for the fiber rough slab is added between the hot pressing process. In the fiber rough slab microwave preheating process, a set of continuous tunnel microwave heating device is provided. The continuous tunnel microwave heating device includes a tunnel heating box for fiber rough slab transportation and a The microwave emission mechanism, the tunnel-type heating box is 12 meters long and 1.4 meters wide, and the two ends of the tunnel-type heating box are used to input and output fiber rough slabs. There are feeding and discharging covers to prevent microwave leakage; The microwave transmitting mechanism includes 175 magnetrons, and the power of a single magnetro...

Embodiment 3

[0014] Embodiment 3: A method for preparing medium density fiberboard utilizing microwave preheating, including raw material treatment, fiber preparation, fiber sizing, fiber drying, fiber laying and molding, pre-pressing, and hot-pressing processes, and also includes pre-pressing processes and A microwave preheating process for the fiber rough slab is added between the hot pressing process. In the fiber rough slab microwave preheating process, a set of continuous tunnel microwave heating device is provided. The continuous tunnel microwave heating device includes a tunnel heating box for fiber rough slab transportation and a The microwave emitting mechanism, the tunnel-type heating box is 8 meters long and 2 meters wide, and the two ends of the tunnel-type heating box are used for inputting and outputting fiber rough slabs, and are connected with a feeding cover and a discharging cover to prevent microwave leakage; The microwave transmitting mechanism includes 120 magnetrons, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com