Ferrule perforation method

A ferrule and punching device technology, applied in boring/drilling, drilling/drilling equipment, clamping, etc., can solve the problems of many defective products, low efficiency, inconsistent machining accuracy, etc., and reduce defective products. , Improve efficiency and ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings of the description.

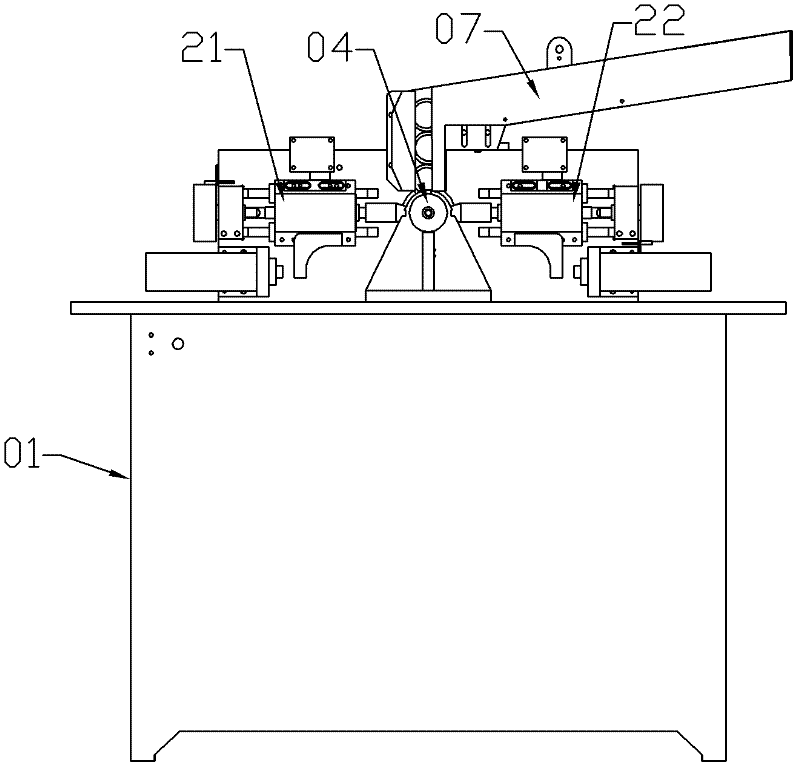

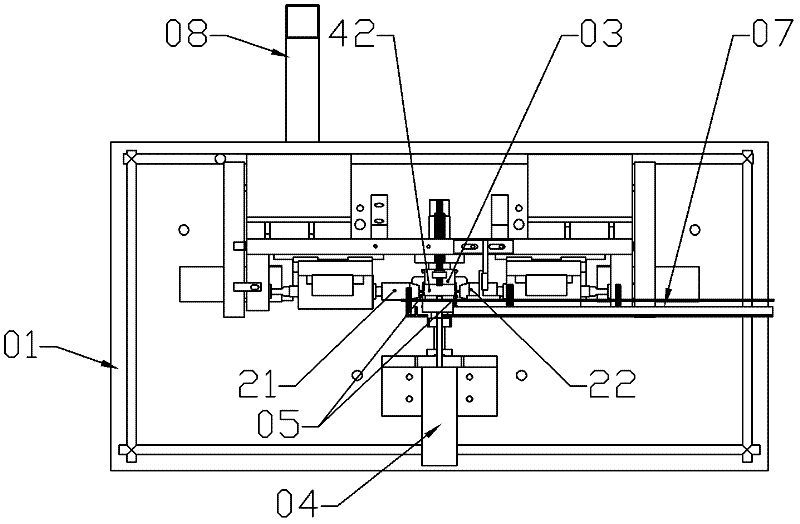

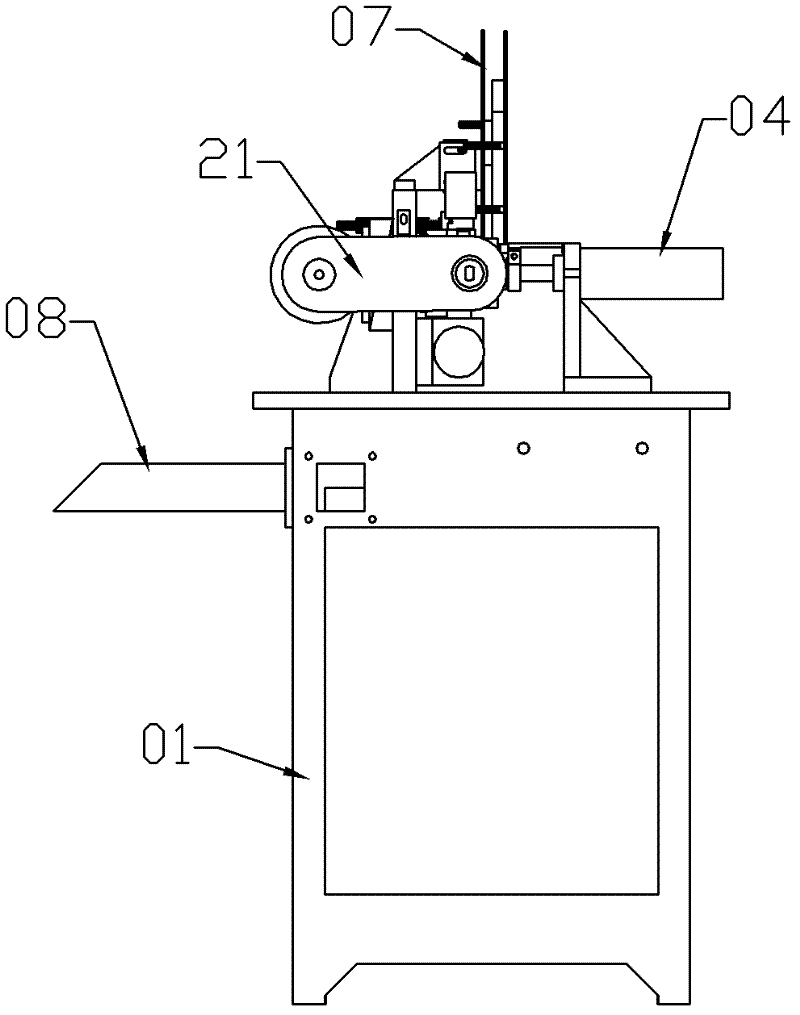

[0017] At first introduce the ferrule punching machine that is suitable for the inventive method, as Figure 1-3 , Figure 6 As shown, it includes at least one punching device 21 and 22 on the frame 01 pointing to the punching station (the figure shows two, arranged at 180°, during specific implementation, the number of holes that can be processed according to the needs Layout punching device), the punching station is defined by the backing 03 on one side and the clamping device 04 on the other side and can be close to and away from the backing 03, the clamping device 04 is configured to punch The support frame 05 extended by the hole station, there is a blanking space between the support frame 05 and the backer 03 for the ferrule blanking after processing, and the push rod 06 is configured for the support frame 05. The upper side is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com