Rapid reducing method of catalyst

A catalyst and fast technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of large hydrogen consumption, long catalyst reduction time, etc., achieve short reduction time, save hydrogen, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

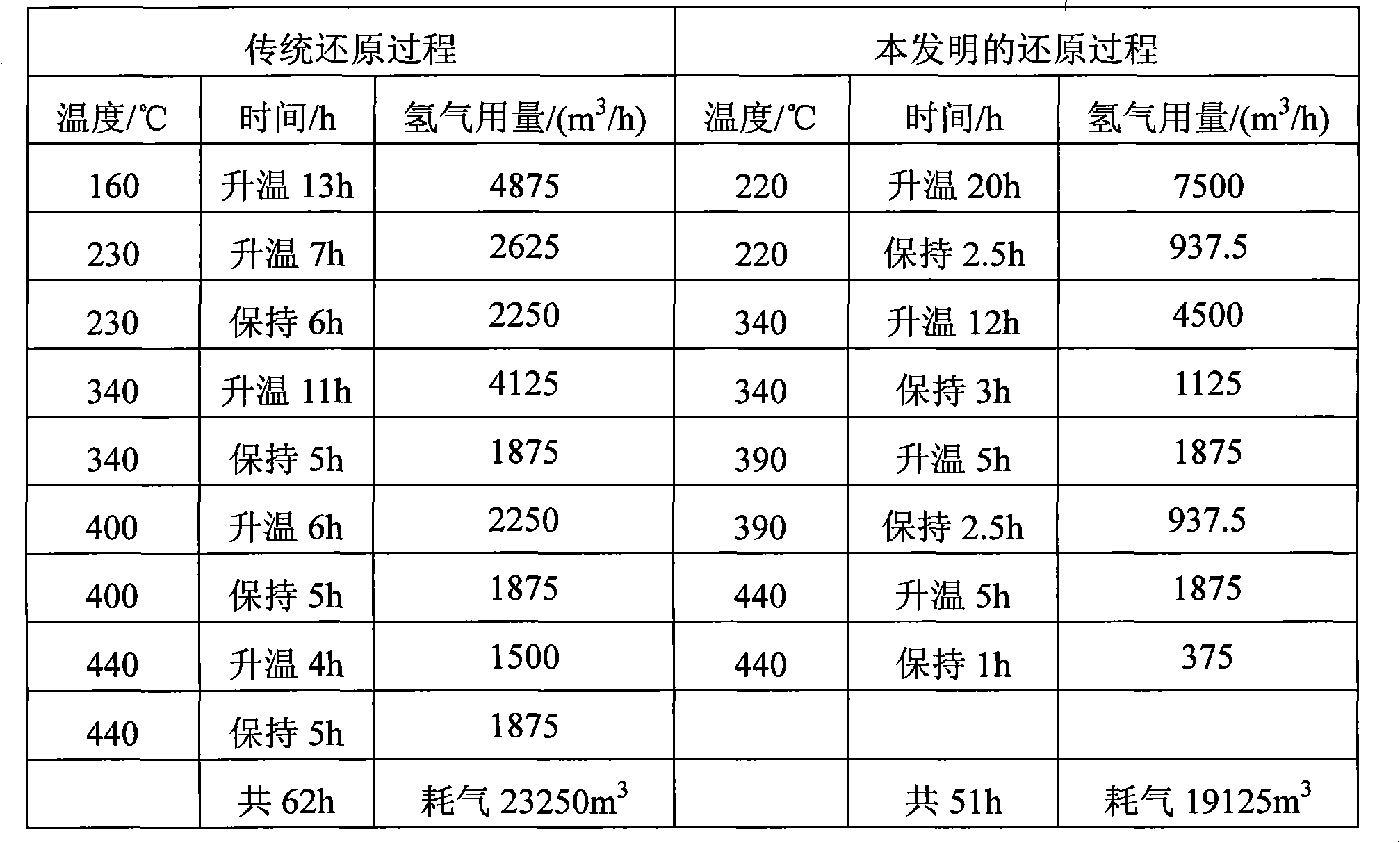

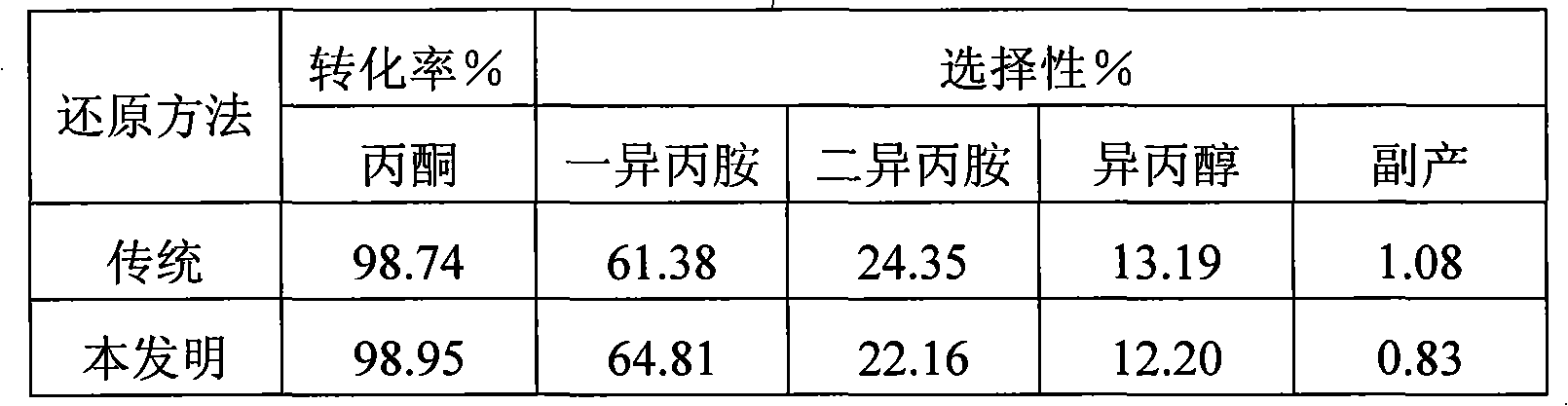

Embodiment 1

[0026] The method of the present invention is applied to the nickel-based catalyst reduction process. The loading amount of nickel-based catalyst is 1.0m 3 , the heating rate is 10℃ / h, and the gas flow rate at the inlet of the reduction furnace is 500m 3 / h, the hydrogen concentration is 75%, and the specific steps of the traditional reduction method and the method of the present invention are shown in Table 1. The reduced catalyst is at 152°C and the volume space velocity of acetone is 0.5h -1 , Acetone: hydrogen: the mol ratio of ammonia is 1: 3: 3, and the evaluation result on the isopropylamine evaluation device that catalyst consumption is 50ml is shown in Table 2.

[0027] The specific operation of the method of the present invention is as follows: the heating rate of the reduction furnace is set to be 10° C. / h, and the inlet gas flow rate is 500 m 3 / h, the hydrogen concentration is 75%, turn on the reduction control program to increase the temperature, and analyze t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com