Mid-infrared fiber laser

A laser, infrared light technology, applied in the laser field, can solve the problems of low oscillation efficiency, complex, unsuitable for field or airborne use, etc., and achieve the effect of improving conversion efficiency and output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

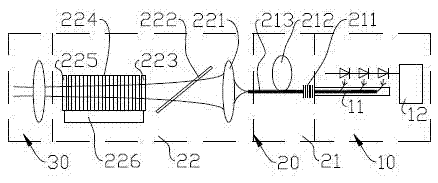

[0019] The present invention will be further described below in combination with specific embodiments. Such as figure 1 Shown is an embodiment of the mid-infrared fiber laser of the present invention, including a pre-pumping system 10 , a resonant cavity 20 and an output system 30 . The resonant cavity 20 is composed of a gain system 21 and an optical parametric oscillation system 22 . The gain system 21 includes a fiber grating 211 , a gain fiber 212 and a passive fiber 213 connected to each other, and the fiber grating 211 is connected to the pumping system 10 through an optical fiber. The optical parametric oscillation system 22 includes a focusing lens group 221, a Brewster polarizer 222, a nonlinear optical crystal 224, a short-pass filter 223 arranged in front of the nonlinear optical crystal 224, and a short-pass filter 223 arranged in front of the nonlinear optical crystal 224. Long pass filter 225. The light beam output from the passive optical fiber 213 enters the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com