Design and manufacturing method for anti-counterfeit electronic label, anti-counterfeit electronic label and anti-counterfeit packaging

A technology of electronic tags and symmetrical vibrators, which is applied in the direction of computing, computer parts, and record carriers used by machines, etc. It can solve the problem of anti-counterfeiting and anti-smuggling of single products that cannot be applied to electronic tags, reduce the anti-counterfeiting effect of RFID electronic tags, and damage products. Integrity and other issues to achieve the effect of improving anti-counterfeiting performance, reducing the probability of accidental damage, and reducing the difficulty of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

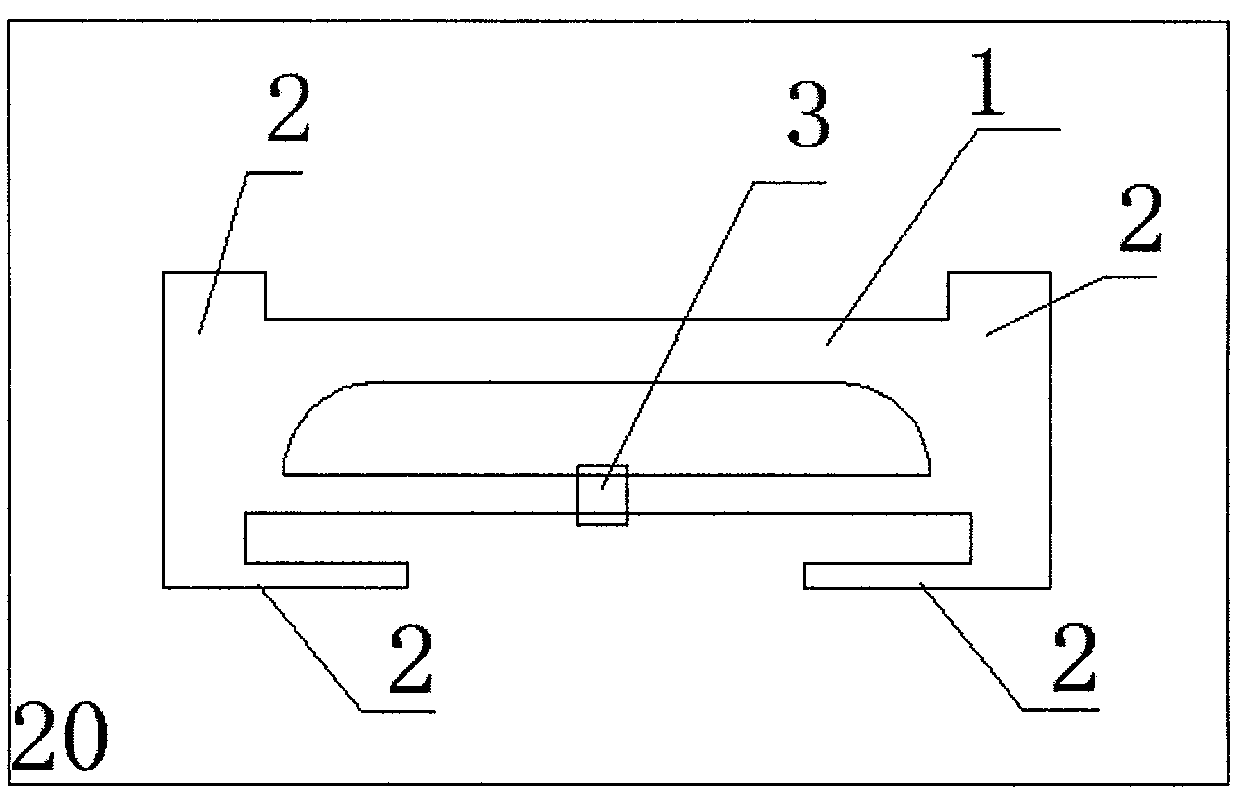

[0029] The following is a specific application example of the present invention, which is an ultra-high frequency UHF passive RFID tag that uses fragile paper to make anti-metal:

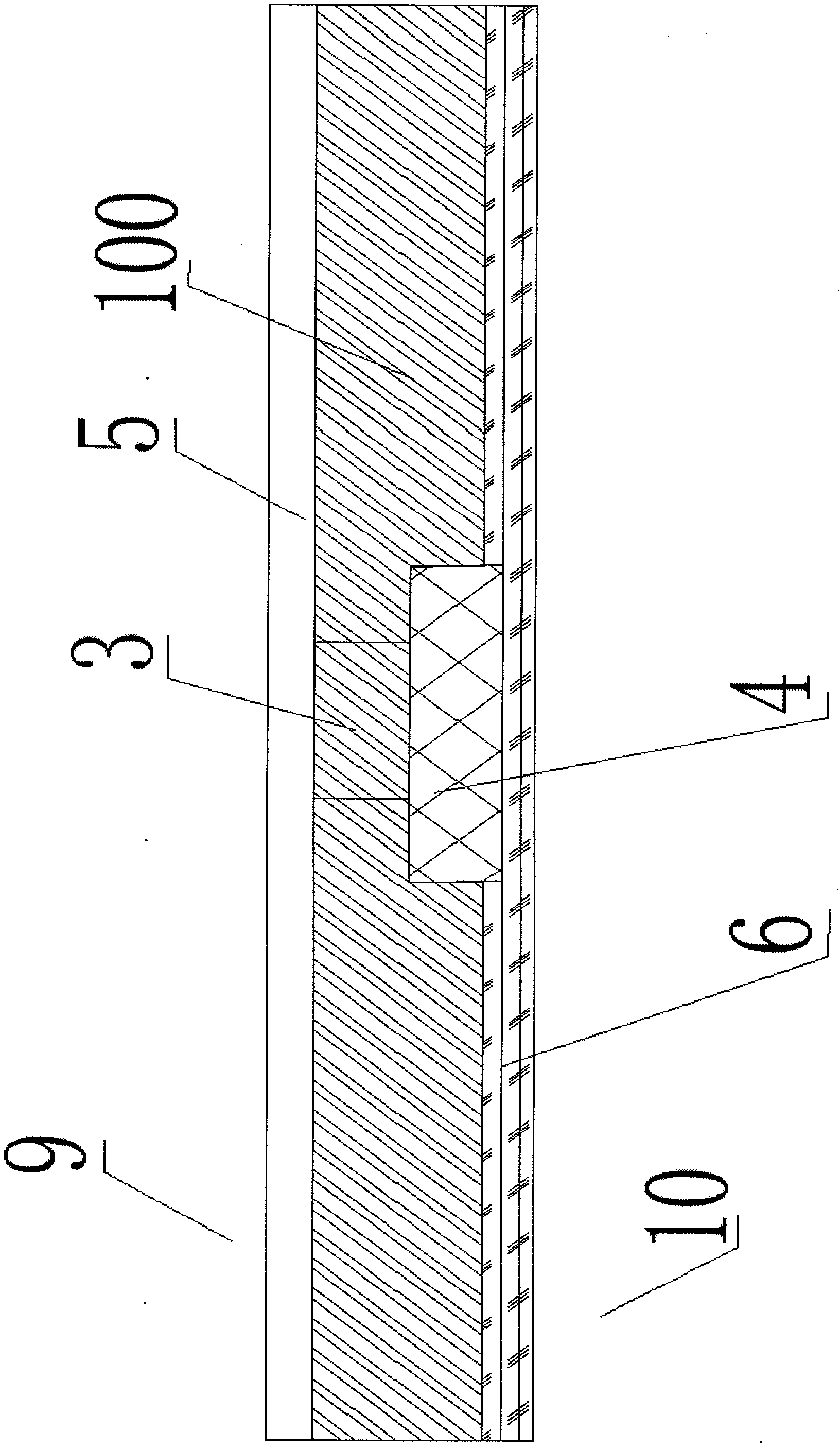

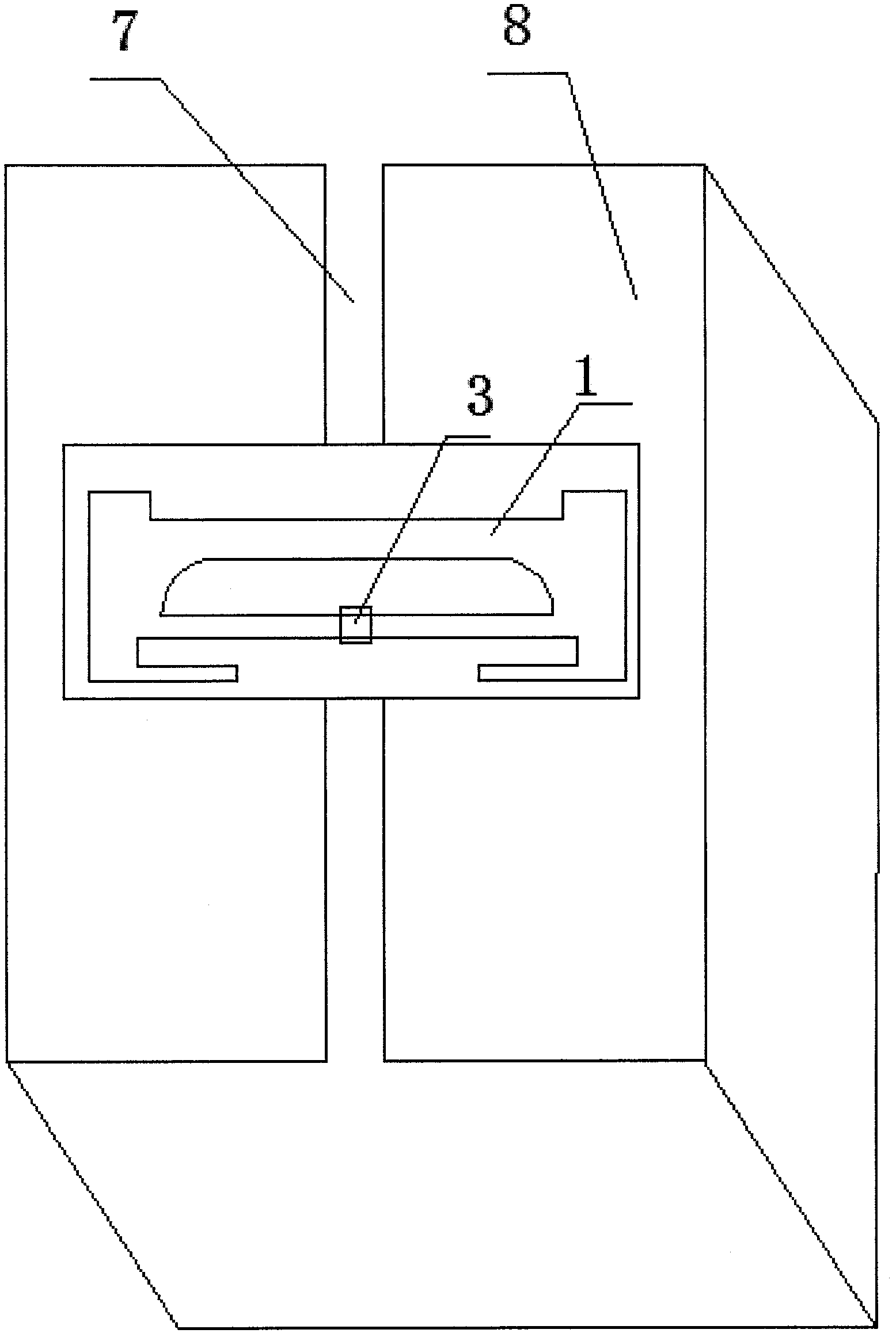

[0030] 1. The shape and physical characteristics of the marked object: the ultra-high frequency UHF passive RFID tag is attached to the packaging box printed on aluminum foil or aluminized paper. There will be a gap 7 in the middle of the box, and the labels cover both sides of the gap, such as image 3 shown.

[0031] 2. The use effect to be achieved by the application: the antenna of the fragile paper label should be completely destroyed when the box is opened.

[0032] 3. Antenna material: low-temperature curing printing silver paste (thickness 3-20um) (90 degrees Celsius for half an hour) printing screen 280Mesh.

[0033] 4. Antenna substrate: fragile paper 100um ~ 200um (dielectric constant Er < 3), storage temperature 5 ~ 40 degrees Celsius, humidity: greater than 40%.

[0034] 5. Size: rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com