Control method for preventing multi-unit air conditioner screw compressor from liquid impact

A technology of screw compressors and screw compressors, applied in the direction of machines/engines, refrigerators, refrigeration components, etc., can solve problems such as poor operation stability and safety, damage to compressor rotors, paralysis of air-conditioning systems, etc., and achieve stable operation Good performance and safety, and the effect of preventing liquid shock phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

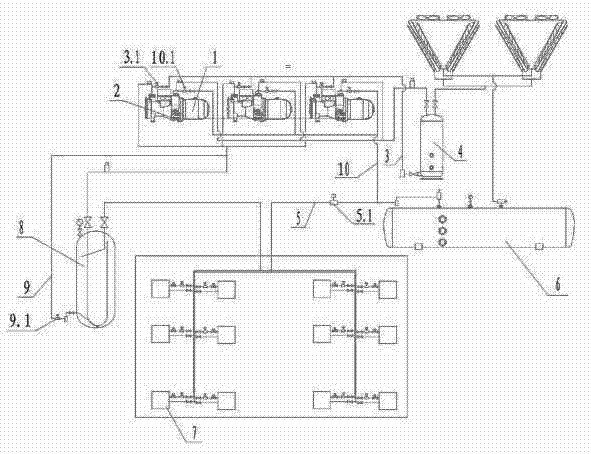

[0022] As shown in the drawings, the screw compressor multi-connected air conditioner of the present invention includes an outdoor unit and a multi-connected indoor unit, and the outdoor unit includes three screw compressors 1, an oil-gas separator 4, a high-pressure liquid accumulator 6 and a gas-liquid Separator 8, the oil pools of the three screw compressors 1 are provided with a balance pipe connection, between the bottom of the oil-gas separator 4 and the air return pipe of the compressor, oil return pipes 3 and return pipes respectively to the air return pipes of the respective compressors are installed. The oil solenoid valve 3.1 is used to send the lubricating oil at the bottom of the oil-gas separator 4 to the air return pipe of the compressor; a gas-liquid separator returning to the main air return pipe of the compressor is installed between the bottom of the gas-liquid separator 8 and the air return pipe of the compressor The oil return pipe 9 and the electromagnetic...

Embodiment 2

[0030] A control method for preventing liquid hammering of multi-connected air conditioner screw compressors comprises the following steps.

[0031](1) When the air conditioner unit is in the power-on standby state, the main liquid supply solenoid valve 5.1 on the main liquid supply pipe 5 is in the closed state, and the liquid supply solenoid valve 7.2 on the liquid supply pipe of each indoor unit 7 is in the closed state, and the oil and gas The oil return solenoid valve 3.1 on the oil return pipe 3 on the separator 4 is in a closed state, the liquid injection solenoid valve 10.1 on the liquid spray pipe 10 is also in a closed state, and the opening degree of the electronic expansion valve 7.1 of each indoor unit 7 is zero step;

[0032] (2) Before the air conditioner unit is turned on, the oil heater 2 in the oil pool of the screw compressor 1 is always on and heated. When the oil temperature in the oil pool of the screw compressor 1 reaches the set oil temperature, the set...

Embodiment 3

[0037] A control method for preventing liquid hammering of multi-connected air conditioner screw compressors comprises the following steps.

[0038] (1) When the air conditioner unit is in the power-on standby state, the main liquid supply solenoid valve 5.1 on the main liquid supply pipe 5 is in the closed state, and the liquid supply solenoid valve 7.2 on the liquid supply pipe of each indoor unit 7 is in the closed state, and the oil and gas The oil return solenoid valve 3.1 on the oil return pipe 3 on the separator 4 is in a closed state, the liquid injection solenoid valve 10.1 on the liquid spray pipe 10 is also in a closed state, and the opening degree of the electronic expansion valve 7.1 of each indoor unit 7 is zero step;

[0039] (2) Before the air conditioner unit is turned on, the oil heater 2 in the oil pool of the screw compressor 1 is always on and heated. When the oil temperature in the oil pool of the screw compressor 1 reaches the set oil temperature, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com