Fastening connection structure for mechanical parts

A technology for mechanical parts and fastening connections, applied in the direction of connecting components, mechanical equipment, threaded fasteners, etc., can solve the problems of waste of gasket production materials, complicated installation and fastening process, etc., and simplify the fastening and connection assembly process. , Material cost saving, considerable benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] like figure 1 Shown is a structural schematic diagram of the first embodiment of the present invention, a fastening connection structure of mechanical parts, including threaded fasteners 2 connecting at least two mechanical parts 1, and threaded fasteners are provided in the mechanical parts. The installation hole 3 is provided with an anti-slip structure on the mouth end surface 31 of the installation hole. The anti-slip structure includes several grooves 4 arranged on the mouth end surface of the installation hole, and the threaded fasteners are tightly pressed on the grooves after the mechanical parts are fastened and connected. In this embodiment, the grooves are arranged in a radial direction corresponding to the installation hole and are evenly distributed on the end surface of the installation hole.

[0021] According to the actual installation situation and needs, the grooves can be provided on the upper and lower ends of the mouth of the installation hole.

Embodiment 2

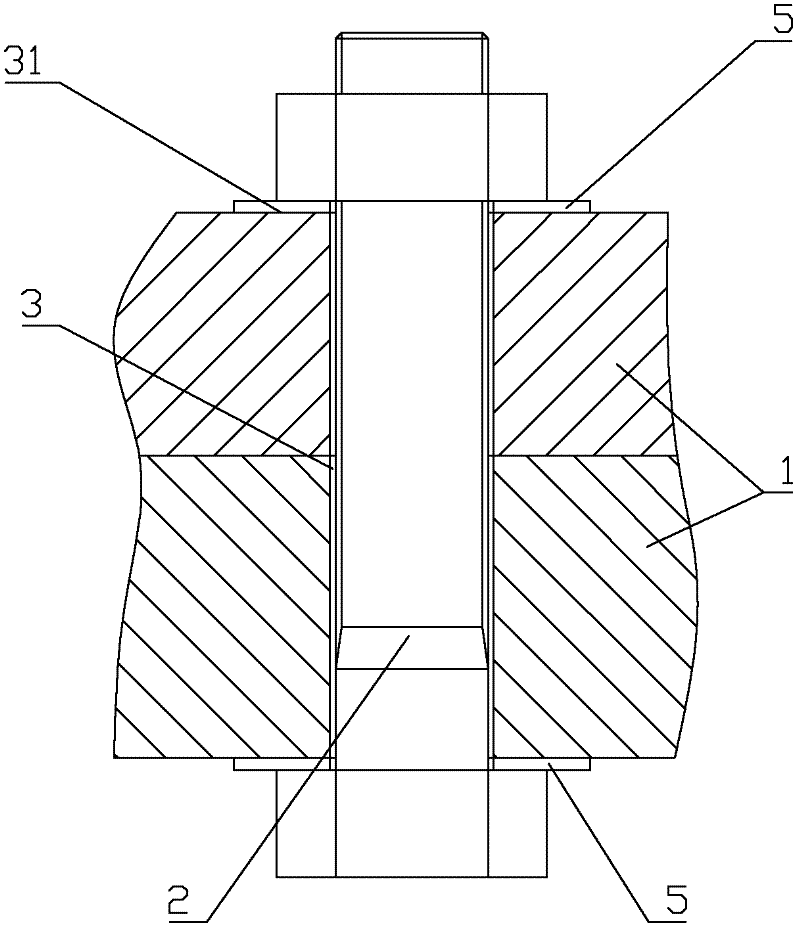

[0023] like figure 2 The structure schematic diagram of the second embodiment of the present invention is shown, the anti-slip structure includes several convex strips 5 arranged on the end face of the mouth of the installation hole, and the threaded fasteners are tightly pressed on the convex strips after fastening the mechanical parts. In this embodiment, the protruding lines are arranged in a radial direction corresponding to the installation hole and are evenly distributed on the end surface of the installation hole.

[0024] According to the actual installation situation and needs, convex lines can be provided on the upper and lower ends of the mouth of the installation hole.

Embodiment 3

[0026] Changes are made on the basis of Embodiments 1 and 2, such as image 3 The structural diagram of the third embodiment of the present invention is shown, a groove 4 is provided on the mouth end surface at one end of the installation hole, and a convex strip 5 is provided on the mouth end surface at the other end of the installation hole.

[0027] In all the above-mentioned embodiments, the threaded fasteners are bolts and nuts. Of course, internal threads can also be set in the mounting holes, and then bolts or screws can be used to thread the mounting holes for fastening, or double-ended studs and nuts can be used to realize mechanical fastening. Fast connections between parts. In the actual fastening connection, there may be higher requirements for preload between mechanical parts, so if image 3 As shown, an elastic washer is added. It is very convenient to adopt the structure of the present invention to realize the process of assembling and fastening connection wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com