Structure of a build-in screw in a bushing and corresponding sensor housing

A sensor housing and screw technology, applied in the direction of screws, nuts, connecting components, etc., to achieve the effect of easy use and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

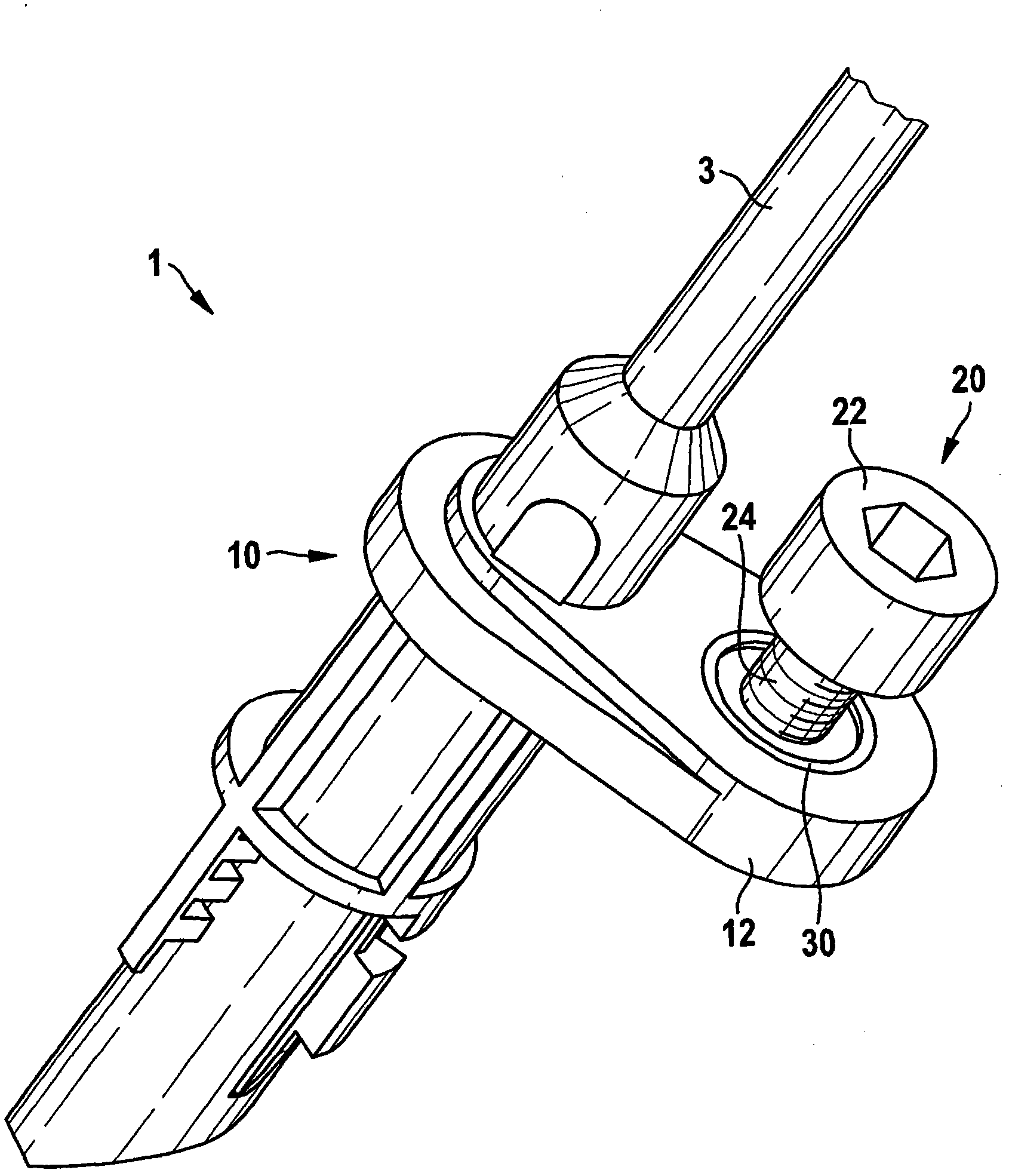

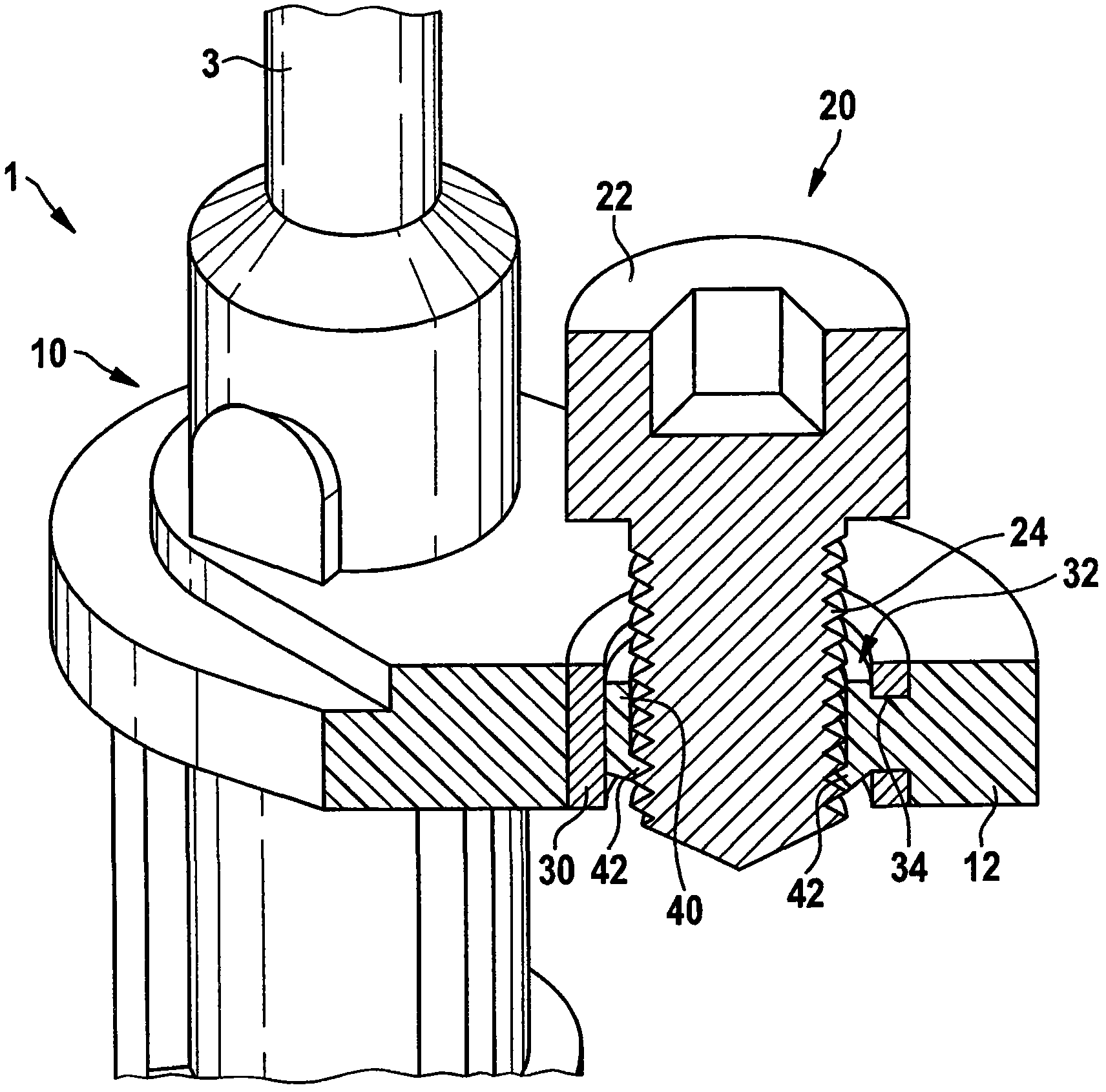

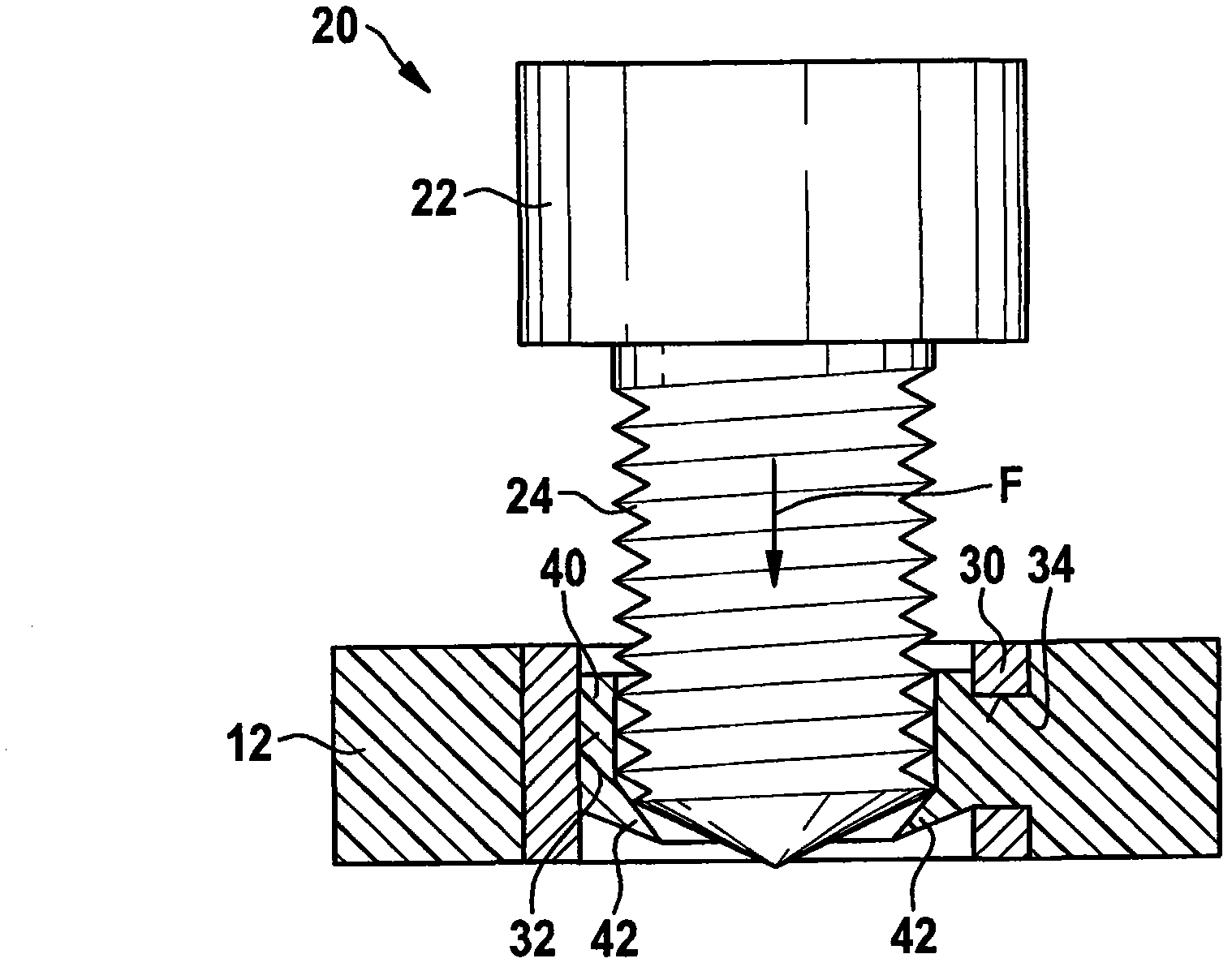

[0016] refer to Figures 1 to 4 , the illustrated embodiment of the invention utilizes the construction of a built-in screw 20 in a bushing 40 . The screw includes a head 22 and a threaded shank 24 . The screw head 22 is designed and arranged to turn the screw 20 , the screw head 22 here comprising, for example, a hexagonal recess for this purpose. The bushing 30 is fixedly connected to the fastening attachment 12 of the sensor housing 10 of the sensor unit 1 . In addition, the sensor unit 1 includes a connection cable 3 for electrically connecting a sensor element (not shown) inside the sensor housing 10 . Preferably, the sensor housing 10 is an injection-molded part, wherein the metal bushing 30 is used as an insert in a corresponding injection-molding process.

[0017] According to the invention, the bushing 30 is made of metal and comprises a portion 40 of elastic material at the inner region 32 in which the threaded shank 24 of the screw 20 deforms the flexible region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com