Foaming agent for sound absorption foam concrete product and preparation method for foaming agent

A technology for concrete products and sound-absorbing foam, which is applied in the field of foaming agents, can solve the problems affecting the performance of sound-absorbing products and the sound-absorbing effect is not ideal, and achieves the effects of better sound-absorbing effect, stable bubbles, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

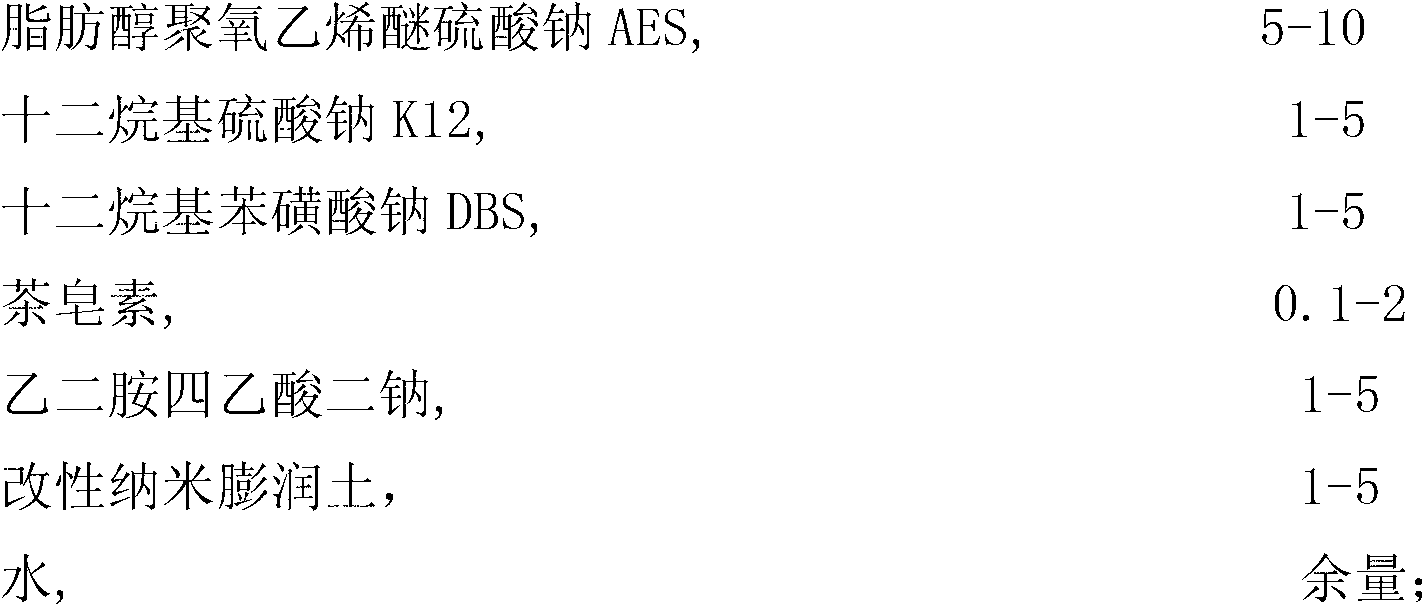

Embodiment 1

[0025] According to the mass ratio, it is fatty alcohol polyoxyethylene ether sodium sulfate (AES) 5-7%, sodium dodecyl sulfate (K12) 1%, sodium dodecylbenzenesulfonate (DBS) 3.5%, tea saponin 0.15% %, disodium ethylenediaminetetraacetic acid (EDTA) 2%, modified nano-bentonite 1.5% and the rest of the water to prepare raw materials. First add fatty alcohol polyoxyethylene ether sodium sulfate (AES) into an appropriate amount of water, heat and stir evenly in a water bath at a temperature of 30°C-50°C; then add sodium lauryl sulfate (K12), dodecylbenzene Sodium sulfonate (DBS), continue to stir until all materials are completely dissolved, and finally add tea saponin, disodium ethylenediaminetetraacetic acid (EDTA), modified nano-bentonite and the rest of the water.

Embodiment 2

[0027] According to the mass ratio, it is fatty alcohol polyoxyethylene ether sodium sulfate (AES) 5.5-7.5%, sodium dodecyl sulfate (K12) 2%, sodium dodecylbenzenesulfonate (DBS) 2.5%, tea saponin 0.3 %, disodium ethylenediaminetetraacetic acid (EDTA) 2.5%, modified nano-bentonite 2% and the rest of the water to prepare raw materials. First add fatty alcohol polyoxyethylene ether sodium sulfate (AES) into an appropriate amount of water, heat and stir evenly in a water bath at a temperature of 30°C-50°C; then add sodium lauryl sulfate (K12), dodecylbenzene Sodium sulfonate (DBS), continue to stir until all materials are completely dissolved, and finally add tea saponin, disodium ethylenediaminetetraacetic acid (EDTA), modified nano-bentonite and the rest of the water.

Embodiment 3

[0029] According to the mass ratio, it is fatty alcohol polyoxyethylene ether sodium sulfate (AES) 7-8%, sodium dodecyl sulfate (K12) 3%, sodium dodecylbenzenesulfonate (DBS) 1.5%, tea saponin 0.45% %, disodium ethylenediaminetetraacetic acid (EDTA) 3%, modified nano-bentonite 2.5% and the rest of the water to prepare raw materials. First add fatty alcohol polyoxyethylene ether sodium sulfate (AES) into an appropriate amount of water, heat and stir evenly in a water bath at a temperature of 30°C-50°C; then add sodium lauryl sulfate (K12), dodecylbenzene Sodium sulfonate (DBS), continue to stir until all materials are completely dissolved, and finally add tea saponin, disodium ethylenediaminetetraacetic acid (EDTA), modified nano-bentonite and the rest of the water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com