Bernoulli propeller

A propeller and screw connection technology, applied in the direction of rotating propellers, rotary propellers, etc., can solve problems such as propeller damage, easy hooking on algae, etc., and propeller stuck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

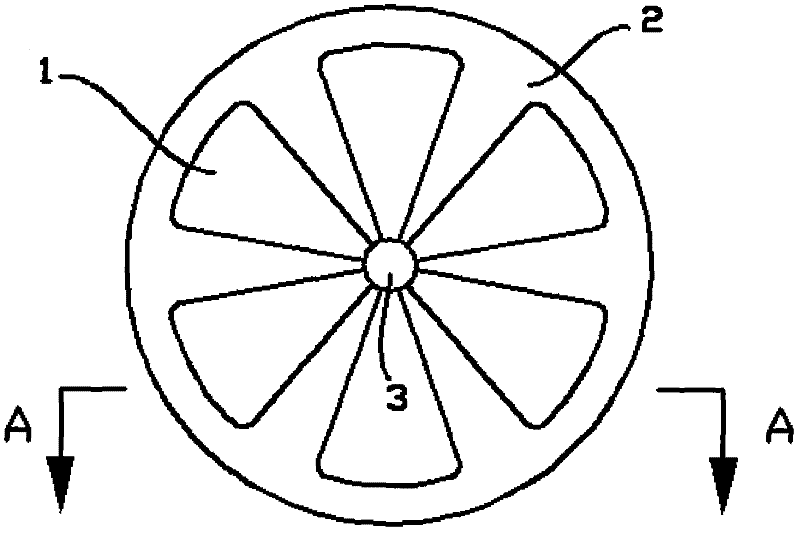

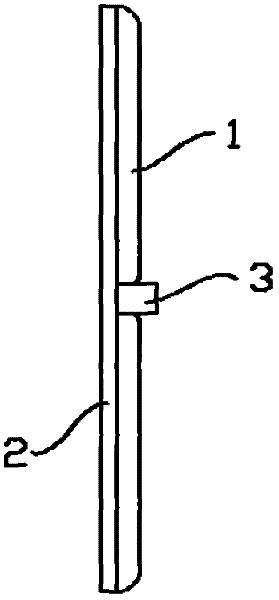

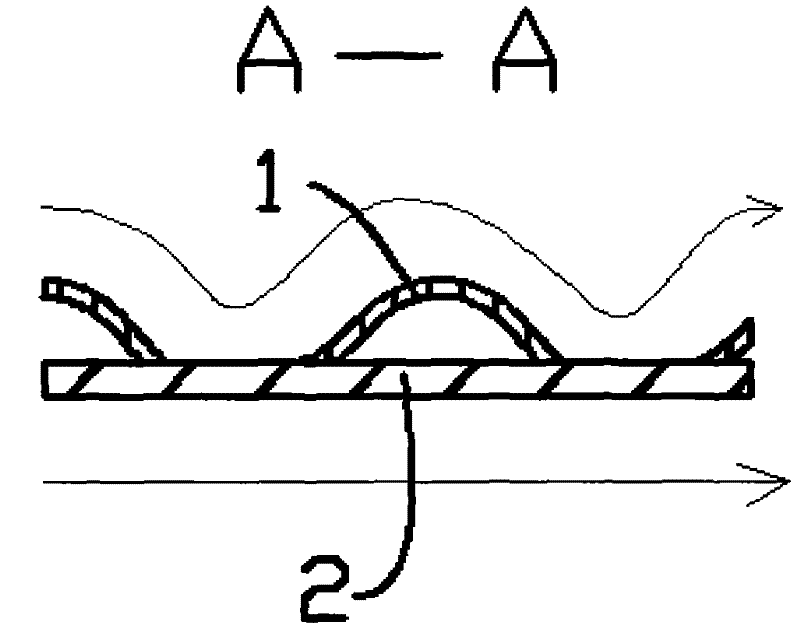

[0014] exist Figure 1-Figure 3 In the shown embodiment, the Bernoulli propeller includes a turntable 2, and the center of the turntable 2 is provided with a rotating shaft connecting body 3. The front of the turntable 2 is a plane, and the back has an arc-shaped surface 1 uniformly distributed in the circumferential direction.

[0015] In the aforementioned Bernoulli propeller, the arc-shaped surface 1 is an arc-shaped surface, such as image 3 As shown, it is made of thin metal sheet, extending from the outer edge of the turntable 2 to the center of the turntable 2, and has a shape of wide outside and narrow inside, as shown in figure 1 As shown, the metal sheet can be connected to the turntable 2 by welding, screwing or riveting.

[0016] For the aforementioned Bernoulli propeller, the turntable 2 is made of an aluminum plate, so that the propeller has a rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com