Preparation technique of wound dressing

A preparation process and technology for wound dressings, applied in the field of preparation of medical dressings, can solve the problems of limited drug-carrying properties of dressings, inability to meet industrial benefits, and inability to completely eliminate adhesion, and achieve good operation controllability, high tensile strength, Optimum effect of external contamination and bacterial entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 The specific preparation process of this wound dressing is as follows:

[0031] Using acrylic amide monomers and acrylic sulfonate monomers as cross-linking polymerization raw materials, glycerin as thickener and plasticizer, and difunctional esters with unsaturated double bonds as cross-linking The agent is polymerized and cross-linked by ultraviolet light to obtain a hydrogel material, and the hydrogel material is carried in a Teflon container, and then irradiated with ultraviolet light to obtain the wound auxiliary material.

[0032] The wound auxiliary material has a great swelling degree of 5000%. The surface of the hydrogel material is sticky. After absorbing water, its surface is non-sticky and will not stick to the wound. Keep trauma wounds in an optimal healing environment.

Embodiment 2

[0033] Embodiment 2 The specific preparation process of this wound dressing is as follows:

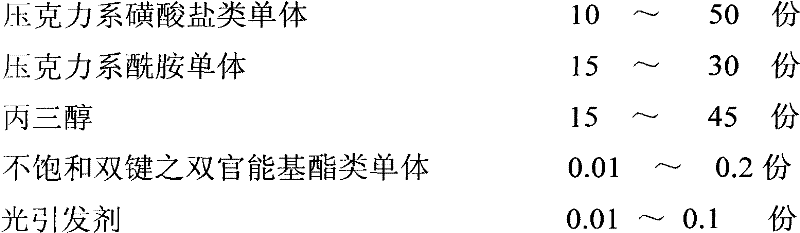

[0034] The material with the following weight ratio is used as raw material:

[0035]

[0036] First mix acrylic sulfonate monomers, acrylic amide monomers, and unsaturated double bond difunctional ester monomers, and add a photoinitiator to carry out cross-linking under ultraviolet light. Copolymerize to obtain hydrogel, add glycerol to the hydrogel and mix, and the mixed hydrogel is coated on the polyurethane elastic film for bonding to obtain the wound dressing.

[0037] After testing, the swelling degree of the wound dressing is about 5100%, the surface of the hydrogel is viscous, and the initial force can reach 1000nt / m 2 , the moisture absorption rate reaches 0.1ml / cm 2 / day, the gas exchange rate is 10000cm 3 / m 2 / day / atm. After absorbing water, the surface of the hydrogel is non-sticky and will not stick to wound tissue; the hydrogel has better tensile strength, and it...

Embodiment 3

[0038] Embodiment 3 The specific preparation process of the wound dressing is as follows:

[0039] The material with the following weight ratio is used as raw material:

[0040]

[0041]

[0042] The above-mentioned raw materials and drug components are mixed, coated on the polyurethane elastic film, and then cross-linked and polymerized by ultraviolet light, and the hydrogel is used as a drug carrier to obtain the wound dressing. The preparation process of the wound dressing is reasonable, and the operation is good in controllability. It can realize the high tensile strength of the wound dressing and the non-adhesive characteristics of the wound wound. It has good water absorption performance and has better characteristics of preventing external pollution and bacterial entry. The hydrogel used in the wound material can be used as a drug carrier to realize the drug. Embedding and carrying function. In a specific application, a hydrophilic layer can be coated on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com