Air purifying preparation and use thereof, air purifying preparation hanging bag and use thereof and production method of hanging bag

The technology of an air purifier and production method is applied in the directions of gasification, deodorization, disinfection, etc., and can solve the problems of cumbersome operation, inability to remove ammonia smell, odor, and inconvenience in practical use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

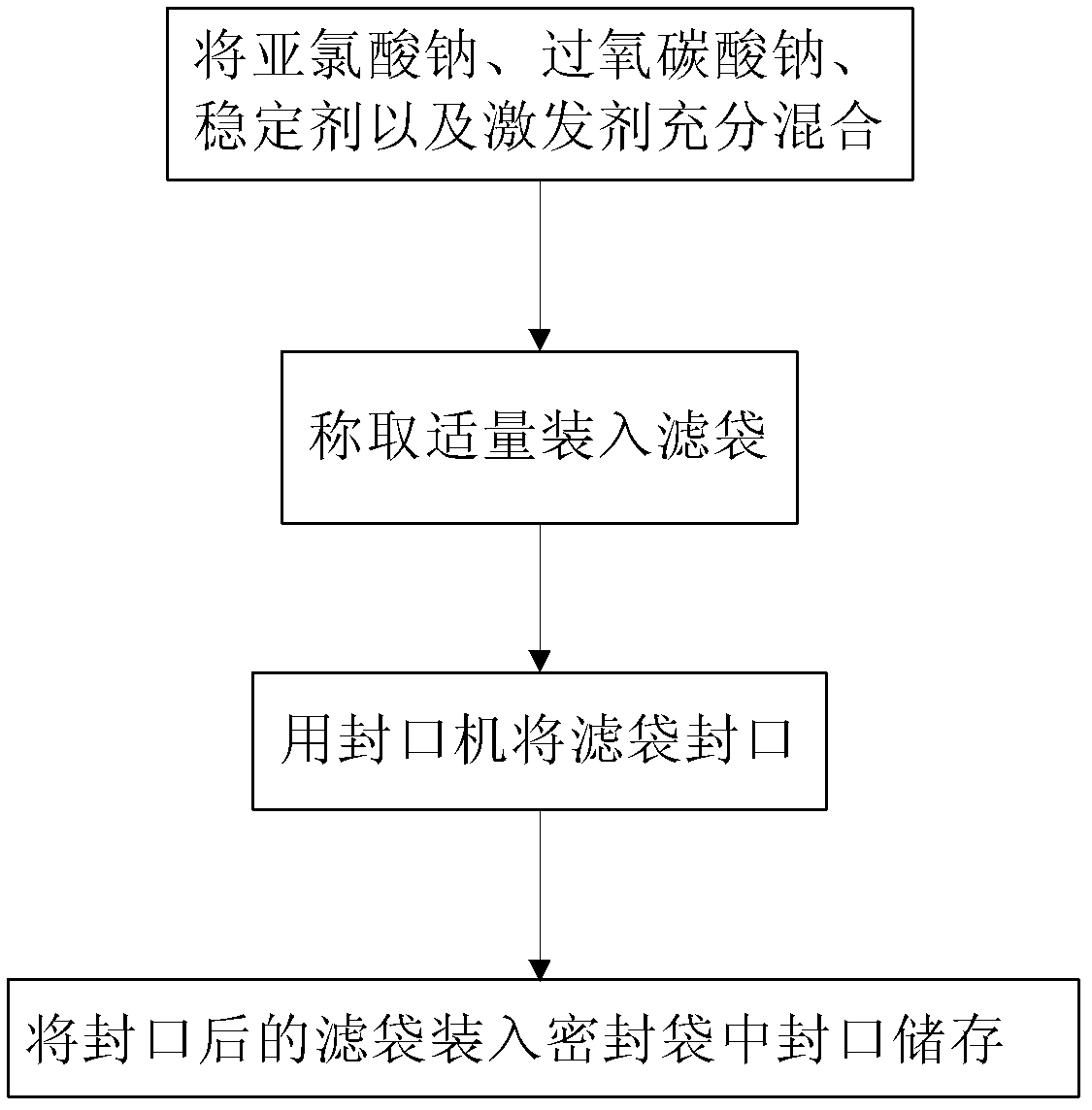

Method used

Image

Examples

Embodiment 1

[0036] Take by weighing sodium chlorite 16g, sodium percarbonate 2g, add stabilizer 30g (stabilizer composition: by weight percentage, sodium tartrate 1~15%, sodium bicarbonate 1~10%, sodium sulfate 10~30%, Magnesium sulfate 45~78%) after mixing uniformly, add activator 52g (activator composition: by weight percentage, citric acid 5~20%, sulfamic acid 40~85%, sodium bisulfate 10~40%) mix, Put it into a tea filter paper hanging bag to make an air purifier, and then put it into an aluminum foil bag and seal it for packaging. When in use, remove the air purifier from the aluminum foil bag, take a bag of air purifier (50g / bag), and place it in a relatively closed 200m 3 In the space, under the relative humidity of 65-80%, place it for 3 days, and check the total number of bacteria according to the inspection method of "GB / T18204.1-2000". The total number of bacteria is 3530 / m before placement 3 down to 210 / m 3 , the elimination rate is 94.05%, after 7 days, the total number of ...

Embodiment 2

[0038] Take by weighing sodium chlorite 16g, sodium percarbonate 2g, add stabilizer 30g (stabilizer is formed; In weight percentage, sodium tartrate 1~15%, sodium bicarbonate 1~10%, sodium sulfate 10~30%, Magnesium sulfate 45~78%) after mixing uniformly, add activator 52g (activator is formed; In weight percentage, citric acid 5~20%, sulfamic acid 40~85%, sodium bisulfate 10~40%) mixes, Put it into a tea filter paper hanging bag to make an air purifier, and then put it into an aluminum foil bag and seal it for packaging. When in use, remove the air purifier from the aluminum foil bag, take a bag of air purifier (25g / bag), and place it in a relatively closed 50m 3 In the space, under the relative humidity of 65-80%, place it for 8 hours, and check the ammonia concentration according to the inspection method of "GB / T18204.25-2000". The ammonia concentration dropped from 1450ppm to 50ppm, and the removal rate was 96.6%. After standing for 10 hours, the ammonia concentration drop...

Embodiment 3

[0040] Take by weighing sodium chlorite 16g, sodium percarbonate 2g, add stabilizer 30g (stabilizer composition: by weight percentage, sodium tartrate 1~15%, sodium bicarbonate 1~10%, sodium sulfate 10~30%, Magnesium sulfate 45~78%) after mixing uniformly, add activator 52g (activator composition: by weight percentage, citric acid 5~20%, sulfamic acid 40~85%, sodium bisulfate 10~40%) mix, Put it into a tea filter paper hanging bag to make an air purifier, and then put it into an aluminum foil bag and seal it for packaging. When in use, remove the air purifier from the aluminum foil bag, take a bag of air purifier (25g / bag), and place it in a relatively closed 50m 3 In the space, under the relative humidity of 65-80%, place it for 4 hours, and check the concentration of hydrogen sulfide according to the inspection method of "GB / T14678-93". The concentration of hydrogen sulfide drops from 500ppm to 5ppm, and the removal rate is 99%. After standing for 8 hours, the concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com