Jet soldering device and soldering method

A brazing and jetting technology, which is applied in the direction of tin feeding device, welding equipment, printed circuit assembly of electrical components, etc., can solve the problem of molten solder 2 residues, etc., and achieve the effect of reducing bridging phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, an embodiment of a jet brazing device and a brazing method according to the present invention will be described with reference to the drawings. However, the same reference numerals are assigned to the previously described elements, and descriptions thereof are appropriately omitted. Of course, the present invention is not limited to the embodiments described below.

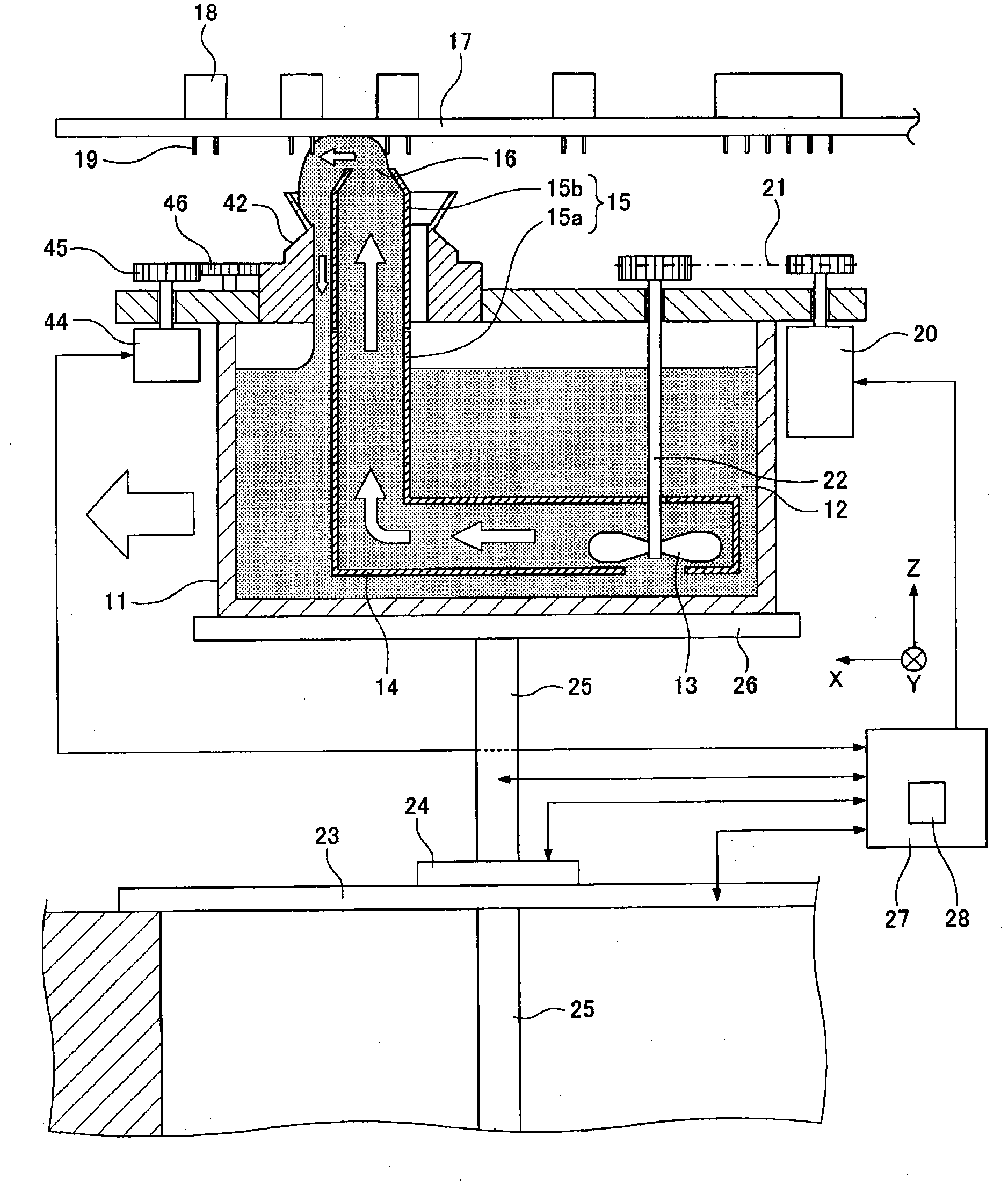

[0050] figure 1 It is a figure which shows the outline of one structural example of the jet soldering apparatus which concerns on embodiment of this invention. In this embodiment, the object to be soldered is a printed circuit board with through holes, and the soldered component to be soldered to the object to be soldered is an electronic component with leads. In addition, the objects to be soldered and the components to be soldered are not limited to printed circuit boards and electronic components.

[0051] Such as figure 1 As shown, the solder tank 11 contains molten solder 12 . By he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com