Apparatus and method for determining the loading and conveying rate of a bridge loader

A technology of conveying device and loader, which is applied in the direction of loading/unloading, measuring device, transportation and packaging, etc., and can solve problems such as small precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

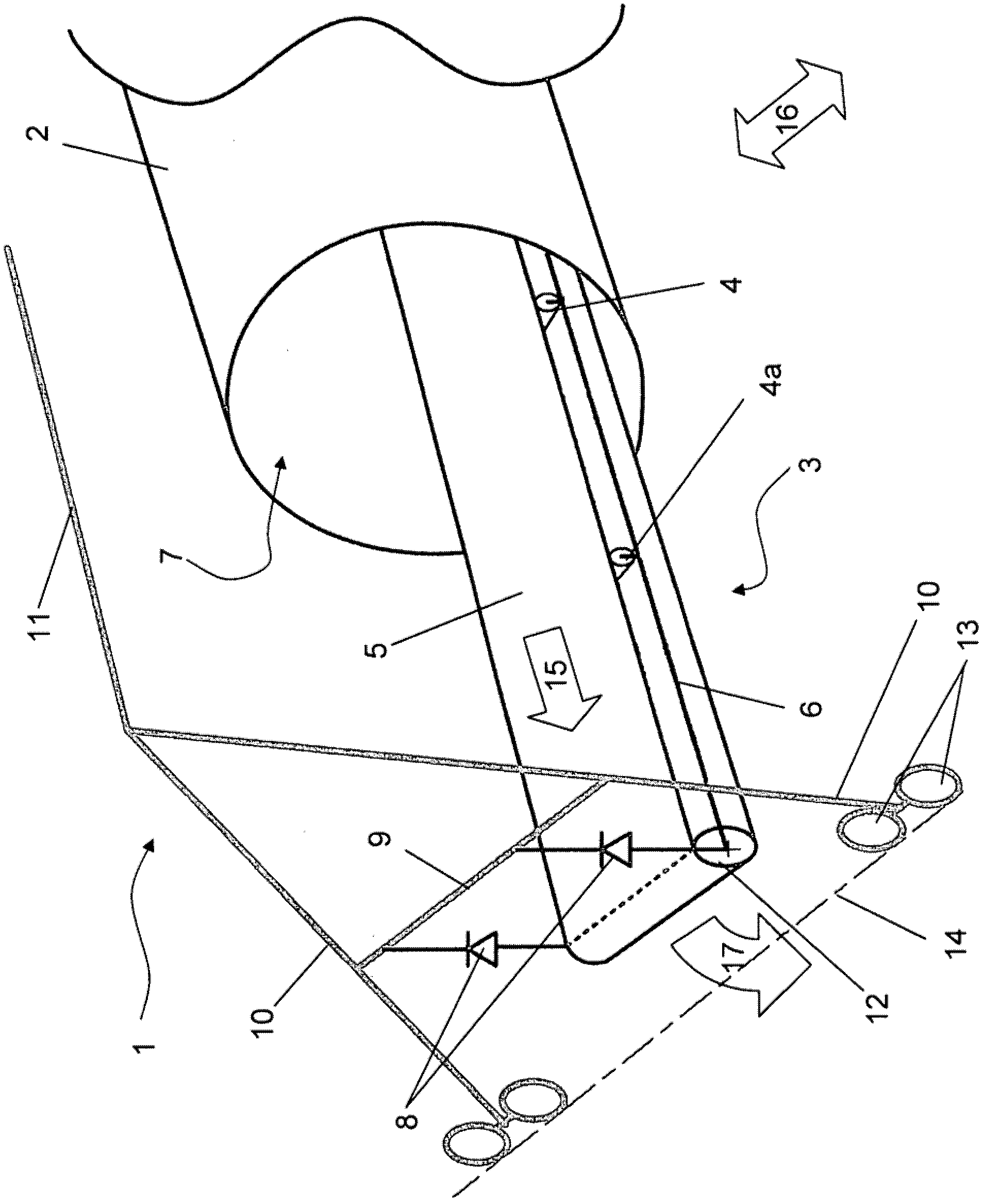

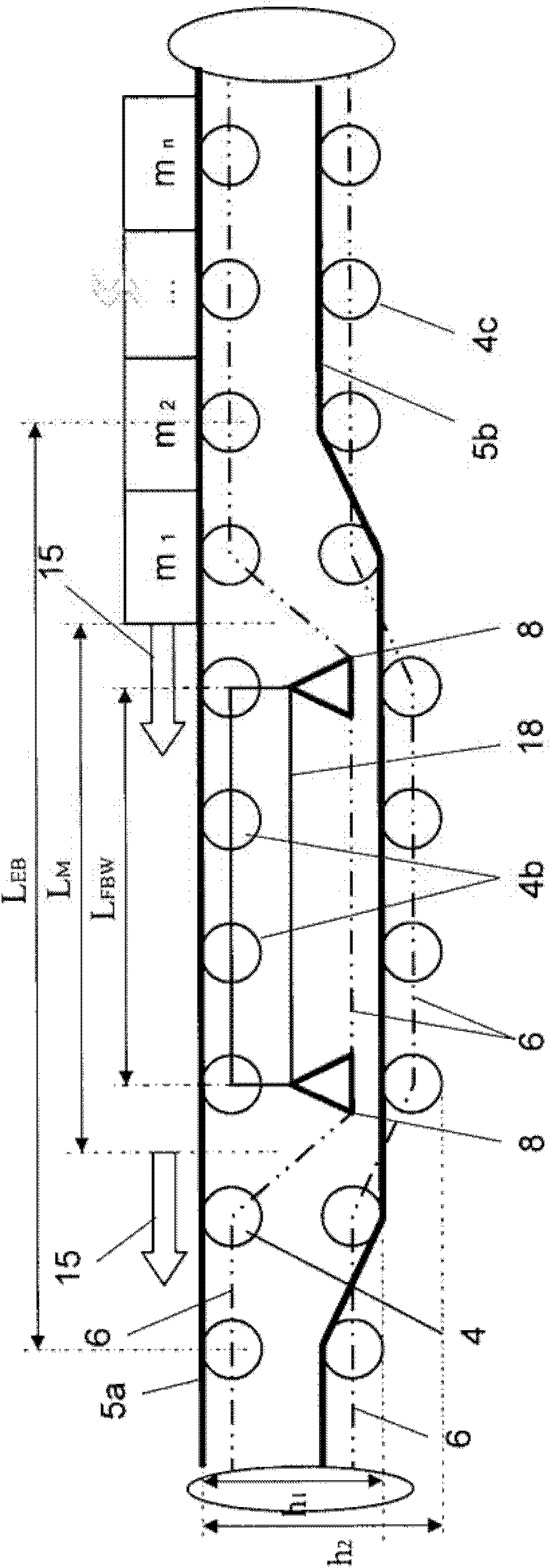

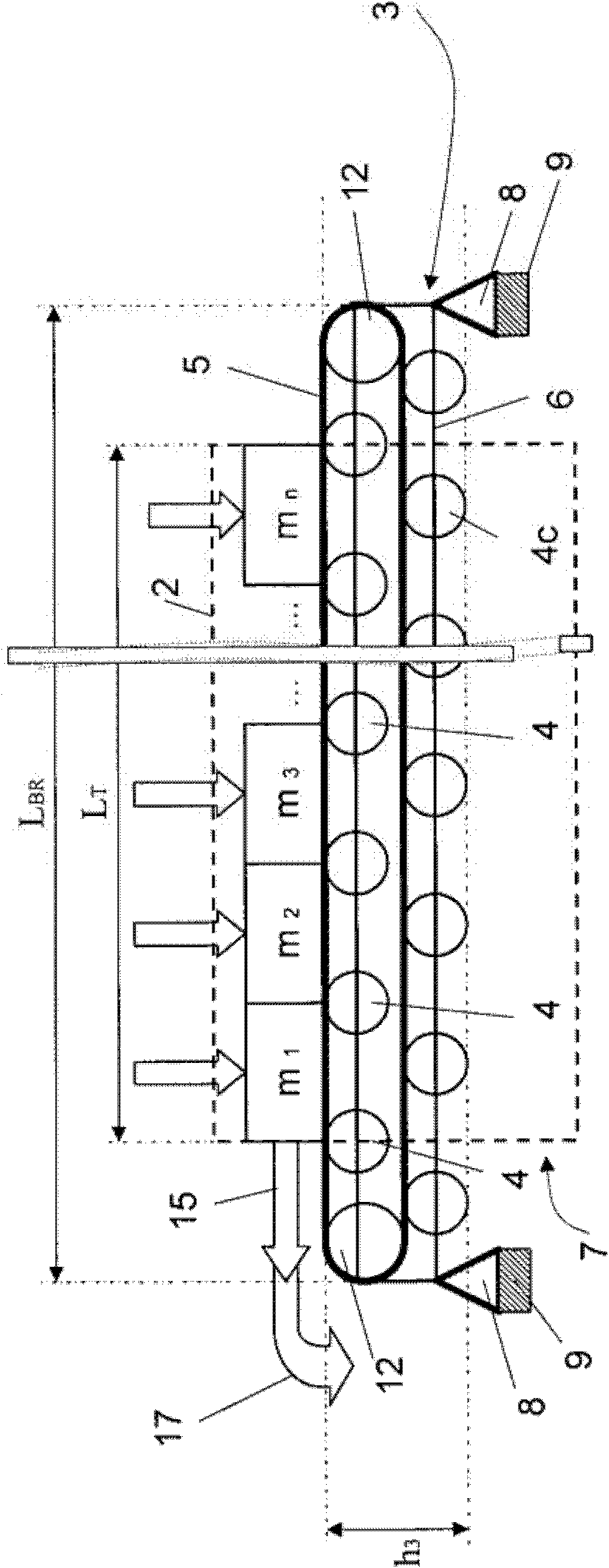

[0036] exist figure 1 shows schematically a part of a bridge loader with a device according to the invention for determining the load delivery rate, where in principle reference can be made to the previous definition of such a bridge loader and determined by This basically avoids repetition in the following description.

[0037] figure 1 A preferred embodiment of a roller bridge loader is shown in . The roller loader 1 comprises a rotary loading tool 2 rotatable about its horizontal axis, which is designed in the form of a loading feed roller, or simply a transfer roller. The diameter of such conveying scald is usually between 5 m and 6 m, for example, but can also be larger or smaller. The conveyor drum has a length which in turn defines the width of the mixed bed pile which can be loaded by it, onto which at least one loose material is poured. Typical lengths may span, for example, a 25 m to 45 m wide mixed bed stock, wherein such a mixed bed stock is not shown in the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com