Ultra-high temperature resistant internal rotor magnetic coupler without internal magnetism

A magnetic coupler and inner rotor technology, applied in electrical components, electromechanical devices, etc., can solve the problems of affecting work, large magnetic leakage losses, and high process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

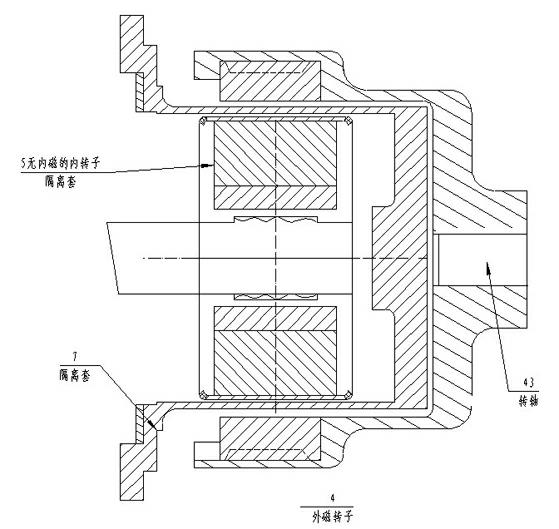

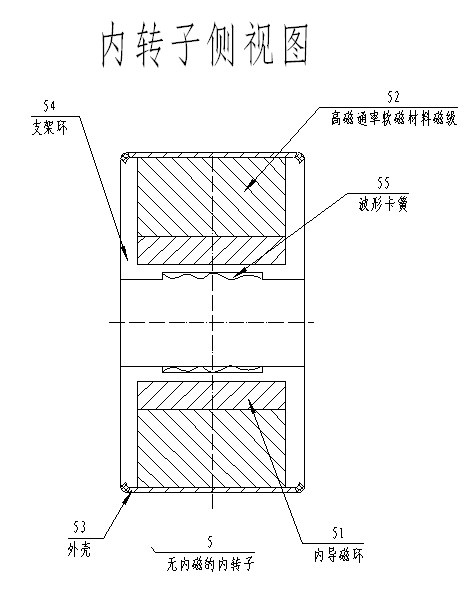

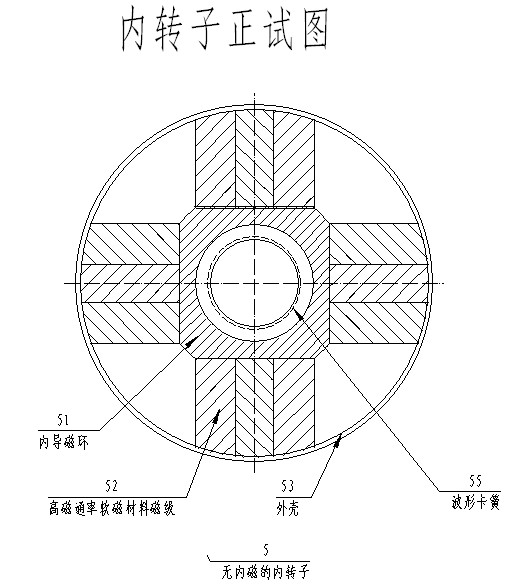

[0014] The present invention is realized in the following ways, combined with figure 2 illustrate:

[0015] The inner rotor (5) without internal magnetism according to the claim: 1. A new type of inner rotor without internal magnetism, mainly comprising: an inner magnetic conducting ring (51), a high magnetic flux rate 1J22 (national standard) The soft magnetic material is made of magnetic stage (52), 4 or more even-numbered magnetic poles, and each magnetic stage (52) is composed of 2-4 high-flux 1J22 soft magnetic materials of the same size combined into one magnetic pole, Since the 1J22 soft magnetic material has a Curie temperature of 980°C, the outer magnetic rotor (4) magnetized by the outer magnetic steel can be obtained in the medium liquid at a high temperature of 350°C to 500°C, and is in phase with the outer magnetic rotor (4) outer magnetic steel. Coupling, while the soft magnetic material is composed of 2-4 pieces of the same size, and has a strong magnetic fiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com