Method for synchronizing data acquired in hot continuous rolling process

A process and data collection technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of difficult quantitative establishment of control process, difficult application of analysis methods, and debugging and analysis of multi-stage time-varying and complex time-delay systems Or the difficulty of quality analysis and other issues, to achieve the effect of simple application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment implements under the premise of technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following embodiment.

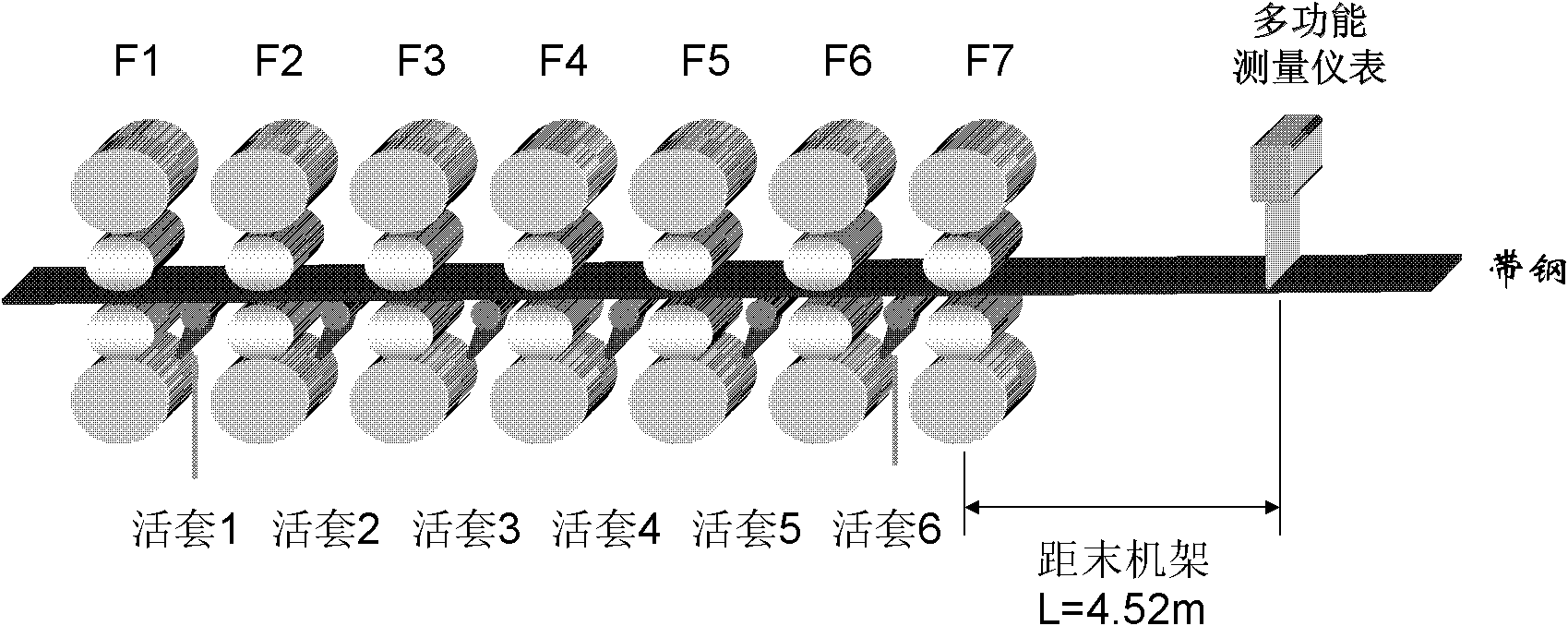

[0047] This embodiment is applied to the synchronous processing of the process data acquisition system of a seven-stand hot continuous rolling and finishing mill. Such as figure 1 As shown, there are seven racks in total, and the quality monitoring stage is from the last rack , the frame stiffness coefficient is .

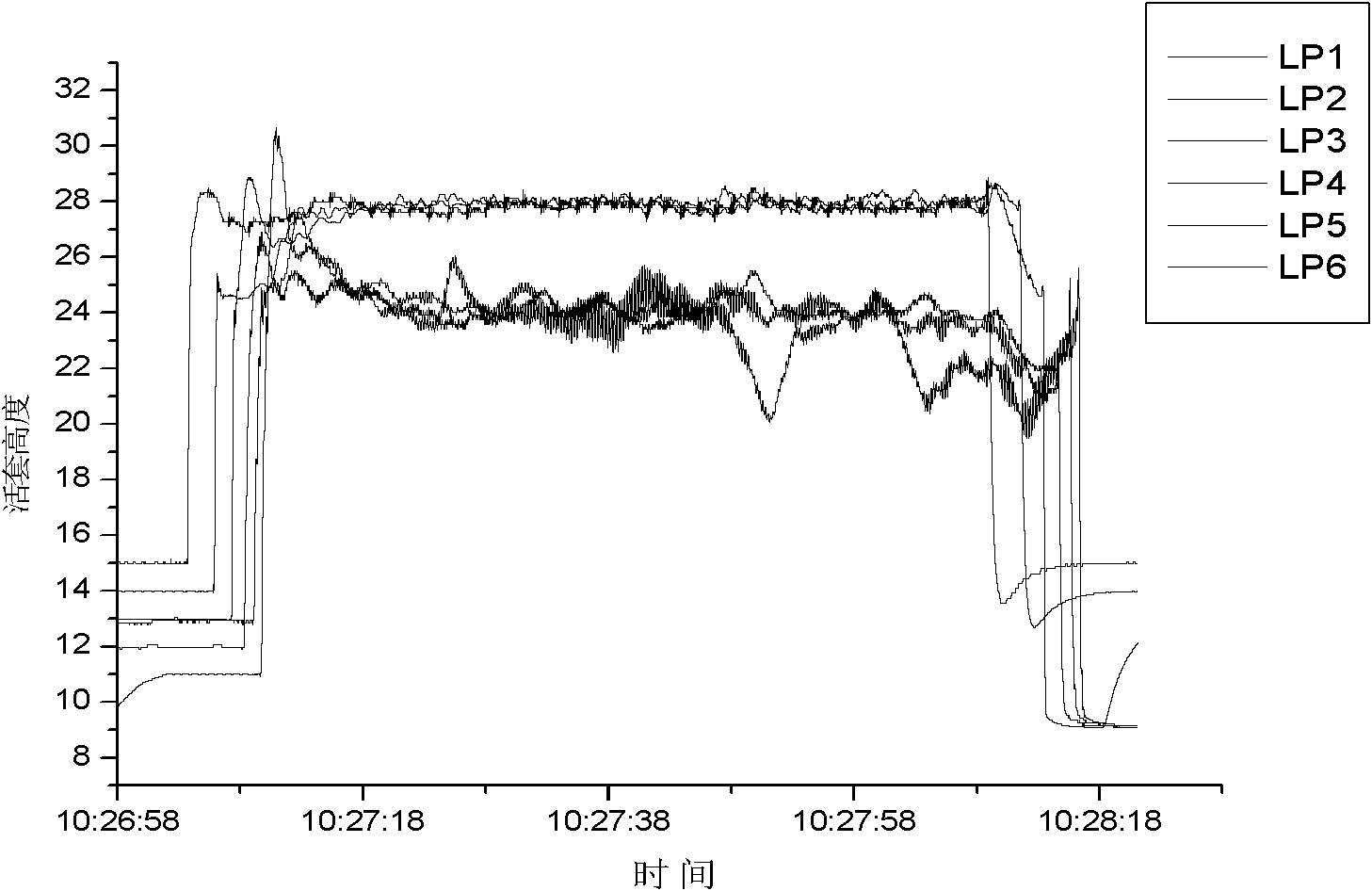

[0048] The high-dimensional control process variables and quality monitoring variables obtained from 7-stand monitoring, due to the multi-stage, time-varying, and time-delay effects of the manufacturing process, taking the rolling force observation variables as an example, the time-varying trend cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com