Device and method for calibrating valve direct current residual voltage parameter tester of zinc oxide arrester

A technology for calibrating devices and arresters, applied in measurement devices, instruments, measuring electrical variables, etc., can solve the problem of no special test device, etc., and achieve the effect of ensuring coverage and being convenient to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

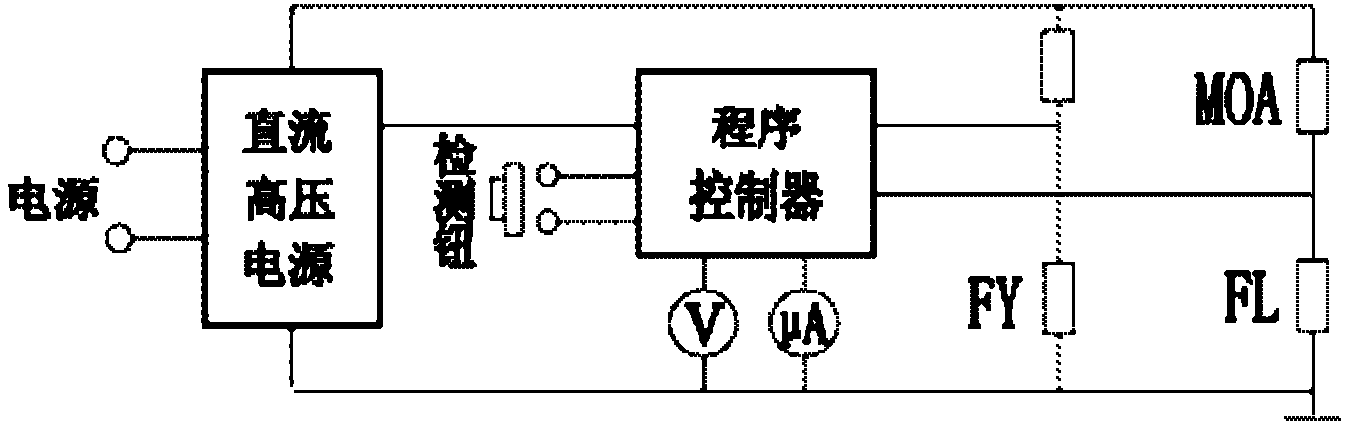

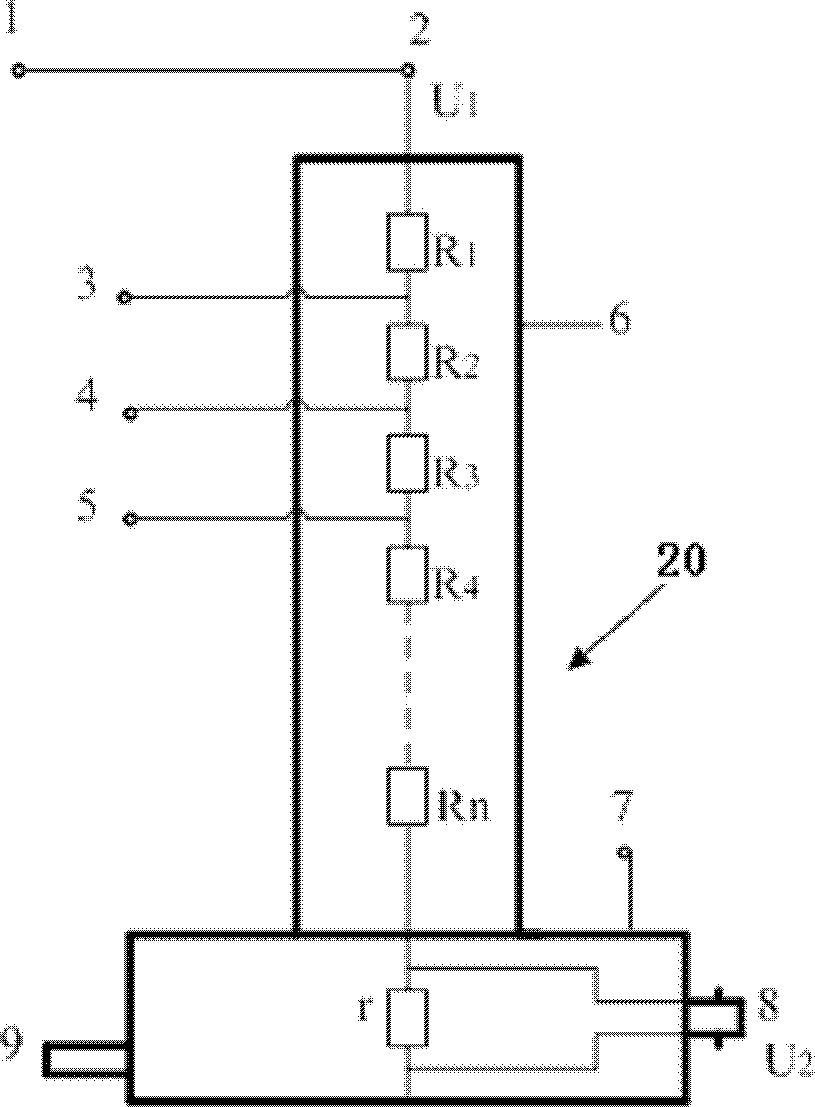

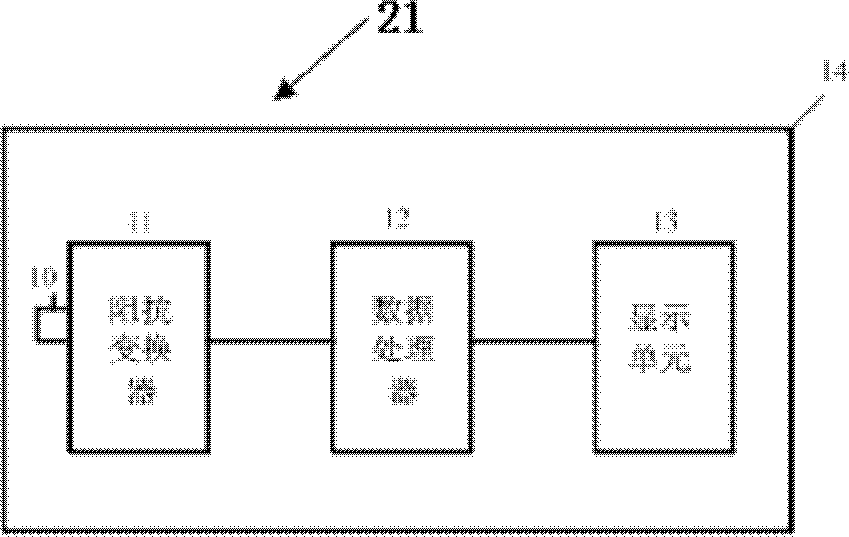

[0032] see figure 2 and image 3 As shown, a zinc oxide surge arrester valve plate DC residual voltage parameter tester calibration device of the present invention includes a standard resistance divider 20, a high-voltage connection line 1, a data processing and display unit 21 and a high-voltage interface.

[0033] see figure 2 As shown, the standard resistor divider 20 includes an epoxy resin insulating cylinder 6 and a base 7, the insulating cylinder 6 is fixed on the base 7, and the insulating cylinder 6 is provided with high-voltage arm resistors R connected in series. 1 , R 2 , R 3 , R 4 ,,,,,R n , high voltage arm resistance R 1 , R 2 , R 3 , R 4 ,,,,,R n Connect in series to form a high-voltage arm resistor string; high-voltage interface 2 is connected to the high-voltage arm resistor R 1 One end, the high voltage interface 3 is connected to the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com