Small-Abbe-error three-dimensional measurement system

A technology of Abbe error and three-dimensional measurement, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of Abbe error influence, limited measurement function, complicated operation, etc., to reduce the influence of force deformation error, reduce the Abbe error in Z direction and good detection repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

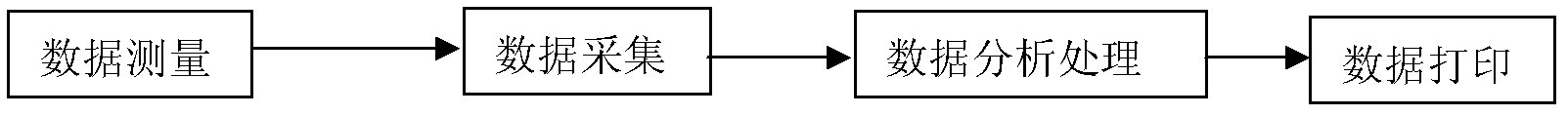

Image

Examples

Embodiment Construction

[0025] see figure 1 , figure 2 , in this embodiment, the mechanical transmission unit is set to have:

[0026] The X-direction assembly is to fix the X-direction rail 12 on the X-direction rail seat 26, and the X-direction slider 8 is slidably matched with the X-direction rail 12, and the X-direction slide seat 23 is fixedly installed on the X-direction slider 8;

[0027] Y-direction assembly, Y guide rail 5 is fixedly installed on Y guide rail seat 31, and Y-direction slide seat 10 and Y guide rail 5 slide fit; Y guide rail seat 31 and X-direction slide seat 23 are solidly connected; X-direction The upper surface of the guide rail 12 is on the same plane as the upper surface of the Y guide rail 5;

[0028] The Z-direction assembly is a Z-direction rail seat 21 with a Z-direction rail 16 fixedly installed on the Z-direction base 22, the Z-direction slider 17 is slidably matched with the Z-direction rail 16, and the Z-direction slide seat 2 is fixedly arranged on the Z-direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com