Electric injection ignition debugging device for motorcycle engine and control method thereof

An ignition control, engine technology, applied in the direction of engine control, electrical control, engine components, etc., can solve the problems of incomplete information display, rough control method, complex circuit structure, etc., to improve control accuracy, improve anti-interference ability, control The effect of strict logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

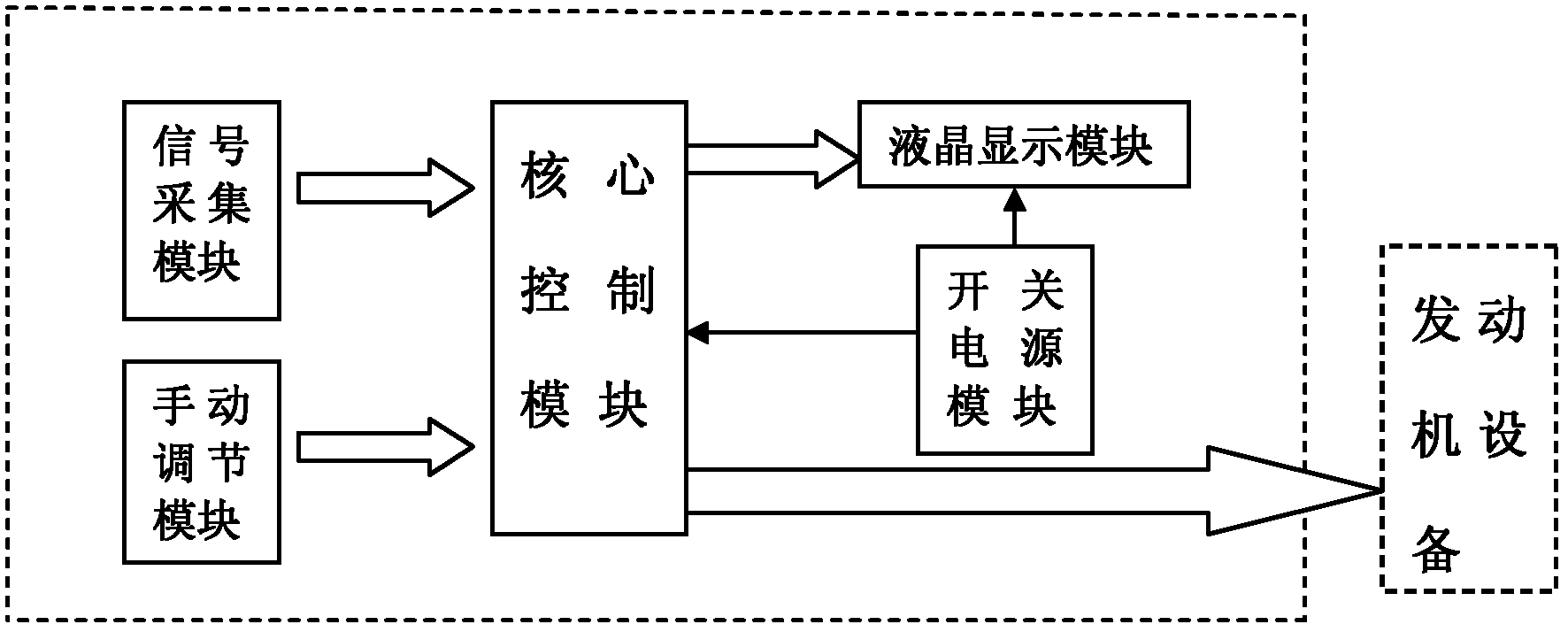

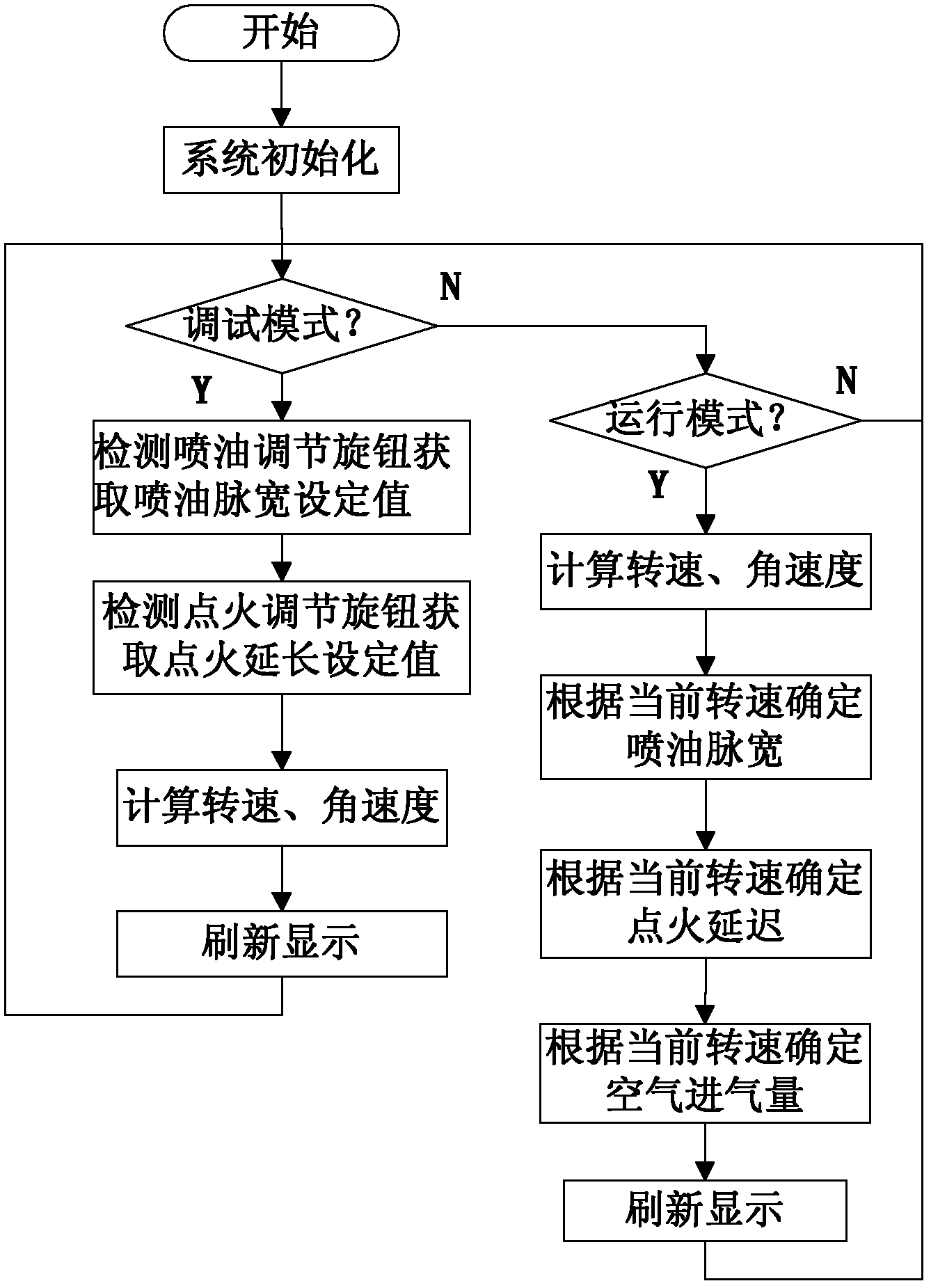

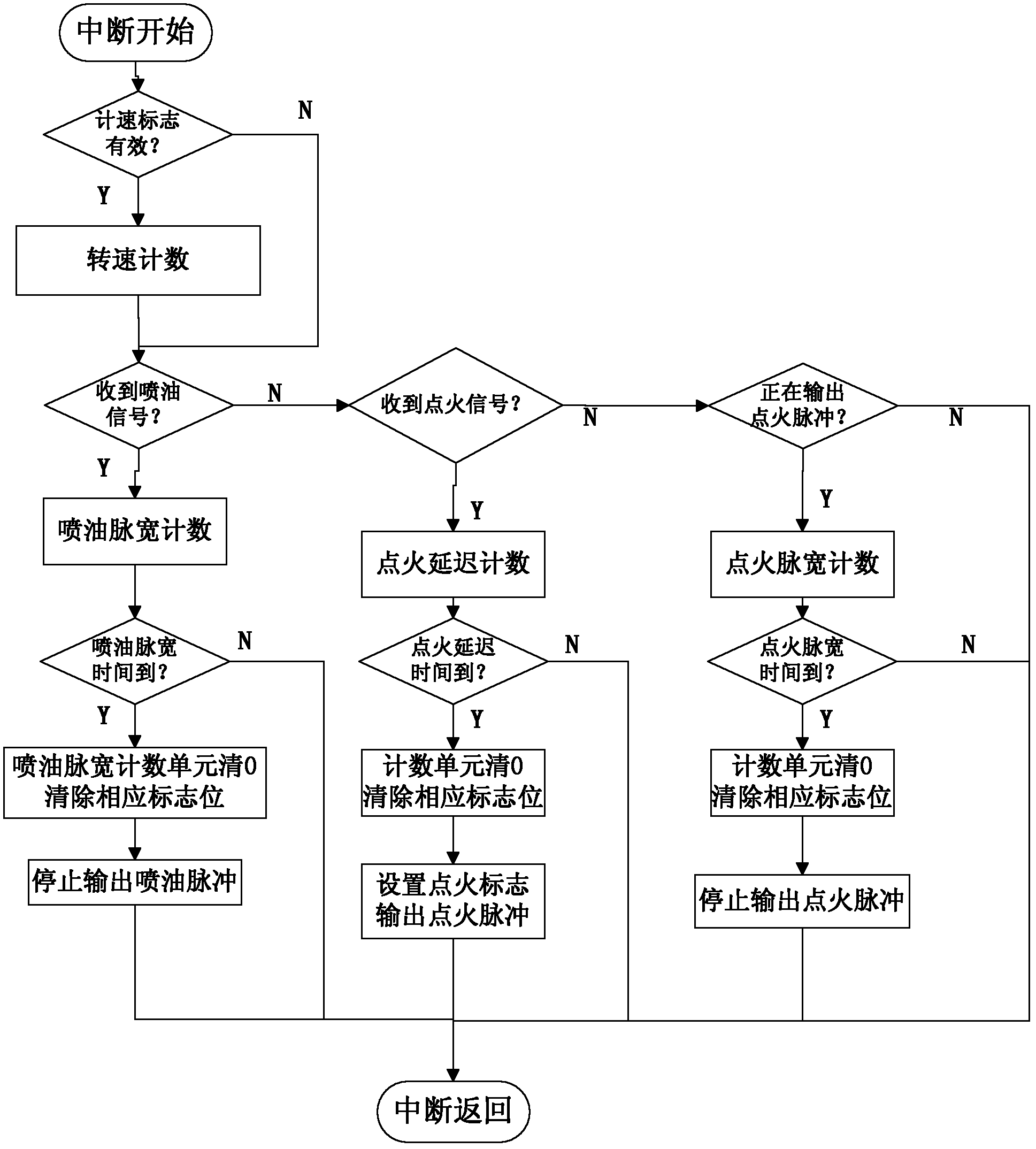

[0040] Such as figure 1 As shown, a motorcycle engine EFI ignition debugging device, including: a signal acquisition module, used to collect the current ambient temperature, and further calculate the speed and control the fuel injection pulse width, ignition delay angle, air intake volume for the core control module Provide relevant signals of the engine;

[0041] The core control module is used to analyze and process the acquired external signals according to different working modes, control the fuel injection pulse width, ignition delay angle, air intake volume according to the setting value of the manual adjustment knob or the determined control logic, and Send the processed data and collected raw data to the liquid crystal display module;

[0042] The liquid crystal display module is used for real-time display of the data transmitted by the core control module;

[0043] The manual adjustment module is used to manually adjust the ignition delay angle and fuel injection pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com